Method for reclaiming au and regenerating etching solution from iodine series etching waste liquid

A technology of etching solution and electrolytic recovery, which is applied in the direction of chemical instruments and methods, instruments, electrolytic components, etc., can solve the problems of difficult regeneration of etching solution, reduction of iodine ion concentration, and reduction of etching ability, so as to inhibit the precipitation of electrolysis and iodine, Stable and efficient regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

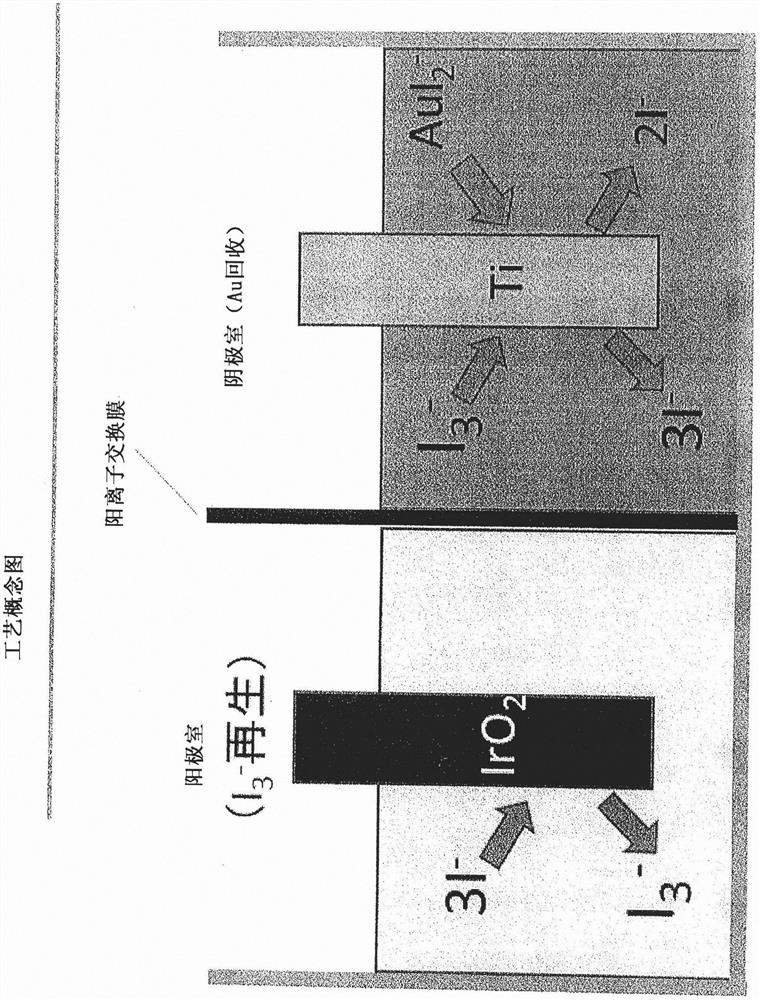

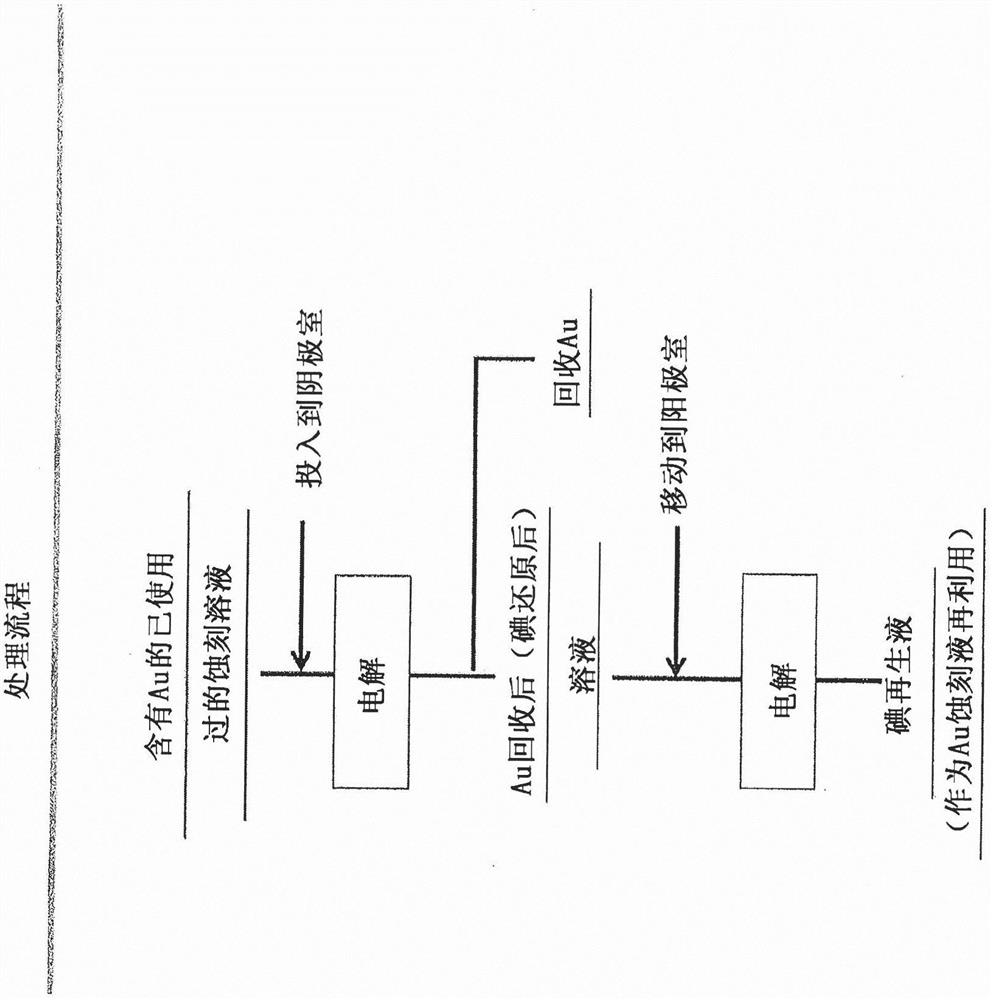

[0031] In the electrolytic cell in which the cathode chamber and the anode chamber were separated by a cation exchange membrane, 500 mL of an etching solution containing Au was supplied to the cathode chamber.

[0032] This Au-containing etching solution was composed of the following components. KI(0.25mol / L)+I 2 (0.14mol / L)+Au(0.03mol / L)

[0033] On the other hand, 500 mL of the solution after recovery of Au (after iodine reduction) was supplied to the anode chamber.

[0034] The solution after recovering Au (after iodine reduction) consisted of the following components.

[0035] KI (0.25mol / L)

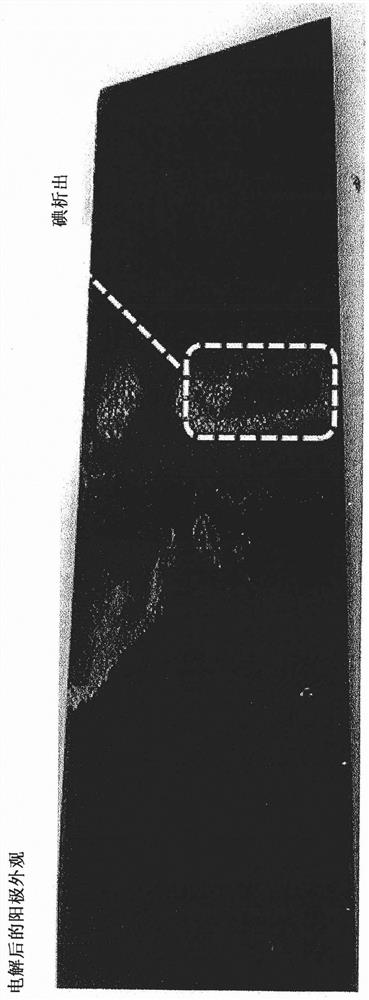

[0036] The cathode (counter electrode) uses Ti, and the anode (working electrode) uses IrO coated on Ti 2 material, set the reference electrode as Ag / AgCl. At this time, the impregnation area of the Ti electrode was set to 20 cm 2 , the IrO 2 The impregnation area of the electrode is set to 62cm 2 , and set the current density ratio of the cathode to the anode as 3.1. Th...

Embodiment 2

