A kind of prolific gasoline catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of high energy consumption, cumbersome preparation process and high catalyst preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

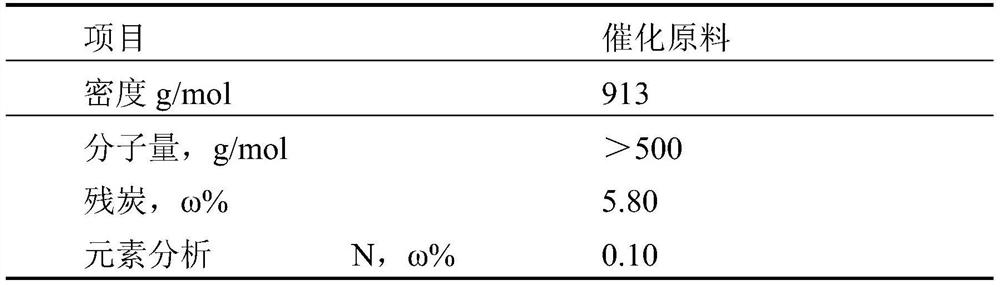

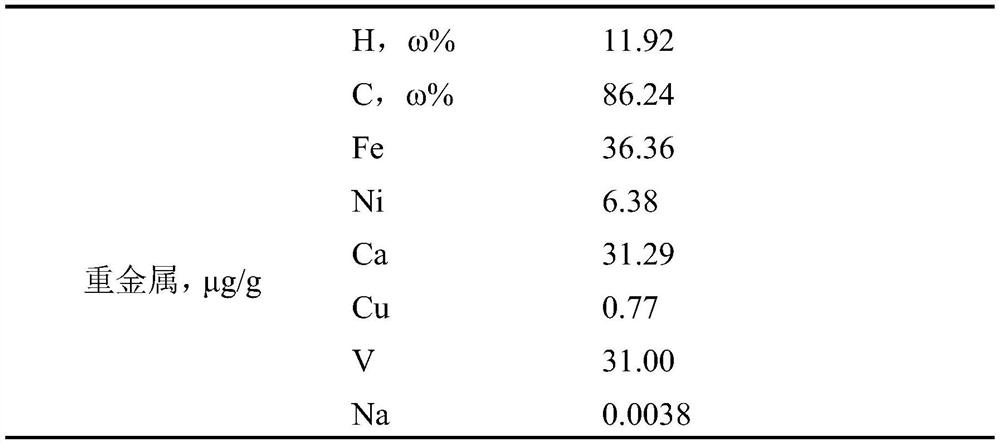

Image

Examples

Embodiment 1

[0041] (1) Preparation of the Y-type molecular sieve modified by phosphorus and magnesium: get 922 grams of rare earth ultra-stable Y (dry basis), after beating with 1956 grams of deionized water, add 9.2 grams of diammonium hydrogen phosphate (in terms of phosphorus), and react 2 hours, then 7.1 g of magnesium chloride (calculated as magnesium) was added to the above slurry for mixing and beating, and reacted at 95° C. for 1 hour to obtain phosphorus and magnesium modified molecular sieve Y1.

[0042] (2) Preparation of modified matrix material: 872 grams of kaolin, 560 grams of halloysite, 976 grams of aluminum sol, 1056 grams of pseudoboehmite and 3257 grams of deionized water were mixed and beaten, stirred for 30 minutes, and 10 grams of phosphoric acid was added (calculated as phosphorus), and stirred evenly to prepare the modified matrix material M1.

[0043] The above phosphorus and magnesium modified molecular sieve Y1 and modified matrix material M1 were mixed and bea...

Embodiment 2

[0045] (1) Preparation of Y-type molecular sieve modified by phosphorus and magnesium: get 1210 grams of rare earth Y (dry basis), after beating with 6200 grams of deionized water, add 1.3 grams of phosphoric acid (calculated as phosphorus), react for 1 hour, and then add to the above-mentioned Add 61 grams of magnesium nitrate (calculated as magnesium) to the slurry for mixing and beating, and react at 110° C. for 0.5 hour to obtain phosphorus and magnesium modified molecular sieve Y2.

[0046] (2) Preparation of modified matrix material: 150 grams of kaolin, 62 grams of aluminum sol, 160 grams of rare earth solution, 83 mL of hydrochloric acid, 607 grams of pseudoboehmite and 2000 grams of deionized water were mixed and beaten, stirred for 20 minutes, and 1 gram of Phosphoric acid (calculated as phosphorus), stirred evenly to prepare the modified matrix material M2.

[0047] The above-mentioned phosphorus and magnesium modified molecular sieve Y2 and modified matrix material...

Embodiment 3

[0049] (1) Preparation of the Y-type molecular sieve modified by phosphorus and magnesium: get 516 grams of hydrogen Y (dry basis) and 385 grams of ultra-stable Y (dry basis), after beating with 3308 grams of deionized water, add 2.3 grams of ammonium phosphate (with Phosphorus) and 2 grams of phosphoric acid (calculated as phosphorus), reacted for 3 hours, then added 0.7 gram of magnesium sulfate (calculated as magnesium) and 0.2 gram of magnesium chloride (calculated as magnesium) to the above slurry, mixed and beaten, and reacted at 60 ° C for 2 hours, phosphorus and magnesium modified molecular sieve Y3 was obtained.

[0050] (2) Preparation of modified matrix material: 1203 grams of kaolin, 121 grams of aluminum sol, 83 mL of hydrochloric acid, 176 grams of pseudoboehmite and 2000 grams of deionized water were mixed and beaten, stirred for 45 minutes, and 5 grams of diammonium hydrogen phosphate ( Calculated as phosphorus), and stirred evenly to prepare the modified matri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com