A zirconia nozzle and its manufacturing method

A manufacturing method and technology of zirconia, applied in the field of refractory materials, can solve the problems of reduced life, brittle fracture, and decreased corrosion resistance, and achieve the effects of avoiding direct contact, increasing service life and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

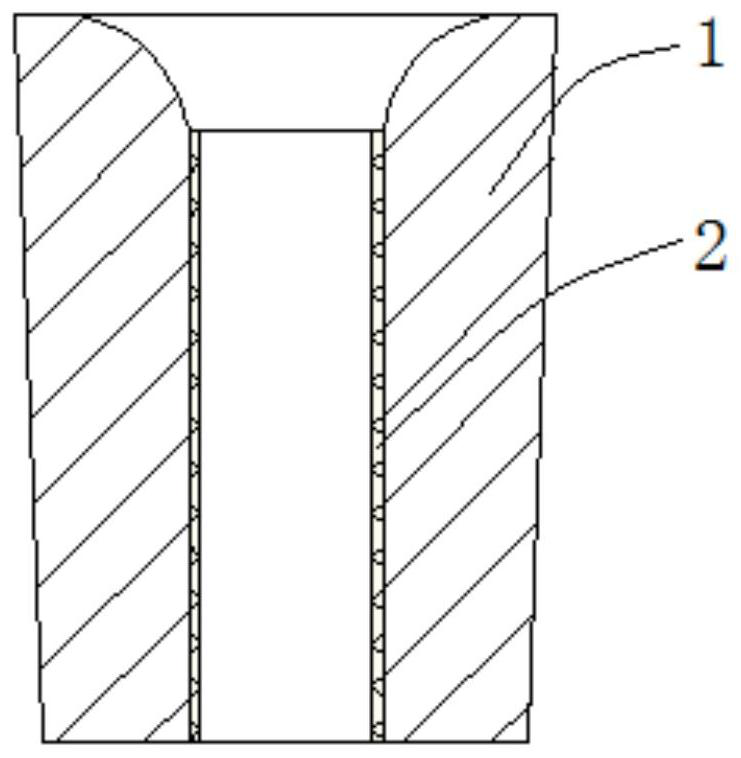

[0028] like figure 1 As shown, a zirconia moisture, the zirconia water, including a zirconia inner core 1, and an inner surface of the inner core 1 is provided with a layer of molten anti-brush composite material coating 2. The zirconia core density is 5.50 to 5.62 g / cm 3 The aerobic porosity is less than 3.8%. The thickness of the anti-brush composite coating is 0.5 mm to 5 mm. The molten anti-brush composite coating is gradually melted after the steel water is flushed, and the time in which it adheres to the thickness is preferably 4 to 15 minutes. By increasing the composite coating in the inner surface of high-density zirconia, the direct contact of the surface of the steel and the zirconia water is avoided, and the composite coating is slowly disappeared in the steel water brush. The zirconia on the water outlets for 5 minutes, avoiding the appearance of microcracks, no micro-cracking high-density zirconia on the hydrogeneous moratorium resistance is very good, and the serv...

Embodiment 2

[0030] like figure 1 As shown, a zirconia moisture, the zirconia water, including a zirconia inner core 1, and an inner surface of the inner core 1 is provided with a layer of molten anti-brush composite material coating 2. The raw material and mass percentage of the coating of the anti-brush composite material are: molten stone, 90%, silicone ash, 5% calcium aluminate cement. Among them, the zirconia-core density is 5.50 to 5.62 g / cm. 3 The aerobic porosity is less than 3.8%. The thickness of the impurities composite coating is 2 mm. The melting anti-brush composite material is coated, gradually melted after the steel water, and it has insisted for about 5 minutes. By increasing the composite coating in the surface of the hydroges in high-density zirconia, the direct contact of the surface of the steel water and the inner surface of the zirconia water is avoided, and the composite coating is slowly disappeared within 5 minutes in the steel water brush, thus being zirconia. Wate...

Embodiment 3

[0032] like figure 1 As shown, a zirconia moisture, the zirconia water, including a zirconia inner core 1, and an inner surface of the inner core 1 is provided with a layer of molten anti-brush composite material coating 2. The material and mass percentage of the coating of the anti-brush composite coating is: molten stone, 90%, silicone ash, 4% calcium aluminate cement. Among them, the zirconia-core density is 5.50 to 5.62 g / cm. 3 The aerobic porosity is less than 3.8%. The thickness of the impurities composite coating is 2.5 mm. The molten anti-brush composite material is coated, and gradually melted after the steel water is scored, and its persistence is about 6 minutes. By increasing the composite coating in the inner surface of high-density zirconia, the direct contact of the surface of the steel water and the inner surface of the zirconia water is avoided, and the composite coating is slowly disappeared within 6 minutes in the steel water brush, thus being zirconia Water m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com