[0039] Set the impregnation area of the Ti electrode to 2 cm 2 , the IrO 2 The impregnation area of the electrode is set to 100cm 2 , and the current density ratio of the cathode and the anode was set to 50, and the electrolytic treatment was performed under the same conditions as in Example 1.

[0040] Through the above electrolytic treatment, the recovery rate of Au in the cathode chamber was 96.3%. In addition, the change of pH before and after electrolysis was investigated. As a result, in the anode chamber, the pH before electrolysis was 5.01, and it was 4.98 after electrolysis. In the cathode chamber, the pH before electrolysis was 5.11, and it was 5.13 after electrolysis. electrolysis. As a result of investigating the etching performance of the regenerated etching solution, it was confirmed that 12.31 g of Au (Au concentration: 5.73 g / L) was dissolved in the etching solution with a liquid volume of 2.15 L, and that it can be reused as an Au etching solution. use...

Embodiment 3

[0042] The electrolytic treatment was performed under the same conditions as in Example 1 except that the cathode potential was set at -0.95V.

[0043] Through the above electrolytic treatment, the recovery rate of Au in the cathode chamber was 96.1%. In addition, the change of pH before and after electrolysis was investigated. As a result, in the anode chamber, the pH before electrolysis was 4.99, and it was 4.31 after electrolysis. In the cathode chamber, the pH before electrolysis was 4.99, and it was 5.88 after electrolysis. electrolysis. As a result of investigating the etching performance of the regenerated etching solution, it was confirmed that 11.99 g of Au (Au concentration: 5.76 g / L) was dissolved in the etching solution with a liquid volume of 2.08 L, and that it can be reused as an Au etching solution. use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com