Sintered brick preparation process and special ageing silo

A preparation process and technology for sintered bricks, applied in the field of sintered bricks, can solve the problems of less control of raw material processing and long aging time, and achieve the effects of uniform distribution, uniform particle size, and easy aging time control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A sintered brick preparation process includes the steps of raw material crushing-powder screening-aging treatment-green body forming-wet green body drying-finished product roasting and the like.

[0058] Raw material pulverization steps: Take, for example, 45% of cinder, 20% of clay, 5% of coal gangue, 15% of fly ash, 5% of cement, and 5% of sodium silicate, and pulverize them into powders with the same particle size through a pulverizer to obtain the first mixing powder.

[0059] Powder screening: pass the prepared mixed powder into the screening device for screening. The sieving is divided into three sections, the first section is the primary screening of the mixed powder with larger particles, the second section is the secondary screening of the mixed powder coarse material, and the third section sieving the first The fine materials obtained after the stage screening and the second stage screening are collected and screened again through the metal separation equipme...

Embodiment 2

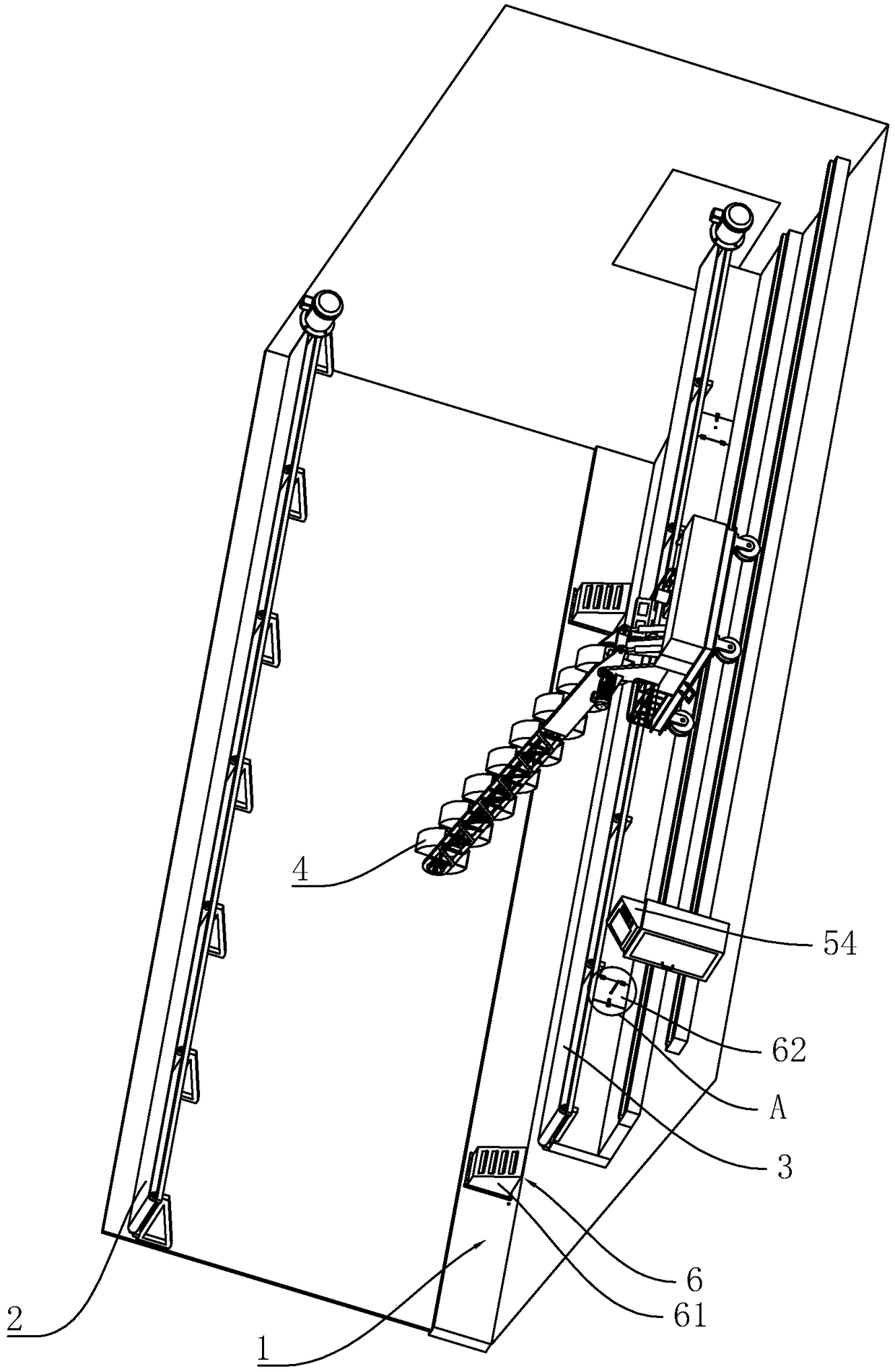

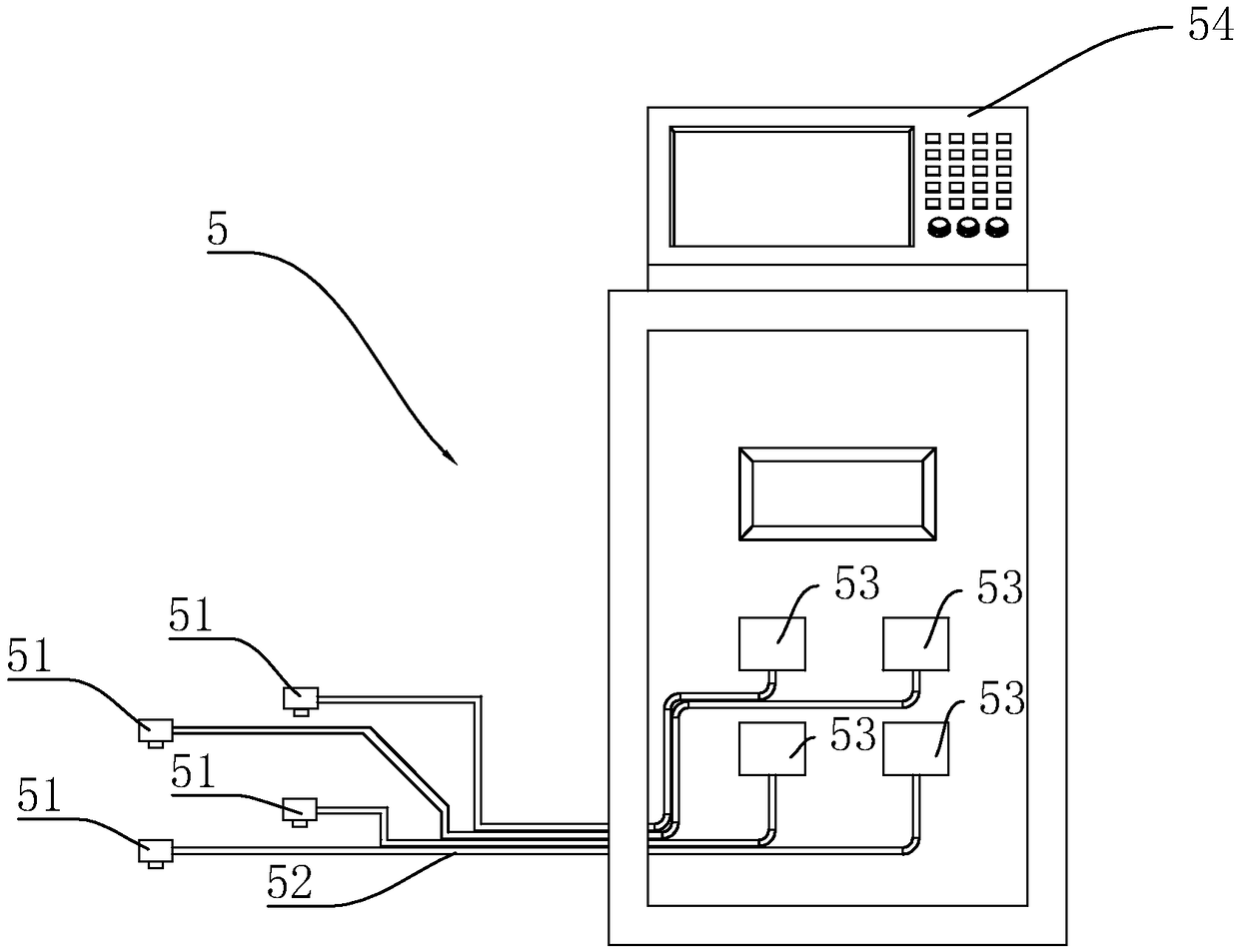

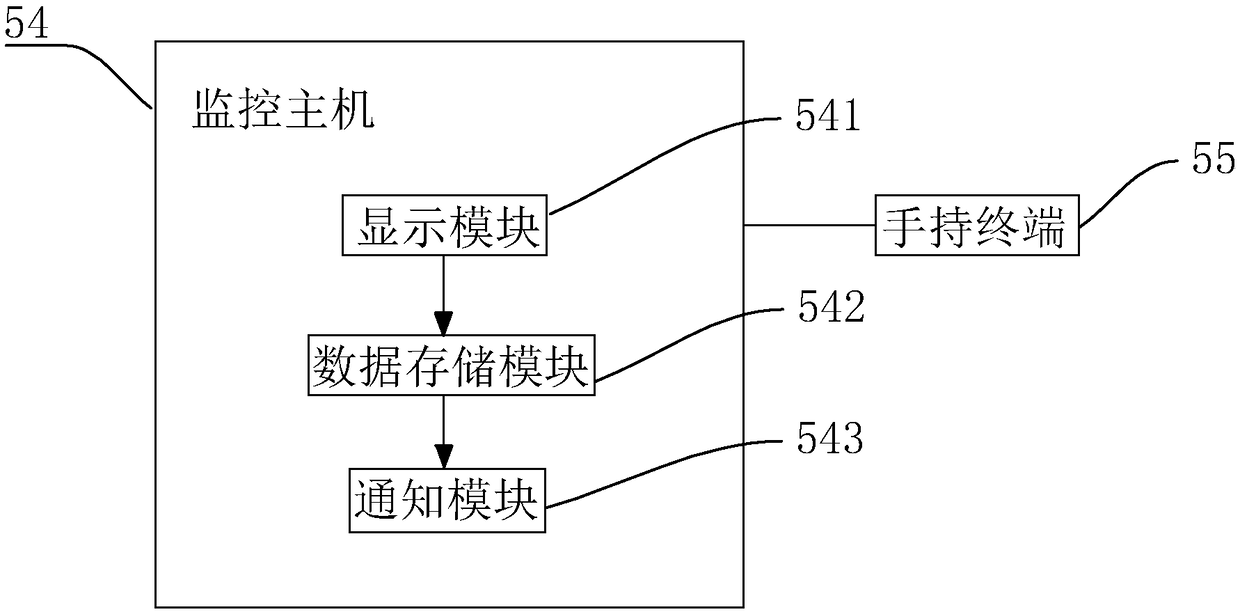

[0065] Such as figure 1 As shown, a dedicated aging warehouse for the preparation process of sintered bricks includes an aging warehouse 1 , a feeding conveyor belt 2 , a discharging conveyor belt 3 , and a hoist 4 . The aging warehouse 1 is formed by two low walls, and one of the walls is provided with a leaning plate against the wall, which is used for leaning on the stacked mixture. The top of the aging bin 1 is the feeding conveying belt 2 , the side is the discharging conveying belt 3 , and the outside of the discharging conveying belt 3 is the elevator 4 . The aging bin 1 is provided with a temperature and humidity monitoring system 5 and a number of detection bins 6 preset at the bottom of the aging bin 1, and stores the mixture to be aged, wherein the mixture surrounds the detection bin 6 to provide a humidity environment for the detection bin 6 . In this way, the improved aging warehouse can monitor the temperature and humidity of the aged mixture in real time, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com