Nano-oxide particle and Ni-based high-temperature alloy composite spherical powder for high-energy-beam 3D printing and preparation method thereof

A technology of nickel-based superalloy and nano-oxide, which is applied in the field of 3D printing and manufacturing, can solve the problems affecting the forming quality of high-energy beam 3D printing, the easy agglomeration of nano-scale reinforced particles, and the reduction of the sphericity of powder particles, etc., and the preparation method is simple and easy. Line, high sphericity, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

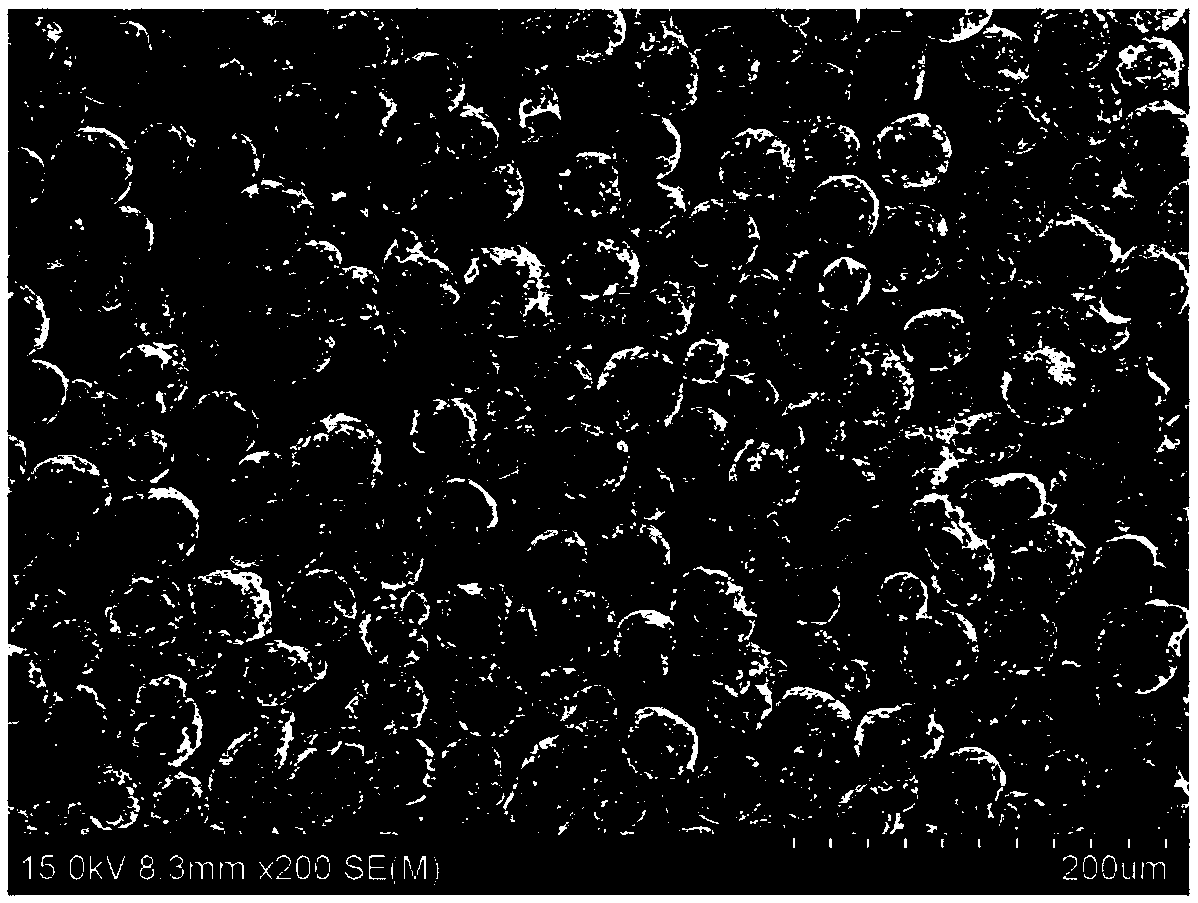

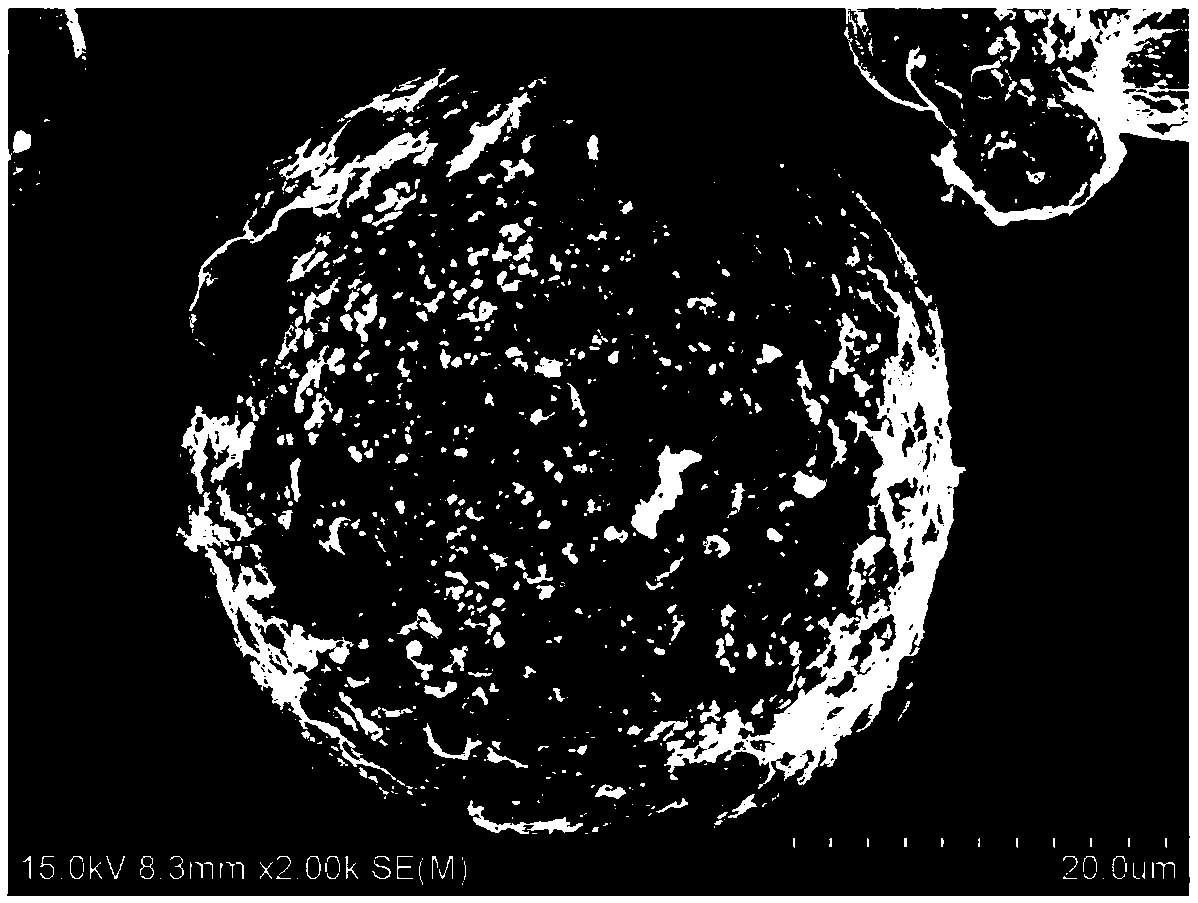

[0028] A nano-Al for high energy beam 3D printing 2 o 3 / Ni-based superalloy composite spherical powder and preparation method thereof, taking Ni-based superalloy as 100% by mass, nanometer Al 2 o 3 Powder accounted for 1%; Nano Al 2 o 3 The particle size of the nickel-based superalloy powder is 40nm, and the particle size of the nickel-based superalloy powder is 50μm.

[0029] The nano-Al 2 o 3 / Ni-based superalloy composite powder preparation method:

[0030] Step 1: Dissolve 0.5% polyethylene glycol dispersion / adhesive in 5% ethanol solvent to form a dispersion solution, add 1% Al 2 o 3 Nano-scale reinforcement particles were added to the solution, and subjected to high-energy ultrasonic crushing and dispersion treatment for 10 minutes;

[0031] Step 2: ultrasonically agitating the dispersed liquid after crushing in step 1 for 30 minutes to form a suspension of nano-reinforced particles;

[0032] Step 3: adding spherical nickel-based superalloy powder to the suspe...

Embodiment 2

