A ternary z-type composite acoustic catalyst for degrading antibiotic wastewater, its preparation method and application

A technology of antibiotic wastewater and composite sound, which is applied in the field of sound catalysis, can solve problems such as photocatalysis cannot be effectively solved, and achieve the effects of stable properties, broad prospects, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

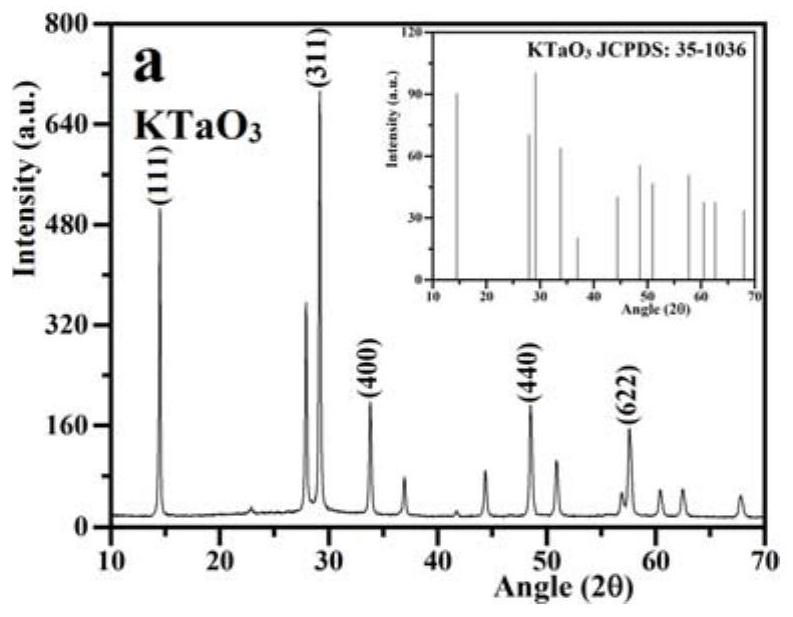

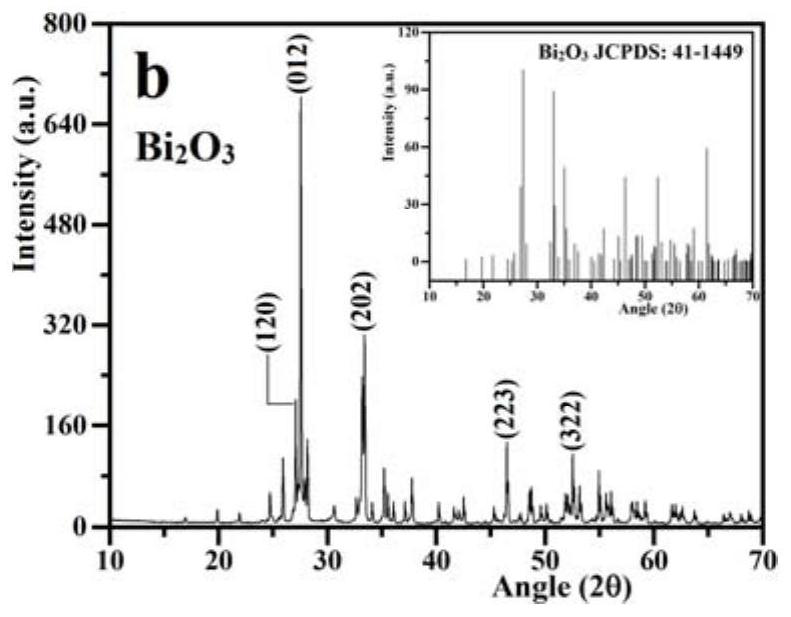

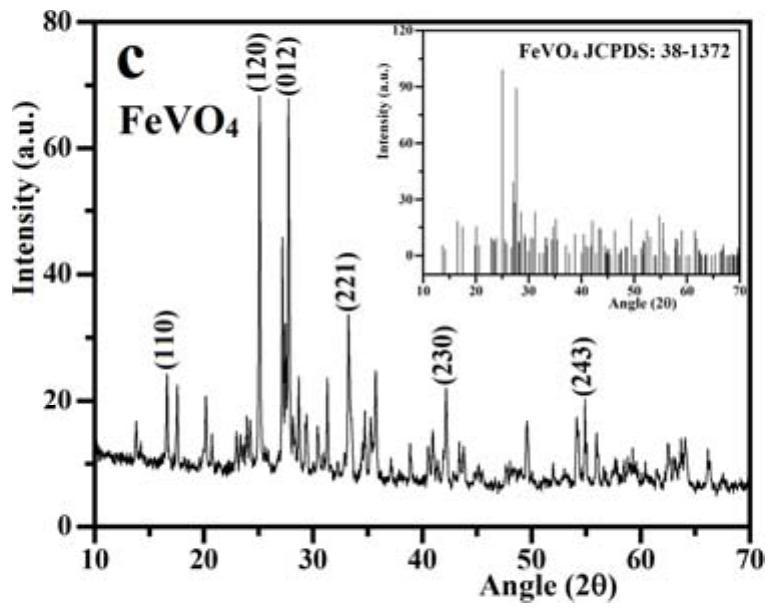

[0040] Example 1 A ternary Z-type composite acoustic catalyst KTaO 3 / FeVO 4 / Bi 2 o 3

[0041] (1) Preparation method

[0042] 1. Preparation of KTaO 3 powder

[0043] First, 4.40g of Ta 2 o 5 Add the powder into 30-50mL distilled water, and add KOH aqueous solution (11.20g KOH dissolved in 30mL distilled water) dropwise under magnetic stirring. Next, the resulting mixture was vigorously stirred for 3-6 h to obtain a white precipitate. The white precipitate was then transferred to an autoclave, which was sealed and heated at 180 °C for 24 h. After naturally cooling to room temperature, the resulting product was washed several times with distilled water and ethanol, and centrifuged to obtain a white solid. Dry the white solid at 80°C for 12h, then calcinate at 350°C for 2.0h, and grind to obtain KTaO 3 powder.

[0044] 2. Preparation of FeVO 4 powder

[0045] 8.10g of Fe(NO3 ) 3 9H 2 O was dissolved in 30-50 mL deionized water to form a transparent solution, an...

Embodiment 2 3

[0066] Example 2 Ternary Z-type composite acoustic catalyst KTaO 3 / FeVO 4 / Bi 2 o 3Application in degrading ceftriaxone sodium solution

[0067] (1) Effect of different ultrasonic irradiation time on sonocatalytic degradation

[0068] Experimental method: Take five Erlenmeyer flasks and mark them as (a):US, (b):US / KTaO 3 , (c): US / Bi 2 o 3 ,(d):US / KTaO 3 / Bi 2 o 3 and (e):US / KTaO 3 / FeVO 4 / Bi 2 o 3 , respectively put into 0.1g corresponding catalyst and 100mL 10.0mg / L ceftriaxone sodium aqueous solution in each Erlenmeyer flask. Simply ultrasonically irradiate the US bottle without adding any sonic catalyst. At a temperature of 25-28°C, with 300W, 40KHz ultrasonic irradiation, a certain amount of samples were taken out at 0min, 30min, 60min, 90min, 120min and 150min, and the degradation effect was detected using a UV-visible spectrometer.

[0069] The calculated degradation rate results are as follows Figure 7a shown. As expected, the degradation rates of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com