Method for removing arsenic and recovering valuable metal from ilmenite smoke dust

A valuable metal, ilmenite technology, applied in the field of comprehensive utilization of resources, can solve the problems of low efficiency and high processing cost, and achieve the effects of low cost, efficient recovery and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

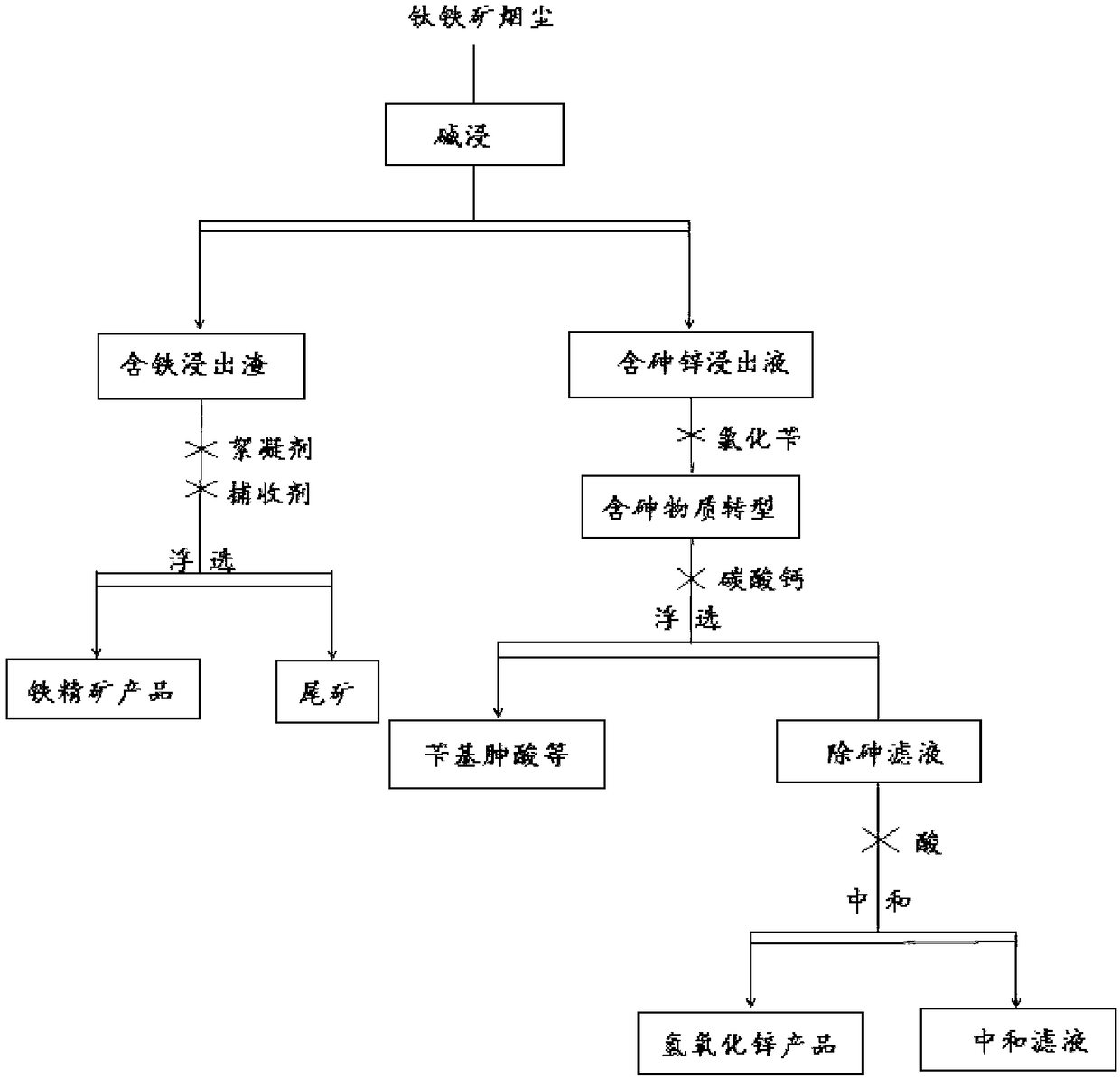

[0033] The above method is used to treat the ilmenite dust containing 6.077% of arsenic, 12.88% of zinc and 20.50% of iron. Put 600g of ilmenite soot into 3L of sodium hydroxide solution with a concentration of 18g / L for alkaline leaching, control the leaching temperature at 90°C, and leaching time for 1h, so that the arsenic oxides and zinc oxides in the ilmenite soot The compound is converted into arsenic salt and zinc salt and dissolved in the leach solution, and the solid and liquid are separated to obtain a leach solution containing arsenic salt and zinc salt, and a leach residue containing valuable metals such as iron; slowly add 70g of Benzyl chloride is subjected to arsenic conversion reaction, the temperature is controlled at 75°C, and the reaction time is 5h to obtain a sodium benzyl arsenic acid solution; the reacted solution is transferred to a flotation cell, and 500g / t calcium carbonate (-200~+400 Purpose) After fully reacting for 25 minutes, carry out flotation ...

Embodiment 2

[0043] The above method is used to treat the ilmenite dust containing 1.98% of arsenic, 20.33% of zinc and 32.12% of iron. Put 600g of ilmenite soot into 3L of water with a sodium hydroxide concentration of 6g / L for alkaline leaching, control the leaching temperature at 90°C, and leaching time for 2h, so that the arsenic oxide and zinc oxide compounds in the ilmenite soot Converted into arsenic salt and zinc salt, dissolved in the leach solution, filtered to obtain leach solution containing arsenic salt and zinc salt, and leach residue containing valuable metals such as iron; slowly add 25g of benzyl chloride with a mass fraction greater than 99.5% in the leach solution Carry out arsenic conversion reaction to obtain sodium benzyl arsenate solution, control the temperature at 75°C, and react for 5 hours; transfer the reacted solution into a flotation cell, and add 500g / t calcium carbonate (-200~+400 mesh) to fully After 30 minutes of reaction, carry out flotation, and collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com