A kind of preparation method of electrostatic spinning pan/bamboo charcoal powder nanofiber membrane filter material and product thereof

A technology of nanofiber membranes and filter materials, which can be used in spinning solution preparation, layered products, fiber treatment, etc., and can solve the problems of reducing the service life and filtration performance of air-conditioning filter elements, affecting the accuracy of instrument measurement, and affecting air quality, etc. , to achieve the effect of small fiber fineness, low penetration and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare the solution: first measure 44ml of DMF (density = 0.945-950g / ml) solvent and place it in a beaker, add 6g of polyacrylonitrile (PAN) powder into the solvent, place the beaker on an electric stirrer and stir it with a glass rod. Heat it for 60 minutes until it is completely dissolved, then let it cool naturally for 2 hours at room temperature at 20°C, take it out for use, and the solution after stirring is colorless and transparent;

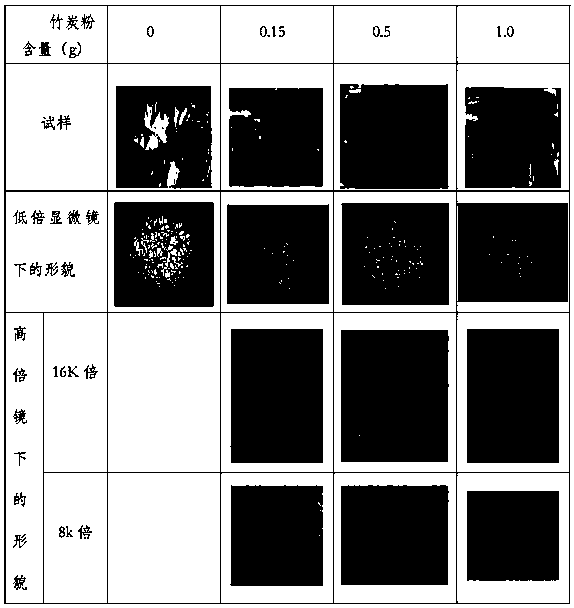

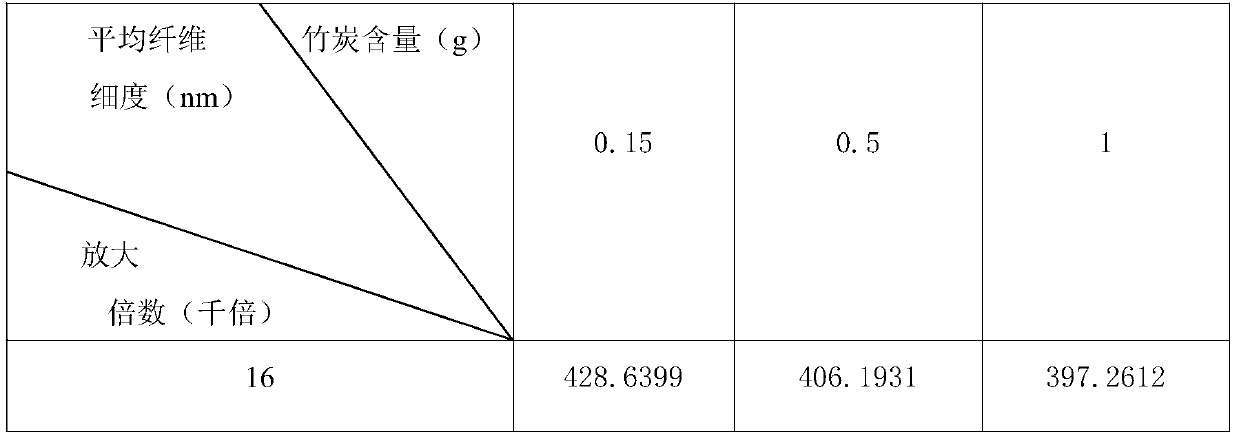

[0030] Add different contents of bamboo charcoal powder 0g, 0.15g, 0.5g, 1g respectively to prepare PAN bamboo charcoal solution, and stir on a magnetic stirrer for 3 hours;

[0031] Electrospinning: use electrospinning machine SH-01, electrospinning needle specifications: select the inner diameter of 0.41mm, outer diameter of 0.71mm, and length of 6.5mm. The distance is 30cm, the liquid feeding volume is 0.588ml / h, and different contents of PAN bamboo charcoal solutions are sprayed onto PP melt-blown non-woven fabrics to make pure...

