A kind of 20crmnti-based self-lubricating composite material with spherical structure ag-mg as solid lubricant and its preparation method

A solid lubricant and self-lubricating material technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of restricting further application, poor friction reduction and anti-wear performance, etc., to facilitate mass production, good friction reduction and wear resistance The effect of high performance and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

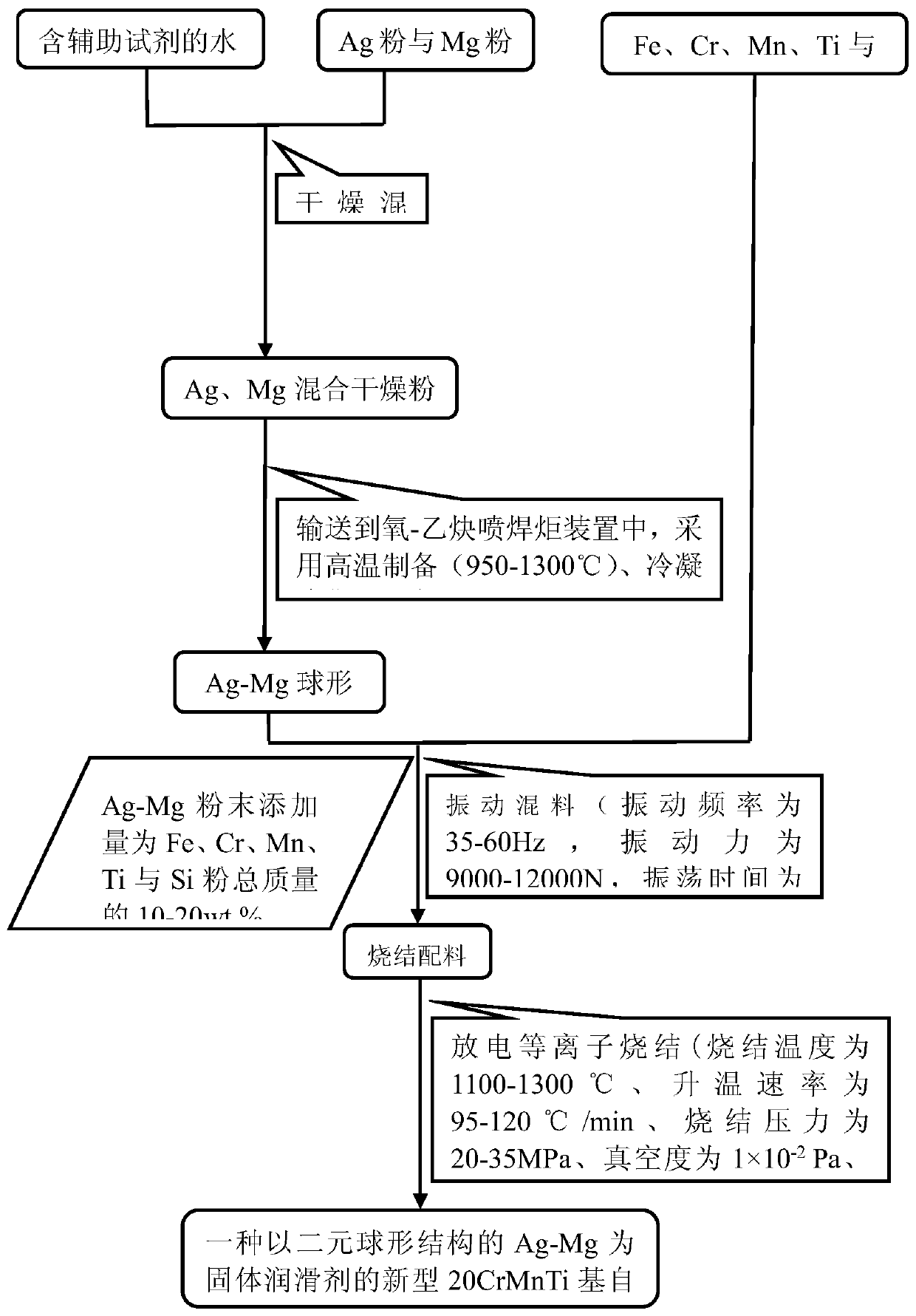

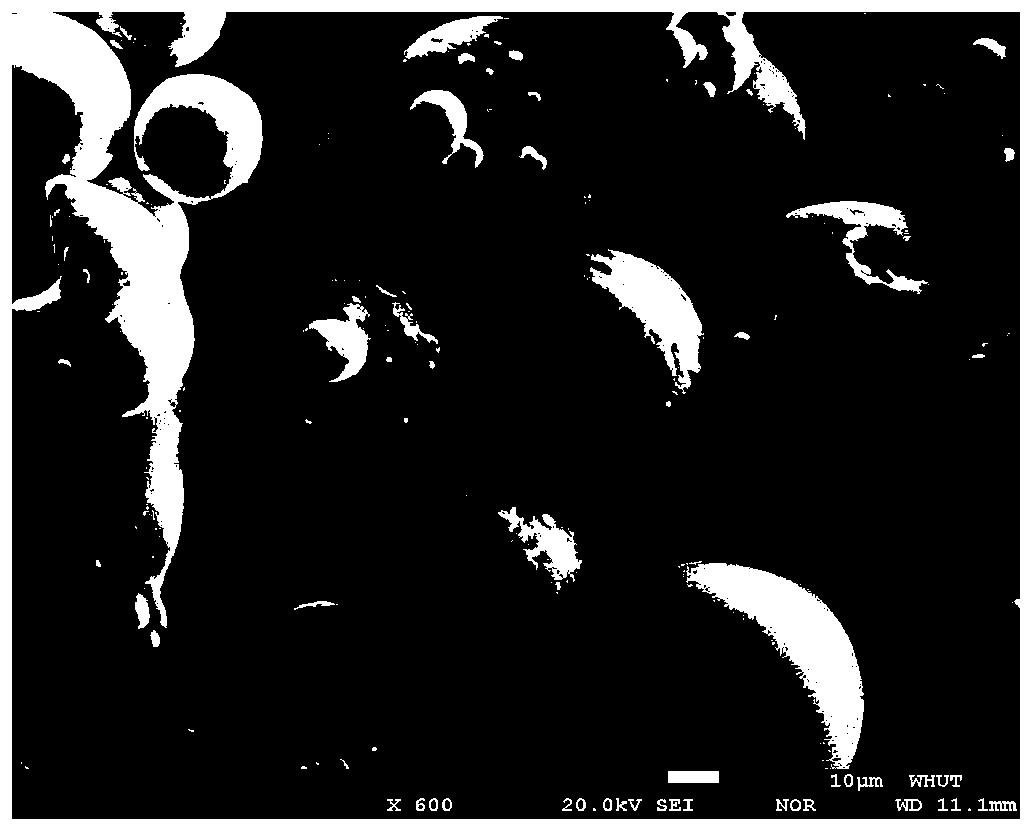

[0031]1) Preparation of binary spherical solid lubricant Ag-Mg: According to the atomic ratio (at.%) of about 52:48, select appropriate amount of Ag and Mg powders and add them to the aqueous solution containing auxiliary reagents, and stir evenly to form a uniformly distributed mixture liquid. After drying treatment, Ag and Mg are uniformly mixed powder particles. The dried powder particles are transported into the oxygen-acetylene spray torch device by the feeding device, and the molten droplet reactant is sprayed into the purified ultrapure water at a temperature of 950°C for condensation into balls. Collect the binary spherical solid lubricant Ag-Mg in ultrapure water, and dry it at ≤70°C to obtain the binary spherical solid lubricant Ag-Mg powder particles. The auxiliary reagent is a small amount of chlorinated sodium;

