Flavor peptide and flavor peptide seasoning, and preparation method thereof

A technology for umami peptides and seasonings, which is applied in the field of umami peptides and umami peptide seasonings and their preparation, can solve the problems of single ingredients, soft umami taste, low nutritional value, etc., so as to improve the overall flavor. , the effect of high umami intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

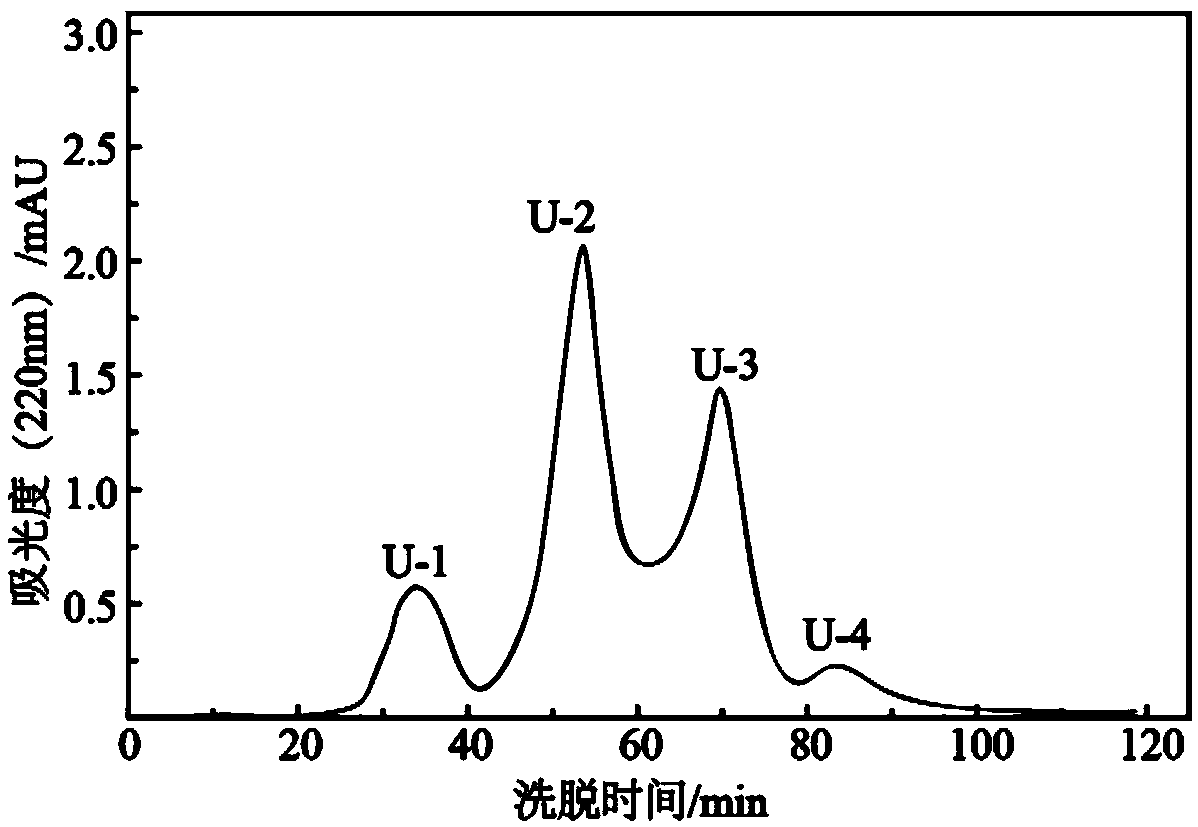

[0024] (1) Preparation of proteolysis solution: Nile tilapia provided by the Suifeng Breeding Farm in Shifang City, Deyang City was selected. It was dissected by professionals in the breeding base, deboned, and then transported back to the preparation base in cold chain. When preparing umami peptides, thaw the fish, grind it in a meat grinder and weigh it, then add ultrapure water twice the weight of the minced meat, and use a high-speed tissue masher to homogenize. Adjust the pH of the tilapia muscle homogenate to 7.0, add 0.05% papain and 0.02% neutral protease to the mass of the homogenate, mix well and put it in a water bath at 50°C for 20 hours for hydrolysis, then add the homogenate The flavor protease with a mass of 1.15% was hydrolyzed at 50°C for 4 hours. After the hydrolysis, the hydrolyzate was heated to 95°C, and the enzyme was inactivated for 15 minutes to obtain the enzymolyzate. Under the condition of 4°C, centrifuge the enzymatic hydrolyzate at a rate of 8000r...

