Preparation method of visible light-responsive Fe3O4 quantum dot-modified BiOCl/BiVO4

A technology of visible light and quantum dots, applied in chemical instruments and methods, light water/sewage treatment, chemical/physical processes, etc., can solve the problem of low utilization rate of sunlight, achieve low cost, excellent photocatalytic activity, and facilitate batch production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

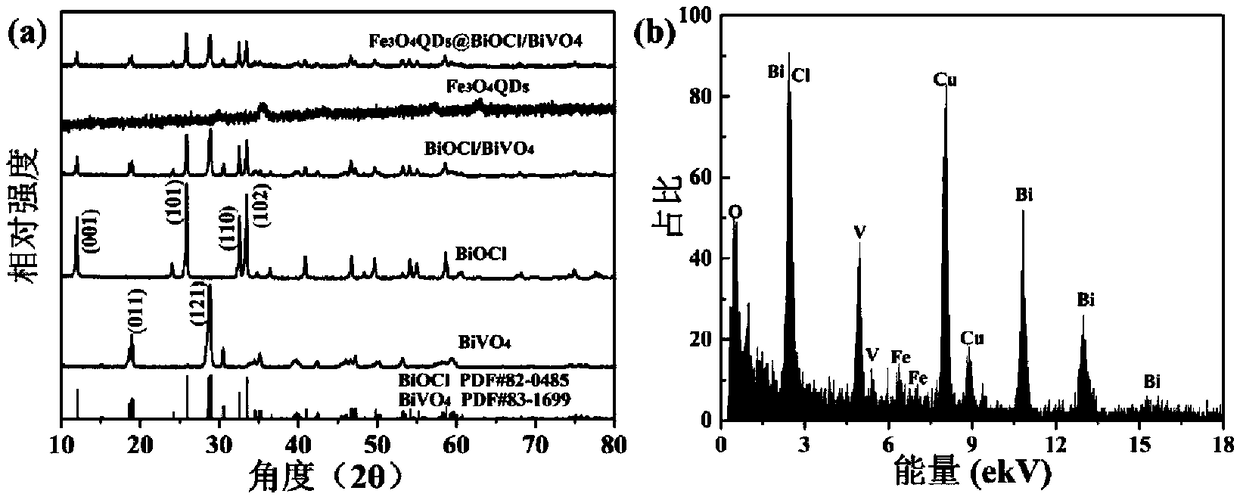

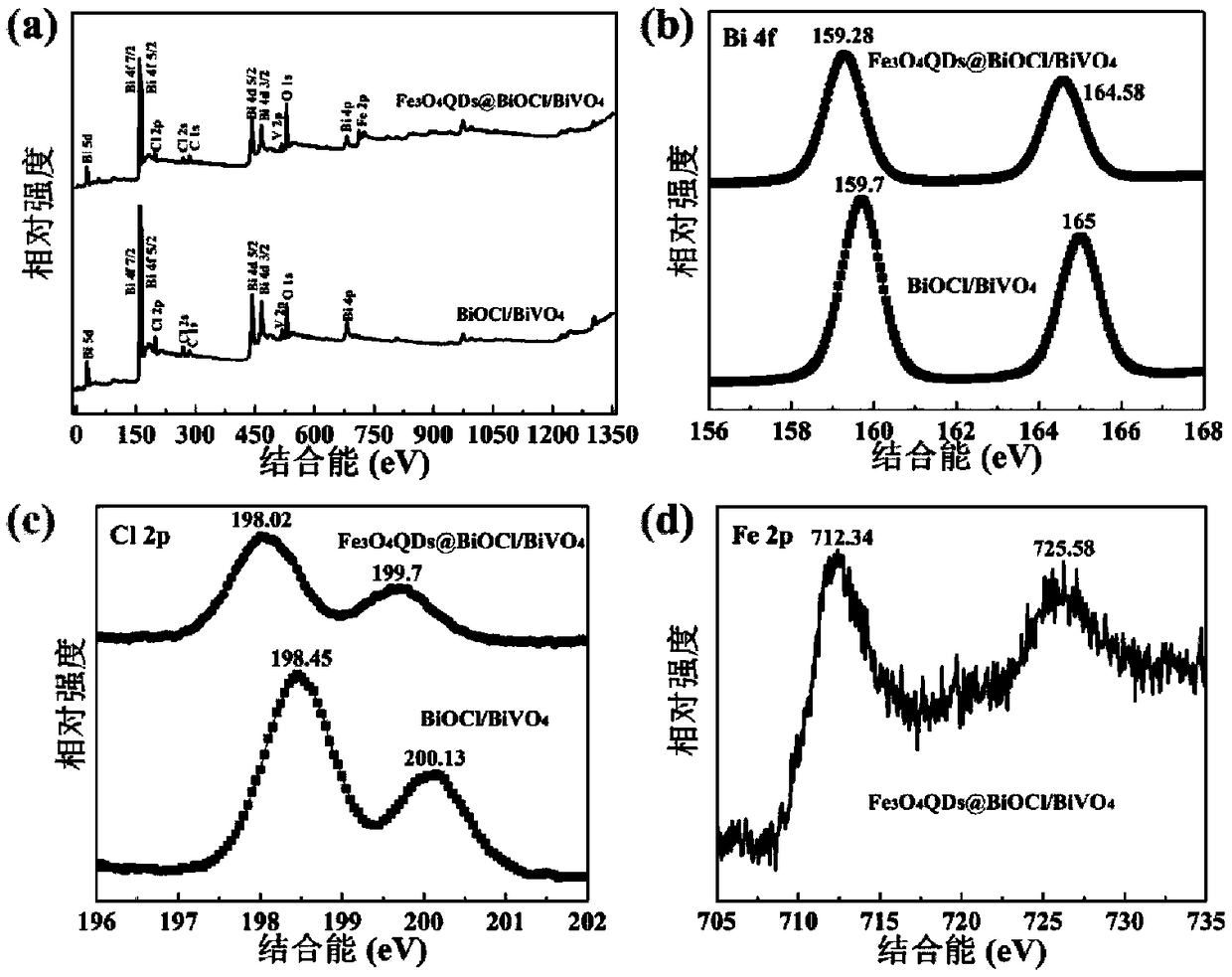

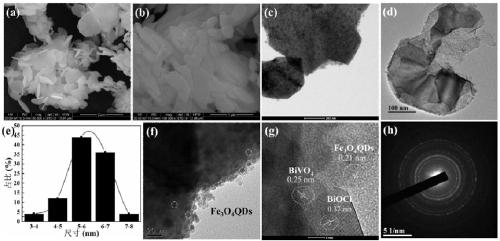

[0029] Visible light-responsive Fe 3 o 4 Quantum dot modified BiOCl / BiVO 4 A preparation method comprising the steps of:

[0030] 1) Preparation of BiOCl / BiVO by one-step hydrothermal method 4 catalyst of light

[0031] BiCl 3 and NH 4 VO 4 Mix in deionized water, add ethanolamine solution after stirring, transfer to a hydrothermal kettle for hydrothermal reaction; the reacted powder is washed, centrifuged, and dried to obtain BiOCl / BiVO 4 catalyst of light;

[0032] 2) Preparation of visible light-responsive Fe 3 o 4 Quantum dot modified BiOCl / BiVO 4

[0033] FeCl 3 ·6H 2 O and the BiOCl / BiVO prepared in step 1) 4 Photocatalysts were mixed and added to deionized water, and stirred to form solution A; meanwhile, the same molar mass of FeCl 2 4H 2 O is dispersed in deionized water, stirred to form solution B, drop B solution into A solution; and continue to add concentrated ammonia water to A solution while stirring; finally, the solid powder is collected by a m...

Embodiment 1

[0041] Embodiment 1: Synthesis of BiOCl / BiVO by one-step hydrothermal method 4 p-n heterojunction.

