Electrolyte for battery, preparation method and application thereof, and lithium ion battery containing the same

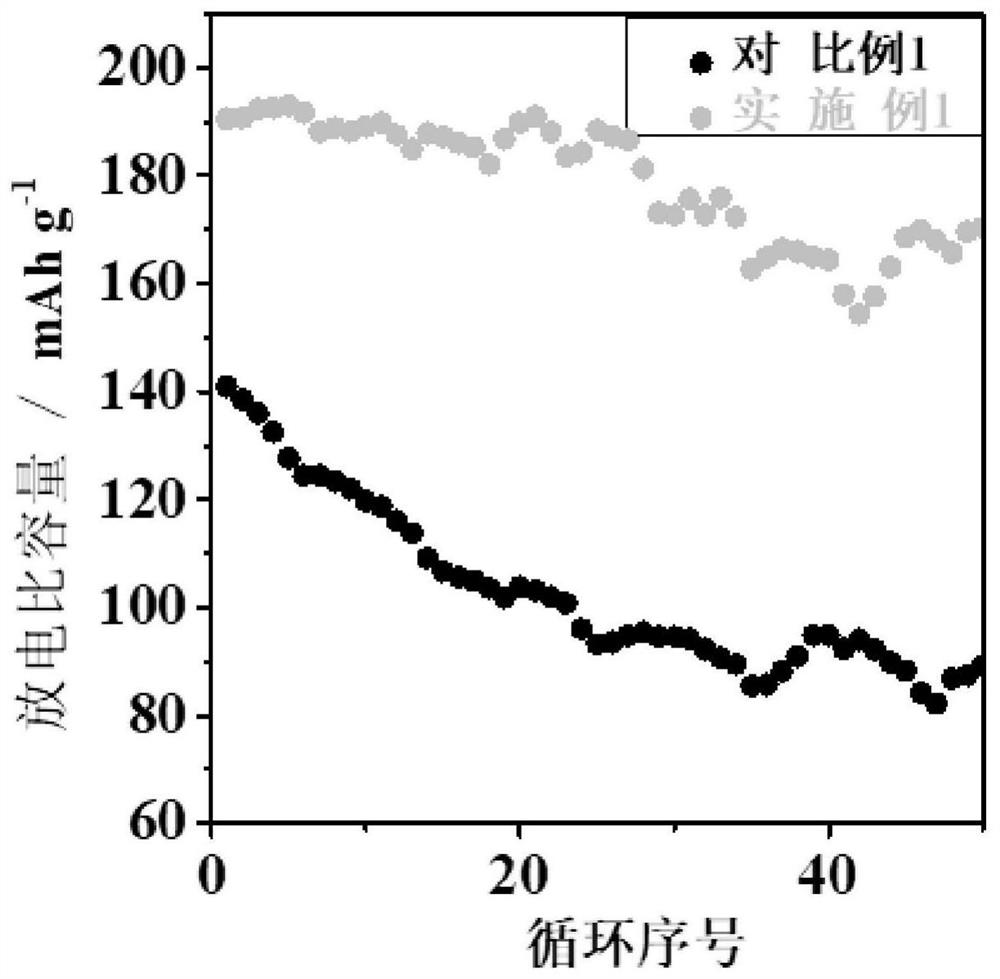

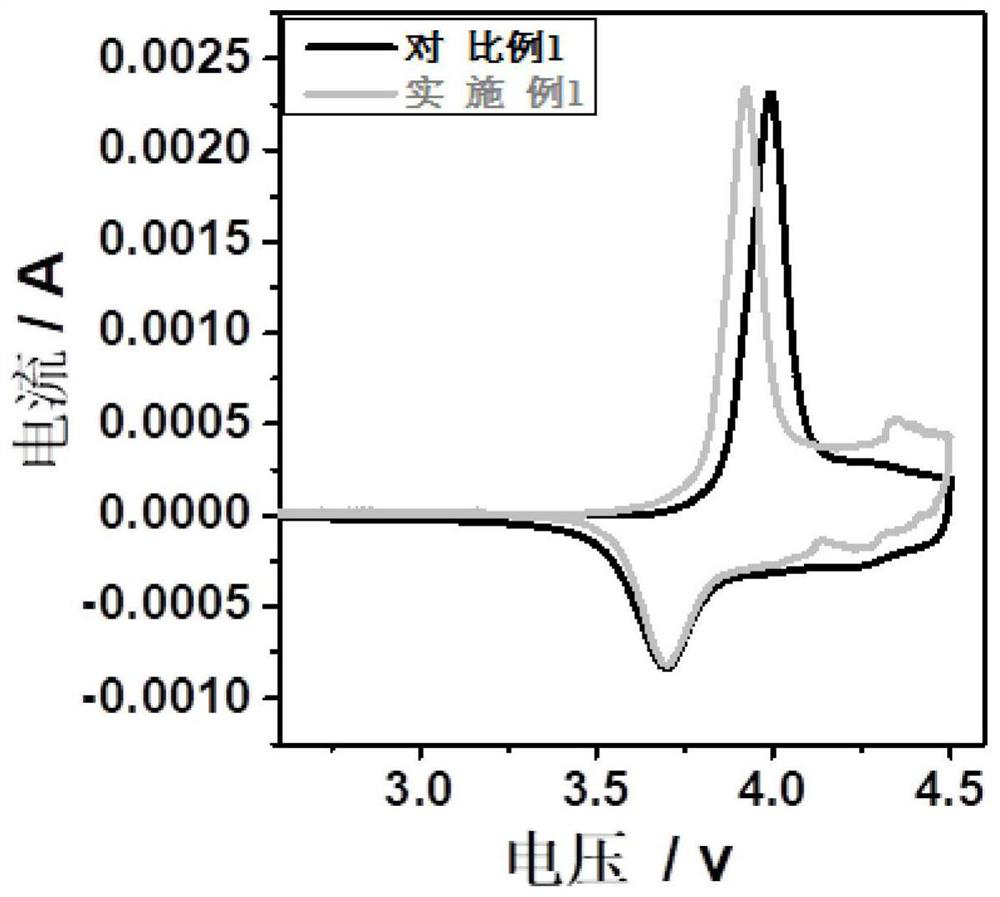

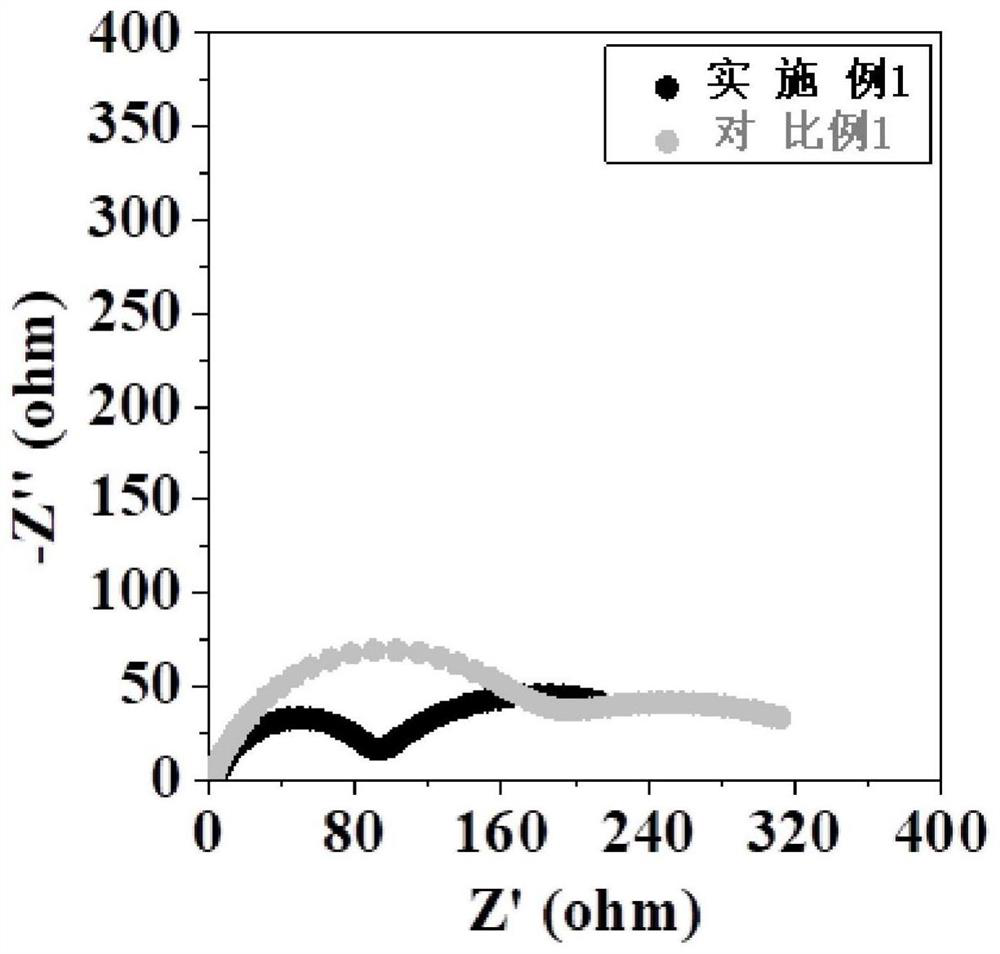

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of not being able to meet the application requirements of high-voltage lithium-ion batteries, the battery cycle performance is not good enough, and the degree of improvement is not enough, so as to reduce the generation of irreversible capacity and excellent Cycling performance, avoiding the effect of continuous contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A battery electrolyte, the preparation method is as follows:

[0041] (1) Ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate are mixed according to the mass ratio of 1:1:1 after dewatering by molecular sieve, and then LiPF is added 6 Dissolve and mix to make LiPF 6 The concentration is 1mol / L;

[0042] (2) Add functional additives to the solution obtained in step (1), and mix to obtain an electrolyte for batteries, wherein the functional additive has the following structure, and the amount added is 0.1% of the total mass of the electrolyte.

[0043]

Embodiment 2

[0045] A battery electrolyte, the preparation method is as follows:

[0046] (1) Mix ethylene carbonate, dimethyl carbonate, and diethyl carbonate in a mass ratio of 1:1:1 after dewatering with molecular sieves, and then add LiPF 6 Dissolve and mix to make LiPF 6 The concentration is 1.2mol / L;

[0047] (2) Add functional additives to the solution obtained in step (1), and mix to obtain an electrolyte for batteries, wherein the functional additives have the following structure, and the added amount is 0.02% of the total mass of the electrolyte.

[0048]

Embodiment 3

[0050] A battery electrolyte, the preparation method is as follows:

[0051] (1) Mix ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate with molecular sieve to remove water at a mass ratio of 1:1:1, and then add LiPF with a mass ratio of 9:1 6 and LiBF 4 Dissolving and mixing, so that the concentration of the inorganic lithium salt is 2mol / L;

[0052] (2) Add a functional additive to the solution obtained in step (1), and mix to obtain an electrolyte for a battery, wherein the functional additive has the following structure, and the amount added is 1% of the total mass of the electrolyte.

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com