Method for recycling waste thermosetting resin by utilizing microwave

A thermosetting and microwave heating technology, applied in separation methods, plastic recycling, recycling technology, etc., can solve problems such as difficult to popularize and apply, harsh recycling conditions, and low added value of recycled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

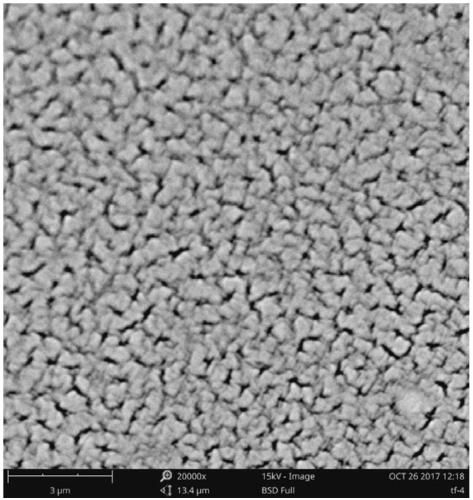

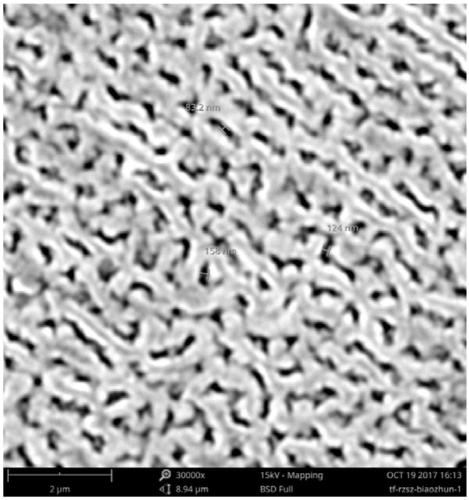

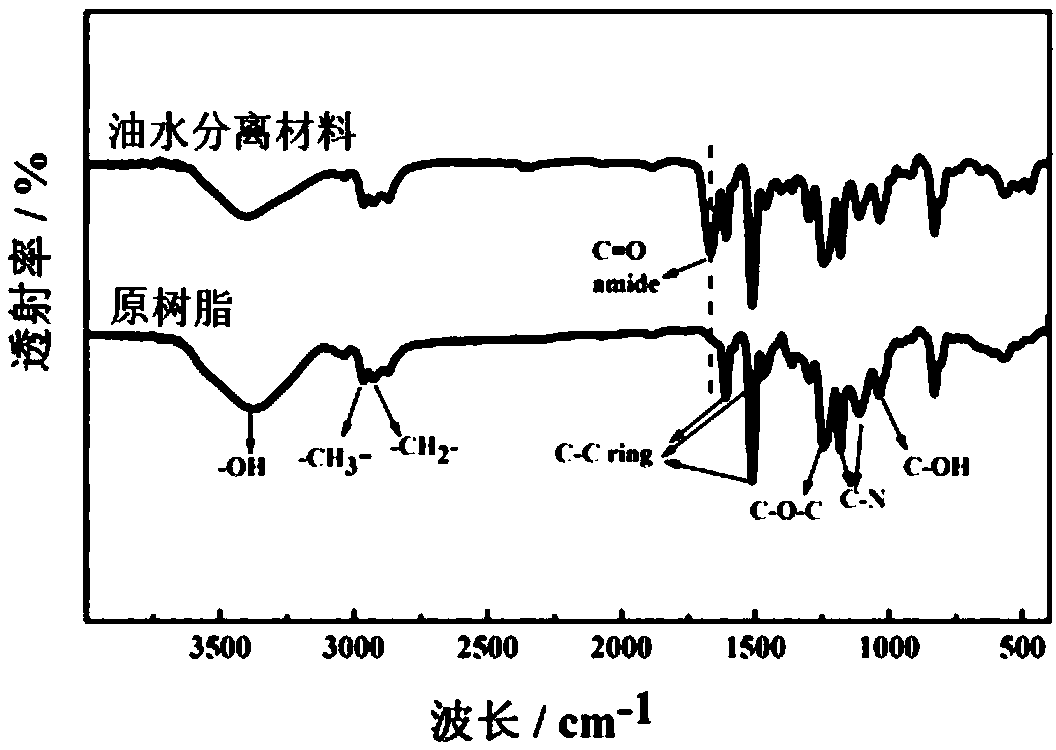

[0051] (1) Immerse 100 parts of waste unsaturated polyester resin in 100 parts of cyclohexanone, then place it in a frequency conversion microwave reactor, add a reflux device, and heat the resin for 120 minutes by microwave to fully swell the resin. Set the temperature of microwave heating to 120 ℃, during the microwave heating process, the microwave power is automatically adjusted within the range of no more than 500W with the reaction temperature, and the swollen resin is separated by filtration and washed with acetone under ultrasonic conditions to remove cyclohexanone, and the filtered cyclohexanone is directly recycled .

[0052] (2) The swollen and washed resin was microwave-heated for 7 minutes under the condition of microwave power of 500 W, that is, the recovery of waste unsaturated polyester resin was completed, and an oil-water separation material was obtained.

Embodiment 2

[0054](1) Immerse 100 parts of waste epoxy resin in 50 parts of N-methylpyrrolidone, then place it in a frequency conversion microwave reactor, add a reflux device, and heat it with microwave for 420 minutes to fully swell the resin. Set the microwave heating temperature to 60°C , during the microwave heating process, the microwave power is automatically adjusted within the range of no more than 800W with the reaction temperature, the swollen resin is separated by filtration and washed with ethyl acetate under ultrasonic conditions to remove N-methylpyrrolidone, and the filtered N-methylpyrrolidone The base pyrrolidone can be recycled directly.

[0055] (2) Microwave the swollen and washed resin for 15 minutes under the condition of microwave power of 200 W, that is, the recovery of waste epoxy resin is completed, and an oil-water separation material is obtained.

Embodiment 3

[0057] (1) Immerse 100 parts of waste furan resin in 200 parts of o-chlorotoluene, then place it in a frequency conversion microwave reactor, add a reflux device, set the microwave heating temperature to 100°C, and heat the resin for 300 minutes to fully swell the resin. During the process, the microwave power is automatically adjusted within the range of no more than 400W with the reaction temperature, and the swollen resin is filtered and separated, washed with ethanol under ultrasonic conditions to remove o-chlorotoluene, and the filtered o-chlorotoluene is directly recycled.

[0058] (2) The swollen and washed resin was microwave-heated for 2 minutes under the condition of microwave power of 400 W, that is, the recovery of waste furan resin was completed, and an oil-water separation material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com