Preparation method of porous carbon based on polyaniline nanofiber

A nanofiber and polyaniline technology, applied in the field of nanomaterials, can solve the problems of reducing the active site of the material, the activity of the unused material, the agglomeration of carbon fibers, etc., and achieve the effect of increasing the ion conductivity, increasing the active site, and increasing the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

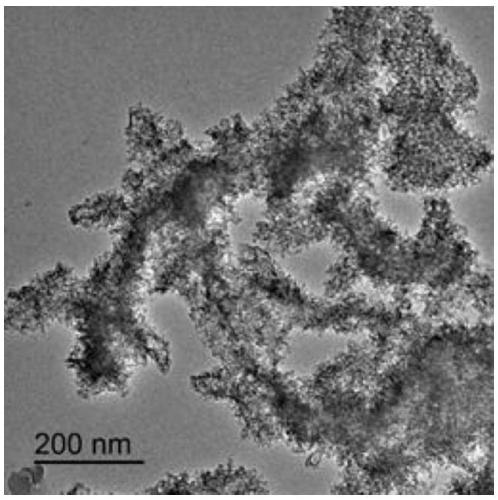

Embodiment 1

[0039] (1) SiO 2 / polyaniline (SiO 2 / PANI) fiber preparation

[0040] Add 0.921 mL of phytic acid and 2 mL of deionized water to the vial, then add 0.458 mL of aniline monomer and 0.05 mL of SiO 2 Ultrasound to mix evenly, weigh 0.286 g of ammonium persulfate and dissolve in 1 mL of deionized water, and cool the above two solutions to 0-5 o After mixing the reaction at C, keep the temperature unchanged for 12 h. Get SiO 2 / PANI product, the product was washed with deionized water to remove impurities, and dispersed in 9 mL of deionized water for later use.

[0041] (2) SiO 2 / Modification of PANI

[0042] Take the above 3 mL SiO 2 / PANI solution, add 12 mL of deionized water and 0.3 mL of ammonia water for ultrasonic dispersion, centrifuge to discard the supernatant, and add to the wet SiO 2 Add 20 mL of deionized water to PANI and stir for 12 h. The supernatant was discarded by centrifugation, and washed twice with water.

[0043] (3) SiO 2 / PANI / SiO 2 material s...

Embodiment 2

[0050] (1) SiO 2 / polyaniline (SiO 2 / PANI) fiber preparation

[0051] Add 0.921 mL of phytic acid and 2 mL of deionized water to the vial, then add 0.458 mL of aniline monomer and 0.1 mL of SiO 2 Ultrasound to mix evenly, weigh 0.286 g of ammonium persulfate and dissolve in 1 mL of deionized water, and cool the above two solutions to 0-5 o After mixing the reaction at C, keep the temperature unchanged for 12 h. Get SiO 2 / PANI product, the product was washed with deionized water for impurities, and dispersed in 9 mL of deionized water for later use.

[0052] (2) SiO 2 / Modification of PANI

[0053] Same as the method of Example 1.

[0054] (3) SiO 2 / PANI / SiO 2 material synthesis

[0055] Same as the method of Example 1.

[0056] (4) Synthesis of porous carbonized polyaniline nanofibers and template SiO 2 remove

[0057] Same as the method of Example 1.

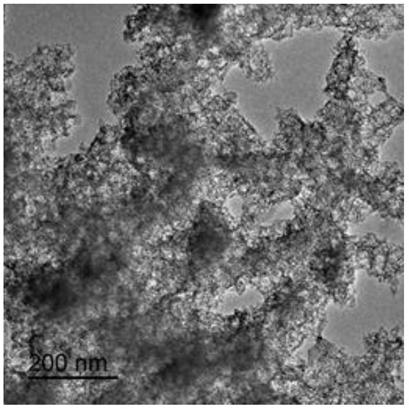

[0058] Such as figure 2 The TEM morphology characteristic map shown can be seen: the obtained porous carbo...

Embodiment 3

[0060] (1) SiO 2 / polyaniline (SiO 2 / PANI) fiber preparation

[0061] Add 0.921 mL of phytic acid and 2 mL of deionized water to the vial, then add 0.458 mL of aniline monomer and 0.2 mL of SiO 2 Ultrasound to mix evenly, weigh 0.286 g of ammonium persulfate and dissolve in 1 mL of deionized water, and cool the above two solutions to 0-5 o After mixing the reaction at C, keep the temperature unchanged for 12 h. Get SiO 2 / PANI product, the product was washed with deionized water for impurities, and dispersed in 9 mL of deionized water for later use.

[0062] (2) SiO 2 / Modification of PANI

[0063] Same as the method of Example 1.

[0064] (3) SiO 2 / PANI / SiO 2 material synthesis

[0065] Same as the method of Example 1.

[0066] (4) Synthesis of porous carbonized polyaniline nanofibers and template SiO 2 remove

[0067] Same as the method of Example 1.

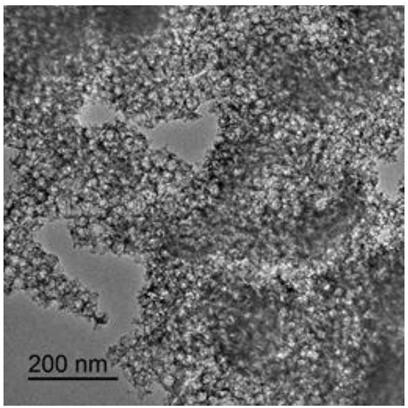

[0068] Such as image 3 The TEM morphology characteristic map shown can be seen: the obtained porous carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com