Embodiment 2

[0032] Take by weighing Nile tilapia minced meat 100g in embodiment one, add 200mL ultrapure water, homogenate in the high-speed tissue masher, then add papain, 1.0% papain and 1.0% papain that account for homogenate quality 0.5% in the homogenate liquid Flavored protease, 0.05% trypsin and 0.01% neutral protease were mixed and stirred evenly, and the pH of the homogenate was adjusted to 6.0, and then placed in a water bath at 60°C for hydrolysis for 12 hours. After the hydrolysis, the hydrolyzate was heated to 90°C, and the enzyme was inactivated for 20 minutes to obtain the enzymolyzate. At 4°C, centrifuge the enzymatic hydrolyzate at a rate of 7000rmp for 25min, continue to extract the precipitate with ultra-pure water homogenate and centrifuge, combine the supernatant to obtain Nile tilapia protease hydrolyzate, and store it in a -80°C ultra-low temperature refrigerator Store for later use.

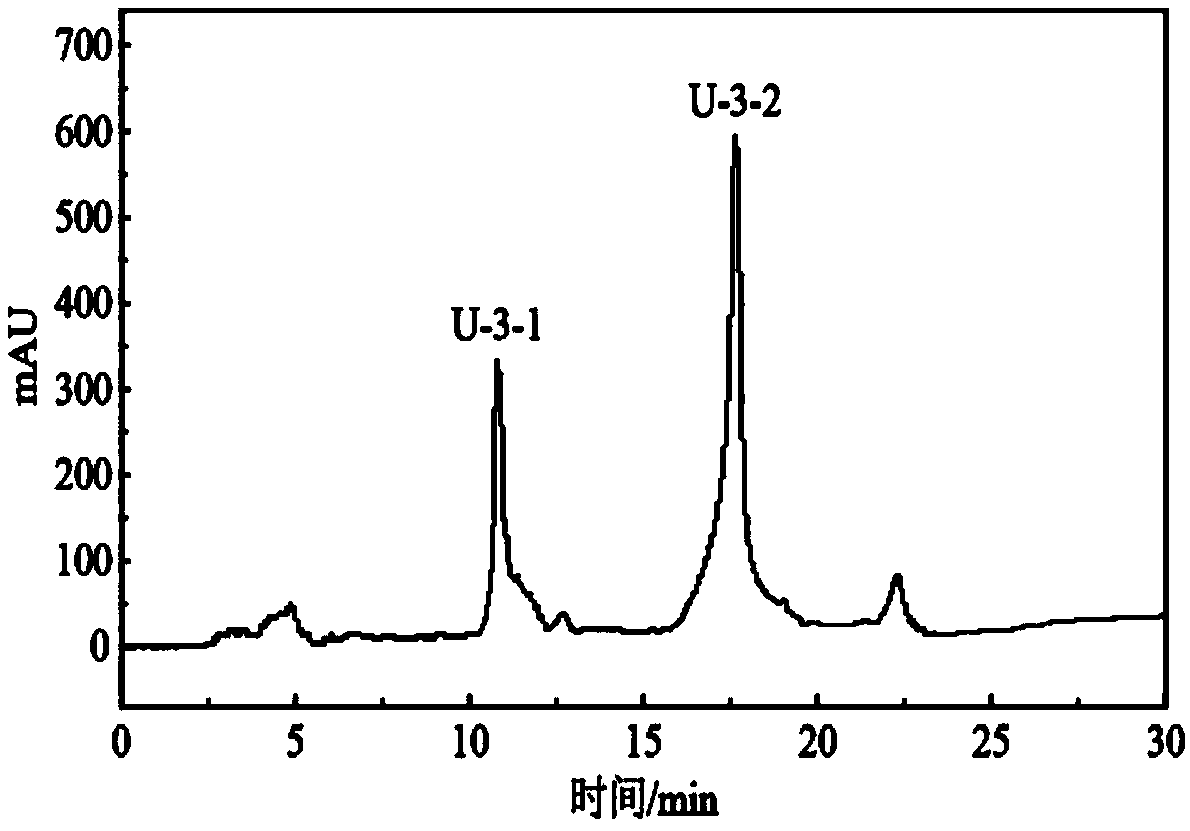

[0033] After ultrafiltration as described in Example 1, Sephadex G-15 gel chroma...

