Preparation method and product of fish skin gelatin

A technology for fish skin gelatin and fish skin is applied in the preparation of animal glue or gelatin, animal protein processing and other directions, which can solve the problems of environmental pollution, covalent bond breakage, complicated steps, etc., achieves low equipment requirements, reduces environmental pressure, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

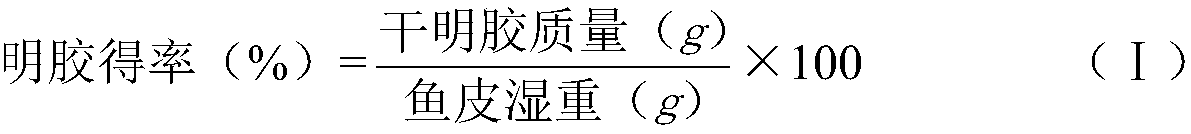

[0029] Prepare Fish Skin Gelatin

[0030] (1) Pre-treatment: 25g of fish skin is cleaned and descaled, and the epidermal fat is scraped off, then cut into small pieces of 4×4mm for later use;

[0031] (2) Degreasing: according to the ratio of material to liquid 1:2, the fish skin treated in step (1) is added into the aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 0.75%. Ultrasound for 1.5h under the condition of 120W, the unit of solid-liquid ratio is g:mL;

[0032] (3) Cleaning and draining: the fish skin treated in step (2) is cleaned with deionized water to completely remove the residual sodium dodecylbenzene sulfonate on the fish skin;

[0033] (4) Microwave pretreatment: Add the fish skin treated in step (3) into water according to the ratio of solid to liquid at 1:6, and then treat it with microwaves for 15 minutes at a temperature of 55°C and a microwave power of 350W. The unit is g:mL;

[0034] (5) Liquid nitrogen quick freezing: adding l...

Embodiment 2

[0040] Prepare Fish Skin Gelatin

[0041] (1) Pre-treatment: 25g fish skin is cleaned and descaled, then scraped off the epidermal fat, and then cut into small pieces of 4×4mm for later use;

[0042] (2) Degreasing: Add the fish skin treated in step (1) into the aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 1% according to the ratio of material to liquid at 1:3. Ultrasound for 2 hours under the condition of 180W, the unit of solid-liquid ratio is g:mL;

[0043] (3) Cleaning and draining: the fish skin treated in step (2) is cleaned with deionized water to completely remove the residual sodium dodecylbenzene sulfonate on the fish skin;

[0044] (4) Microwave pretreatment: Add the fish skin treated in step (3) into water according to the material-to-liquid ratio of 1:3, and then microwave it for 20 minutes at a temperature of 60°C and a microwave power of 370W. The unit is g:mL;

[0045] (5) Liquid nitrogen quick-freezing: adding liquid nitrogen t...

Embodiment 3

[0051] Prepare Fish Skin Gelatin

[0052] (1) Pre-treatment: 25g of fish skin is cleaned and descaled, and the epidermal fat is scraped off, then cut into small pieces of 4×4mm for later use;

[0053] (2) Degreasing: add the fish skin treated in step (1) into the aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 1.25% according to the ratio of material to liquid at 1:2.5. Ultrasound for 1.5h under the condition of 260W, the unit of solid-liquid ratio is g:mL;

[0054] (3) Cleaning and draining: the fish skin treated in step (2) is cleaned with deionized water to completely remove the residual sodium dodecylbenzene sulfonate on the fish skin;

[0055] (4) Microwave pretreatment: Add the fish skin treated in step (3) into water according to the ratio of solid to liquid at 1:5, and then treat it with microwave for 10 min at a temperature of 57°C and a microwave power of 400W. The unit is g:mL;

[0056] (5) Liquid nitrogen quick freezing: adding liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com