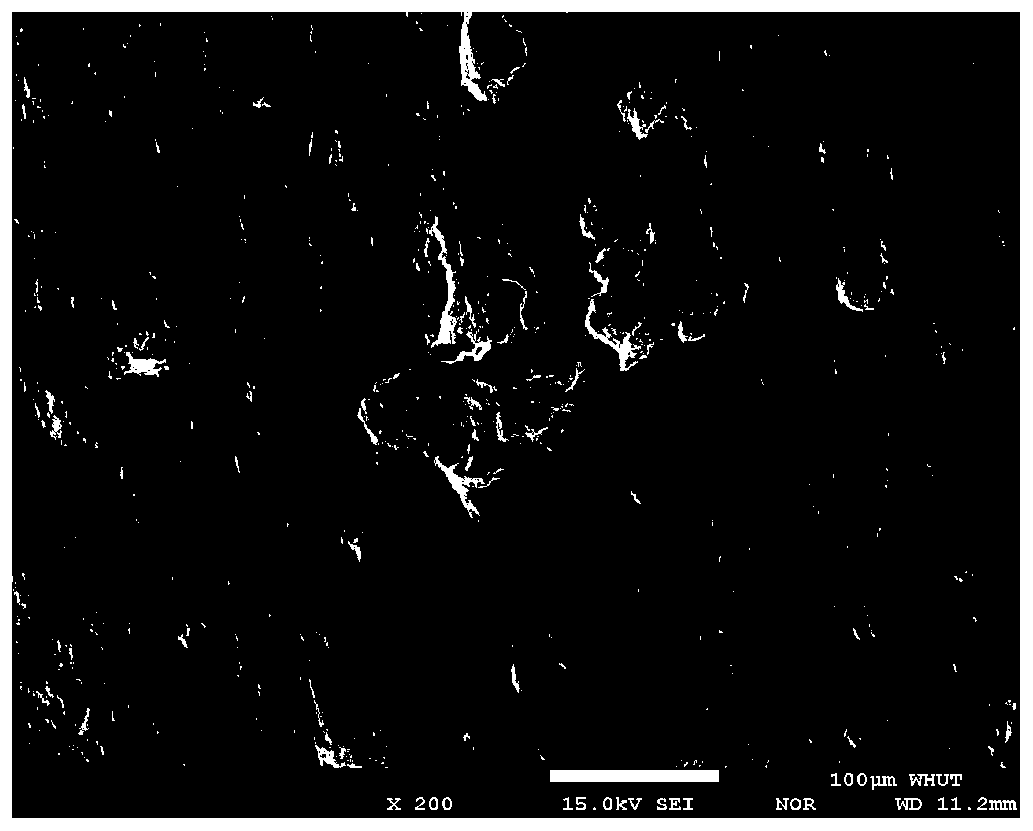

[0032] 2) Material ratio: 20CrMnTi matrix material is selected according to the mass ratio (wt.%) of Fe powder, Cr powder, Mn powder, Ti powder and Si ...

Embodiment 2

[0038] 1) Preparation of binary spherical solid lubricant Ag-Mg: According to the atomic ratio (at.%) of about 52:48, select appropriate amount of Ag and Mg powders and add them to the aqueous solution containing auxiliary reagents, and stir evenly to form a uniformly distributed mixture liquid. After drying treatment, Ag and Mg are uniformly mixed powder particles. The dried powder particles are transported into the oxygen-acetylene spray torch device by the feeding device, and the molten droplet reactant is sprayed into the purified ultrapure water at a temperature of 950°C for condensation into balls. Collect the binary spherical solid lubricant Ag-Mg in ultrapure water, and dry it at ≤70°C to obtain the binary spherical solid lubricant Ag-Mg powder particles;

[0039] 2) Material ratio: 20CrMnTi matrix material is selected according to the mass ratio (wt.%) of Fe powder, Cr powder, Mn powder, Ti powder and Si powder as 97.35:1.22:0.96:0.13:0.34. The solid lubricant Ag-Mg...

Embodiment 3

[0044] 1) Preparation of binary spherical solid lubricant Ag-Mg: According to the atomic ratio (at.%) of about 52:48, select appropriate amount of Ag and Mg powders and add them to the aqueous solution containing auxiliary reagents, and stir evenly to form a uniformly distributed mixture liquid. After drying treatment, Ag and Mg are uniformly mixed powder particles. The dried powder particles are transported into the oxygen-acetylene spray torch device by the feeding device, and the molten droplet reactant is sprayed into the purified ultrapure water at a temperature of 950°C for condensation into balls. Collect the binary spherical solid lubricant Ag-Mg in ultrapure water, and dry it at ≤70°C to obtain the binary spherical solid lubricant Ag-Mg powder particles;

[0045] 2) Material ratio: 20CrMnTi matrix material is selected according to the mass ratio (wt.%) of Fe powder, Cr powder, Mn powder, Ti powder and Si powder as 97.35:1.22:0.96:0.13:0.34. The solid lubricant Ag-Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com