Embodiment 3

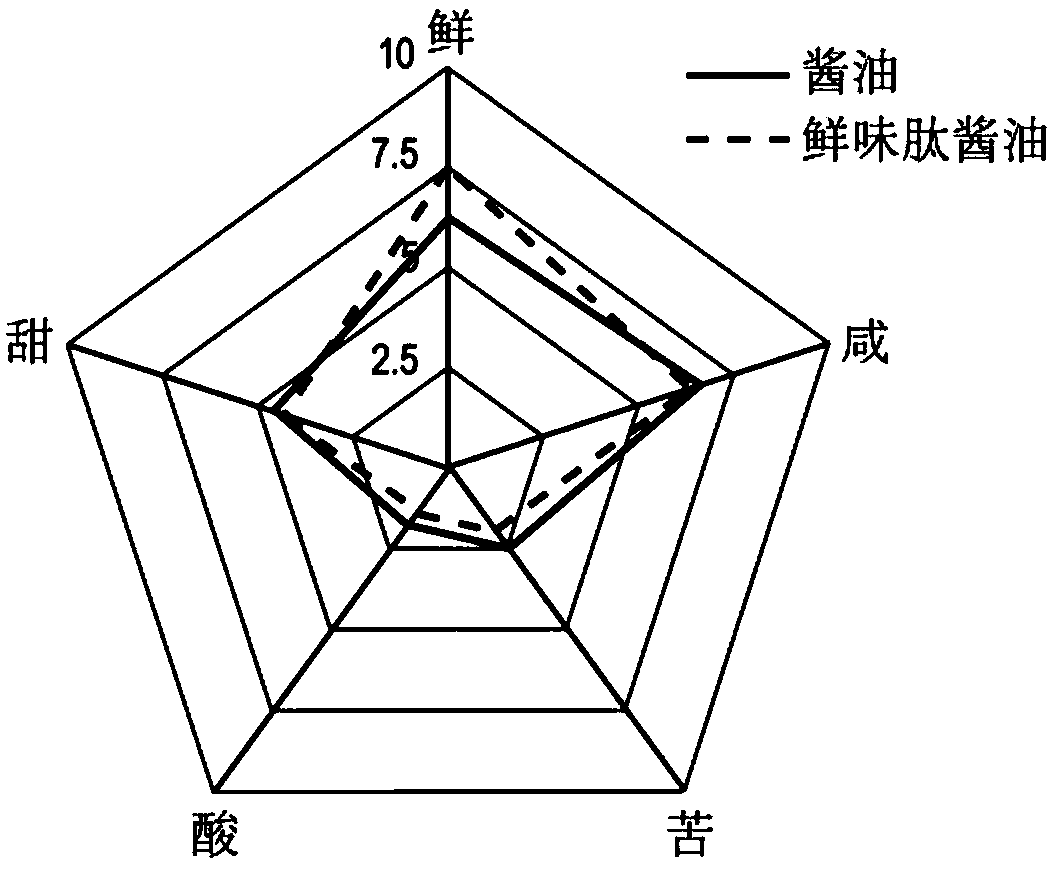

[0035] Using the umami peptide lyophilized powder in Example 2 as raw material, the lyophilized powder was added to soy sauce at a concentration of 0.3 mg / mL, and the soy sauce was labeled as umami peptide soy sauce. Randomly select 12 sensory assessors to carry out sensory evaluation, taking soy sauce as a control group, 0.08% citric acid solution, 1% sucrose solution, 0.08% quinine solution, 0.35% salt solution, 0.35% gluten The sodium phosphate solution was used as a taste standard solution for the five basic tastes of sour, sweet, bitter, salty, and fresh. The standard solution was used as 5 points, and the sensory evaluation of the umami peptide soy sauce solution was scored using a 10-point system to evaluate its taste. Flavor intensity. All samples are coded by 3-digit random numbers and then submitted to sensory evaluators for taste evaluation. The same sample is repeatedly evaluated 3 times, and the average value of the 3 measurements is taken as the final evaluation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com