Method for extracting krill oil with high fatty acid content from antarctic krill

A technology of Antarctic krill and Antarctic krill powder, applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of incomplete solvent removal, high cost, low fatty acid content of Antarctic krill oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

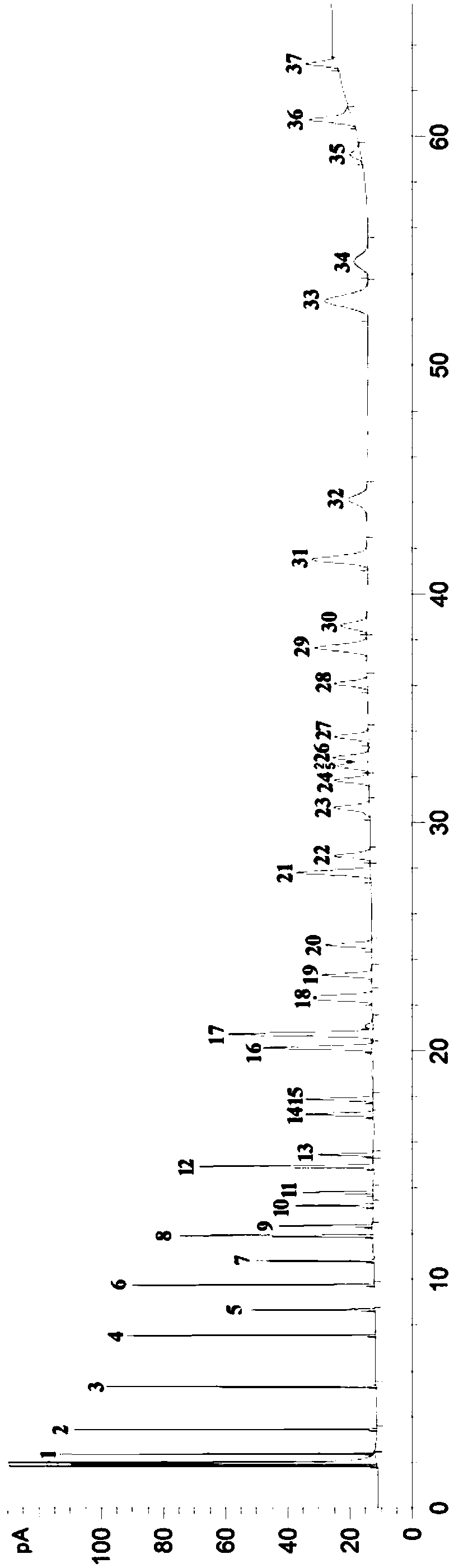

Image

Examples

Embodiment 1

[0033] (1) Take the frozen Antarctic krill raw material, put it in the refrigerator and thaw it away from light (4°C for 12 hours), after the thawing is complete, drain it; put the thawed Antarctic krill (moisture content 85%) in a vacuum freeze dryer- Under the condition of 45°C, freeze-dry overnight to control the water content within 7%; use a blade grinder to crush the dried shrimp to more than 60 mesh to obtain Antarctic krill powder;

[0034] (2) According to the solid-liquid volume ratio of Antarctic krill powder and organic solvent is 1:5, add organic solvent (ethanol:n-hexane=1:1) to leaching the Antarctic krill powder in step (1), vortex Spin for 10 minutes, centrifuge at a centrifugal rate of 4500r / min for 3-5 minutes, and take the supernatant;

[0035] (3) Continuously extract the supernatant liquid in step (2) three times, dry it with nitrogen and concentrate it to 10% of the stock solution, wash it three times with water to take the upper organic phase, and rotar...

Embodiment 2

[0037] (1) Take the frozen Antarctic krill raw material, put it in the refrigerator and thaw it away from light (4°C for 12 hours), after the thawing is complete, drain it; put the thawed Antarctic krill (moisture content 85%) in a vacuum freeze dryer- Under the condition of 45°C, freeze-dry overnight to control the water content within 7%; use a blade grinder to crush the dried shrimp to more than 60 mesh to obtain Antarctic krill powder;

[0038] (2) Take 3g of Antarctic krill powder from step (1) in a 50mL centrifuge tube, add 2mL of ethanol aqueous solution with a volume fraction of 95%, and mix well; ), and mix well; put the centrifuge tube in a water bath at 80°C for 40 minutes for hydrolysis;

[0039] (3) According to the solid-liquid volume ratio of Antarctic krill powder and organic solvent is 1:6, add organic solvent (ethanol:n-hexane=1:1) to the Antarctic krill powder after acid hydrolysis treatment in step (2) Extract, vortex for 8min, centrifuge at 4800r / min for ...

Embodiment 3

[0042] (1) Take the frozen Antarctic krill raw material, put it in the refrigerator and thaw it away from light (4°C for 12 hours), after the thawing is complete, drain it; put the thawed Antarctic krill (moisture content 85%) in a vacuum freeze dryer- Under the condition of 45°C, freeze-dry overnight to control the water content within 7%; use a blade grinder to crush the dried shrimp to more than 60 mesh to obtain Antarctic krill powder;

[0043] (2) Take 3g of Antarctic krill powder from step (1) in a 50mL centrifuge tube, add 2mL of ethanol aqueous solution with a volume fraction of 95%, and mix well; ), mix well; put the centrifuge tube in a water bath at 75°C for 45 minutes for hydrolysis;

[0044] (3) According to the solid-liquid volume ratio of Antarctic krill powder and organic solvent is 1:7, add organic solvent (ethanol:n-hexane=1:1) to Antarctic krill powder after acid hydrolysis treatment in step (2) For leaching, vortex for 8-12 minutes, centrifuge at 4000r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com