[0035] A Nano ThO for High Energy Beam 3D Printing 2 / Ni-based superalloy composite spherical powder and preparation method thereof, taking nickel-based superalloy powder as 100% by mass percentage, nanometer ThO 2 Powder is 2%; Nano ThO 2 The particle size of the nickel-based superalloy powder is 30nm, and the particle size of the nickel-based superalloy powder is 40μm.

[0036] The Nano ThO 2 / Ni-based superalloy composite powder preparation method:

[0037] Step 1: Dissolve 1% polyethylene glycol dispersing / adhesive agent in 10% ethanol solvent to form a dispersion solution, add nano-scale reinforcing particles into the solution, and perform high-energy ultrasonic crushing and dispersion treatment for 25 minutes;

[0038] Step 2: ultrasonically agitating the dispersion liquid after crushing in step 1 for 40 minutes to form a suspension of nano-reinforced particles;

[0039] Step 3: adding the nickel-based superalloy spherical powder to the nano-reinforced particle suspe...

Embodiment 3

[0042] A Nano Y for High Energy Beam 3D Printing 2 o 3 / Ni-based superalloy composite spherical powder and preparation method thereof, taking nickel-based superalloy powder as 100% by mass, Y 2 o 3 Powder is 3%; Nano Y 2 o 3 The particle size of the nickel-based superalloy powder is 50nm, and the particle size of the nickel-based superalloy powder is 20μm.

[0043] The Nano Y 2 o 3 / Ni-based superalloy composite powder preparation method:

[0044] Step 1: Dissolve 1% polyethylene glycol dispersing / adhesive agent in 10% ethanol solvent to form a dispersion solution, add nano-scale reinforcing particles into the solution, and perform high-energy ultrasonic crushing and dispersion treatment for 30 minutes;

[0045] Step 2: ultrasonically agitating the dispersion liquid after crushing in step 1 for 40 minutes to form a suspension of nano-reinforced particles;

[0046] Step 3: adding the nickel-based superalloy spherical powder to the nano-reinforced particle suspension obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com