[0042] Take 0.3153g of BiCl 3 Dissolve in 50ml of water to form solution A, and stir for 30min under magnetic stirring. Another 0.17 g of NH 4 VO 4 Dissolve in 30ml (50°C) deionized water to form solution B, add solution B dropwise to solution A (with constant stirring at room temperature) at a rate of 10mL / min, and quickly add 1.5mL (1mol / L) ethanolamine, adjust the pH to 6.5-7.5. Then transfer to a hydrothermal kettle for hydrothermal reaction, and react at 160°C for 10h. The reacted powder was washed three times with water and ethanol respectively, centrifuged at 100rpm for 5min, and dried in a blast drying oven at 60°C for 12h to obtain BiOCl / BiVO 4 p-n heterojunction.

Embodiment 2

[0043] Embodiment 2: wet chemical method synthesis Fe 3 o 4 QDs-BiOCl / BiVO 4 p-n heterojunction.

[0044] First take 0.2315g BiOCl / BiVO 4 The p-n heterojunction was dispersed in 20mL deionized water, ultrasonically dispersed for 30min, and then FeCl was added at molar ratios of 3:10, 1:5, 1:10, and 1:20, respectively. 3 ·6H 2 O, BiOCl / BiVO 4 p-n heterojunction and FeCl 3 ·6H 2 The O mixed solution was sonicated for 10-20min, then transferred to a 75-85°C water bath, and kept stirring for 25-35min to form solution C. At the same time, FeCl 2 4H 2 O was dissolved in deionized water for 10 min, and solution D was formed after stirring, and solution D was quickly transferred to solution C. And under continuous stirring, 2mL of concentrated ammonia water was quickly added, and then continued to stir in a water bath at 80°C for 30min. Finally, the solid powder is collected by a magnet, washed three times with water and ethanol, and dried in a blast drying oven at 60°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com