Preparation method for optical fiber preform

An optical fiber preform and manufacturing method technology, applied in the field of optical fiber manufacturing, can solve the problems of high fiber breaking rate and easy fiber breaking, and achieve the effects of high compressive strength, strong physical properties, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

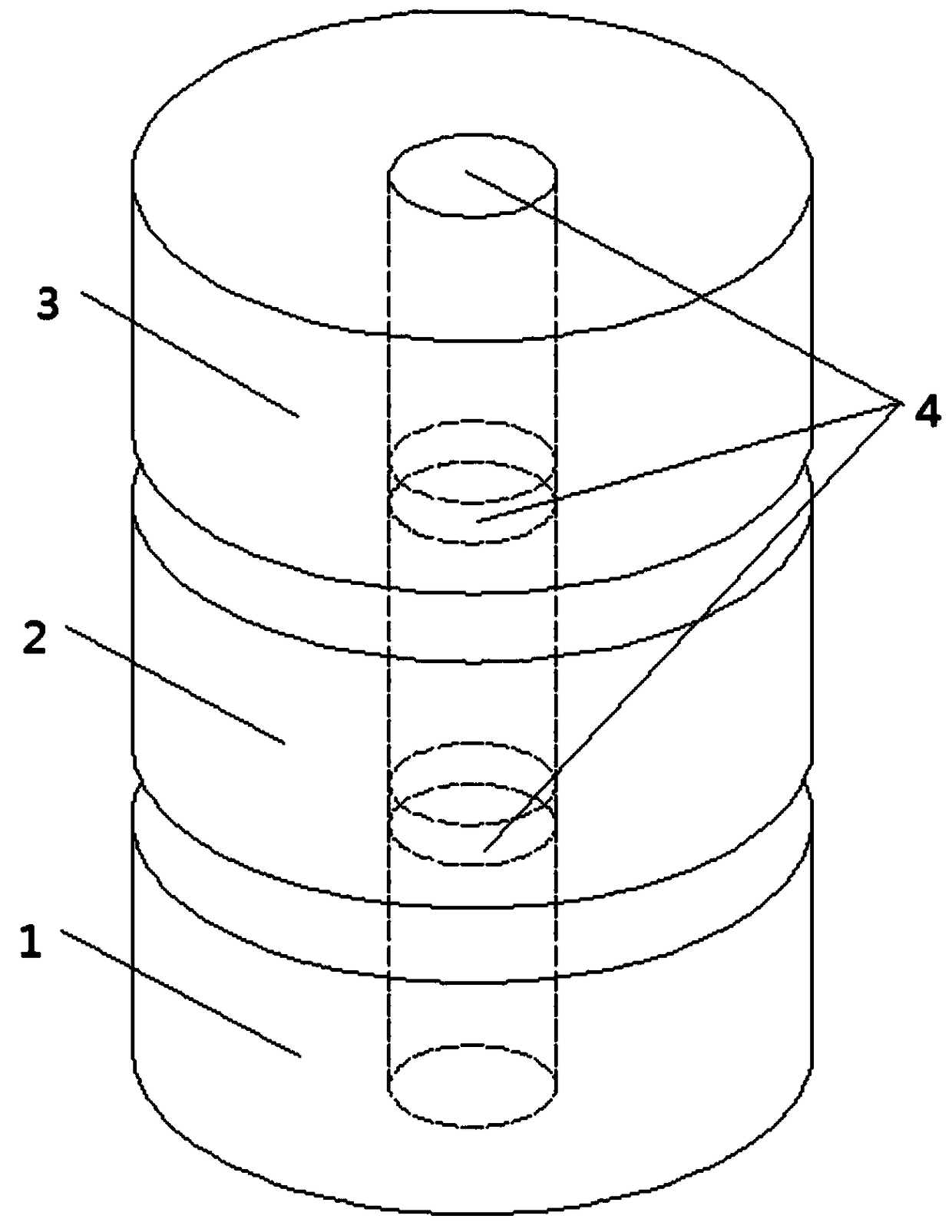

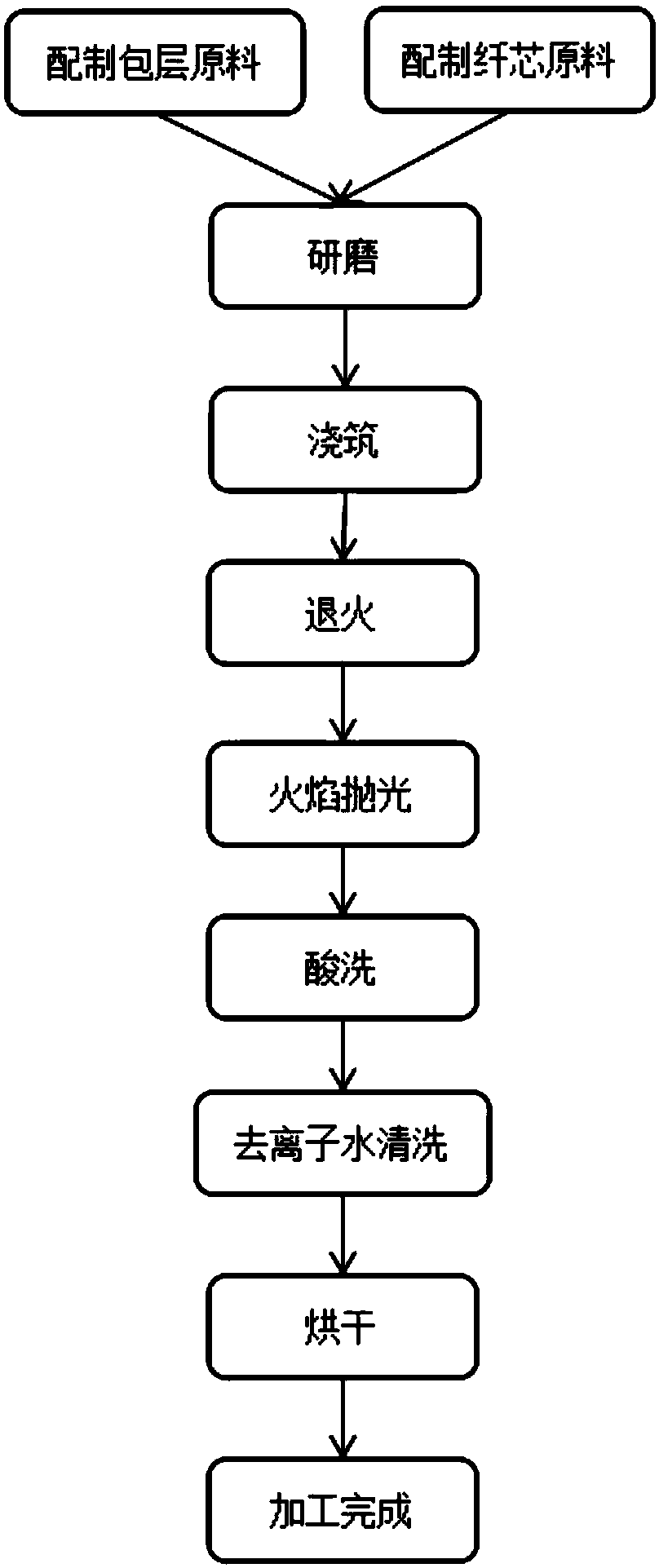

[0028] Such as figure 2Shown: a kind of manufacturing method of optical fiber preform, it is characterized in that making cladding and fiber core respectively, the step of described method is divided into: (1) prepare cladding group raw material and fiber core group raw material respectively; (2) make cladding group raw material and fiber core group raw material; Put the cladding and fiber core raw materials into the agate mortar and grind them evenly, put them in corundum crucibles with covers respectively, pour the cladding glass liquid into the preheated copper film after melting in the electric furnace, and pass it into the Protective gas, pouring to form a hollow glass tube; (3) Pour the core glass liquid into the cladding glass tube, and form an optical fiber preform after pouring; (4) Pass the poured optical fiber preform with the mold through the clamping Pull it into the electric furnace for annealing treatment. After the annealing is completed, close the electric fu...

Embodiment 2

[0034] Such as figure 2 Shown: a kind of manufacturing method of optical fiber preform, it is characterized in that making cladding and fiber core respectively, the step of described method is divided into: (1) prepare cladding group raw material and fiber core group raw material respectively; (2) make cladding group raw material and fiber core group raw material; Put the cladding and fiber core raw materials into the agate mortar and grind them evenly, put them in corundum crucibles with covers respectively, pour the cladding glass liquid into the preheated copper film after melting in the electric furnace, and pass it into the Protective gas, pouring to form a hollow glass tube; (3) Pour the core glass liquid into the cladding glass tube, and form an optical fiber preform after pouring; (4) Pass the poured optical fiber preform with the mold through the clamping Pull it into the electric furnace for annealing treatment. After the annealing is completed, close the electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com