Preparation method and application of nickel-loaded SiO2@C core-shell material

A technology of supporting nickel and core-shell, applied in the field of catalysis, can solve the problems of inability to apply on a large scale, expensive precious metals, etc., and achieve the effects of simple and easy operation, high catalysis, and cheap and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A Ni-loaded SiO 2 The preparation method of @C core-shell material comprises the following steps:

[0040] Step 1. Silica microspheres with a particle size of about 200 nm were synthesized by the traditional Stöber method. The specific operation is: add 1 mL of deionized water, 22.05 mL of ethanol, and 29.45 mL of concentrated ammonia solution in a beaker, stir at room temperature for 20 min, then add 5 mL of TEOS (tetraethyl orthosilicate) dropwise, and stir the milky white mixed solution at room temperature After 6 h, the white product was washed 3 times with ethanol by centrifugation, then placed at 60°C, dried in vacuum for 12 h, and set aside;

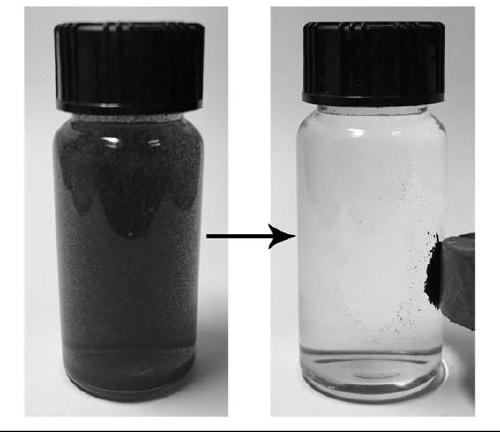

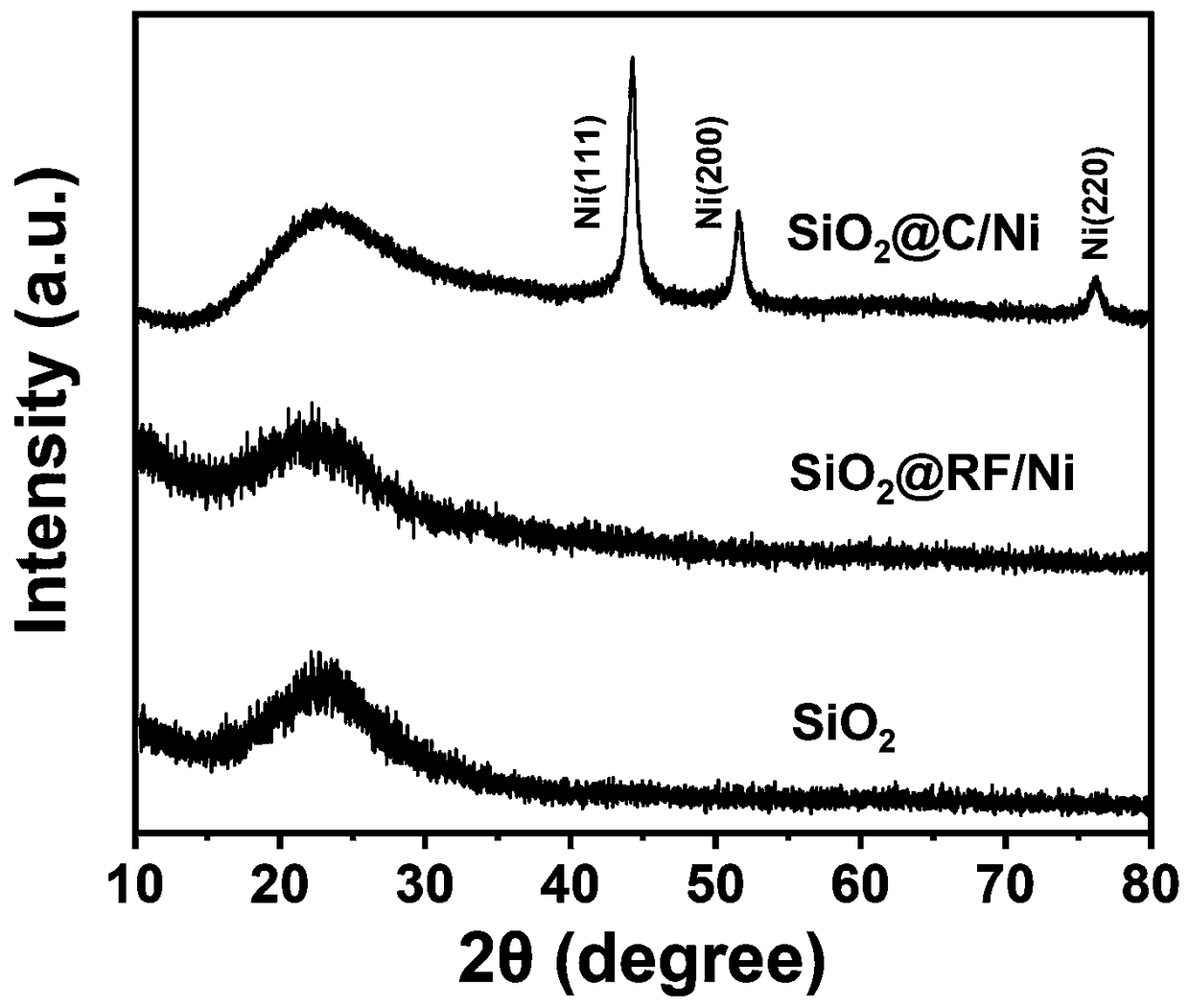

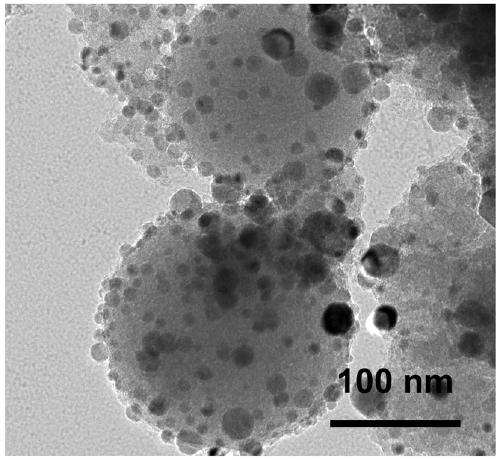

[0041] Step 2. Preparation of SiO by in situ polymerization 2 @RF / Ni. First, 0.2 g of SiO synthesized in step 1 2 Microspheres were ultrasonically dispersed in a mixture containing 17.6 mL of ethanol and 44 mL of water, 1.5 mmol of nickel acetate, 1.4 g of CTAB (cetyltrimethylammonium bromide), 0.22 g of resorcinol and ...

Embodiment 2

[0044] A kind of SiO loaded nickel in the present embodiment 2 The preparation method of @C core-shell material is the same as that of Example 1, the difference is,

[0045] The amount of nickel acetate added in step 2 is 0.5 mmol. Catalyst SCN-1 was obtained.

Embodiment 3

[0047] A kind of SiO loaded nickel in the present embodiment 2 The preparation method of @C core-shell material is the same as that of Example 1, the difference is,

[0048] The amount of nickel acetate added in step 2 was 1.0 mmol. Catalyst SCN-2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com