Fully-mixed fermented feed as ration of beef cattle and preparation method of fully-mixed fermented feed

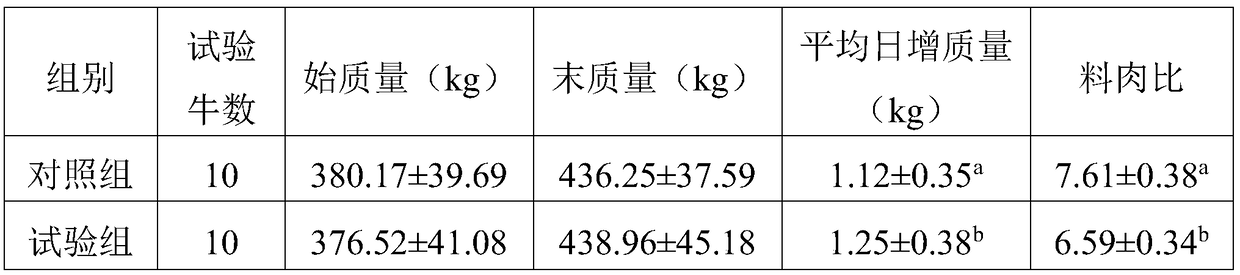

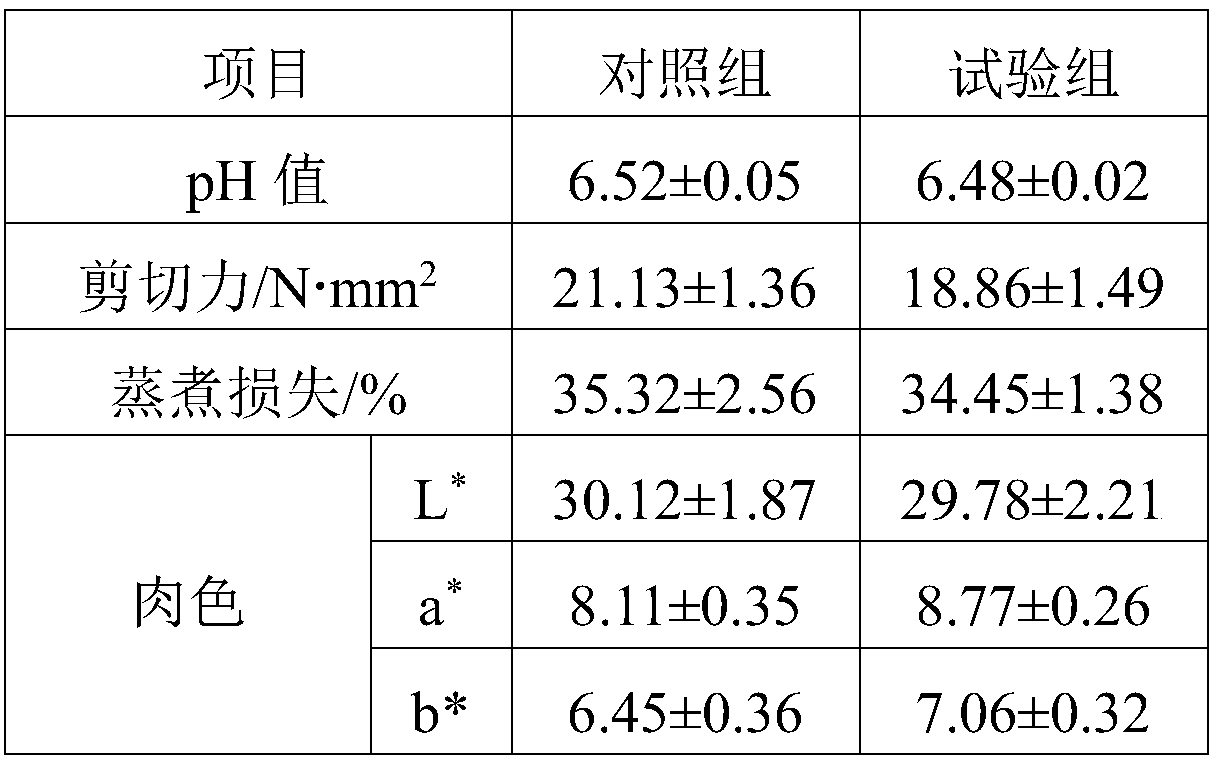

A fermented feed and full mixing technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of unsatisfactory income, poor nutritional balance and high feed cost for farmers, and achieve slaughter performance and meat quality improvement, The effect of improving nutritional value and palatability, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing fermented feed for beef cattle full mixed diet, comprising the following steps:

[0031] (1) Stevia slag is sieved to remove impurities; 5.5% vitamin premix, 22% trace element premix, 1.0% ethoxyquin and the remainder are rice husk powder to form a composite premix;

[0032] (2) Take 57 parts of stevia residue in (1), 1 part of compound premix, 22 parts of corn, 7 parts of rice bran, 8.6 parts of cottonseed protein, 0.9 part of calcium hydrogen phosphate, 0.6 part of stone powder, 1.0 part of baking soda, and table salt 0.6 parts, 0.8 parts of starter, and 0.5 parts of molasses were added to the mixer for mixing, and the water content of the raw materials was adjusted to 42% during the mixing process;

[0033] (3) After mixing the raw materials evenly, put them into a polyethylene film fermentation bag, seal the mouth of the bag and store it at room temperature. After 21 days of fermentation, it can be unsealed and fed.

Embodiment 2

[0035] A method for preparing fermented feed for beef cattle full mixed diet, comprising the following steps:

[0036] (1) Stevia slag is sieved to remove impurities; 4.0% vitamin premix, 17% trace element premix, 0.9% ethoxyquin and the remainder are rice husk powder to form a composite premix;

[0037] (2) Take 42 parts of stevia residue in (1), 1.2 parts of compound premix, 28 parts of corn, 14 parts of rice bran, 10.2 parts of cottonseed protein, 0.8 parts of calcium hydrogen phosphate, 0.7 parts of stone powder, 0.8 parts of baking soda, and salt 0.5 parts, 1.0 parts of starter, and 0.8 parts of molasses were added to the mixer for mixing, and the water content of the raw materials was adjusted to 38% during the mixing process;

[0038] (3) After mixing the raw materials evenly, put them into a polyethylene film fermentation bag, seal the mouth of the bag and store it at room temperature. After 28 days of fermentation, it can be opened and fed.

Embodiment 3

[0040] A method for preparing fermented feed for beef cattle full mixed diet, comprising the following steps:

[0041] (1) Stevia slag is sieved to remove impurities; 6.0% vitamin premix, 24% trace element premix, 1.2% ethoxyquin and the remainder are rice husk powder to form a composite premix;

[0042](2) Take 65 parts of stevia residue in (1), 1.2 parts of compound premix, 18 parts of corn, 4 parts of rice bran, 7.3 parts of cottonseed protein, 0.4 parts of calcium hydrogen phosphate, 0.6 parts of stone powder, 0.5 parts of baking soda, and table salt 0.5 parts, 1.2 parts of starter, and 1.5 parts of molasses are added to the mixer for mixing, and the water content of the raw materials is adjusted to 45% during the mixing process;

[0043] (3) After mixing the raw materials evenly, put them into polyethylene film fermentation bags, seal the bags and store them at room temperature. After 15 days of fermentation, they can be opened and fed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com