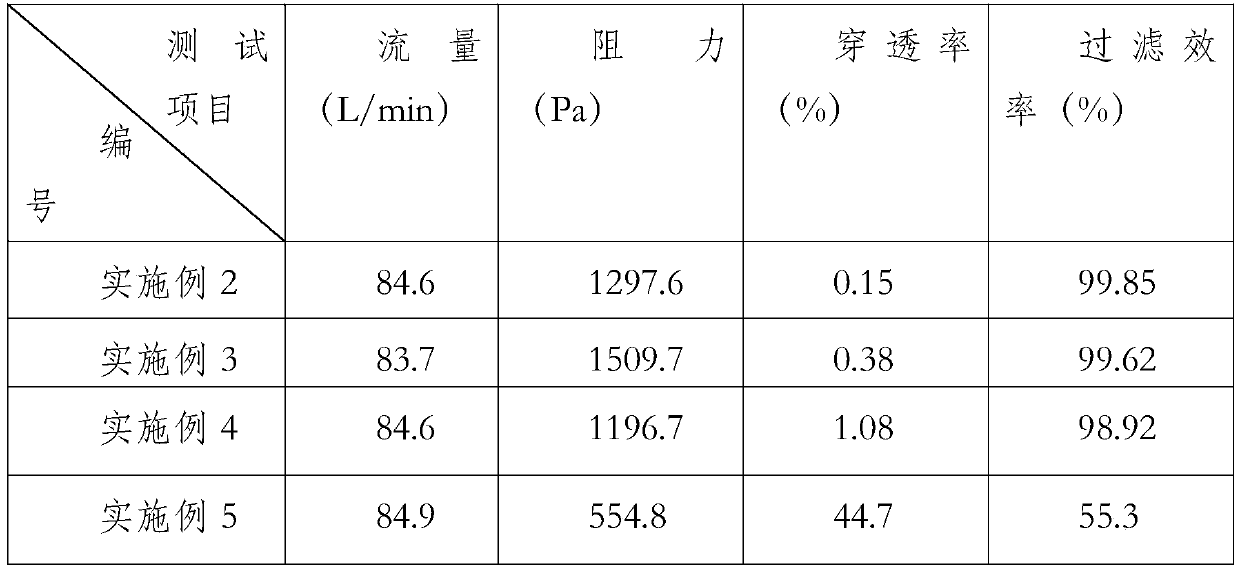

Embodiment 2

[0038] Preparation of polyacrylonitrile solution: first measure 44ml of DMF (N,N-dimethylformamide, density = 0.945-950g / ml) solvent in a beaker, add 6g of polyacrylonitrile (PAN) powder into the solvent, Place the beaker on an electric stirrer and stir it with a glass rod and heat it for 60 minutes until it is completely dissolved, then let it cool naturally for 2 hours at room temperature at 20°C, take it out for use, and the solution after stirring is colorless and transparent;

[0039] Add 1g of bamboo charcoal powder to prepare PAN bamboo charcoal solution, and stir on a magnetic stirrer for 3 hours;

[0040]Electrospinning: use electrospinning machine SH-01, electrospinning needle specifications: select the inner diameter of 0.41mm, outer diameter of 0.71mm, and length of 6.5mm. The distance is 30cm, the liquid feeding volume is 0.588ml / h, and under the same spinning time of 20 minutes, spray 1g of PAN bamboo charcoal solution onto the PP melt-blown non-woven fabric to m...

Embodiment 3

[0044] Prepare the solution: first measure 44ml of DMF (N,N-dimethylformamide, density = 0.945-950g / ml) solvent in a beaker, add 6g of polyacrylonitrile (PAN) powder to the solvent, and place the beaker Stir with a glass rod on an electric stirrer and heat it for 60 minutes until it is completely dissolved, then let it cool naturally at room temperature for 2 hours at 20°C, take it out for use, and the solution after stirring is colorless and transparent;

[0045] Electrospinning: use electrospinning machine SH-01, electrospinning needle specifications: select the inner diameter of 0.41mm, outer diameter of 0.71mm, and length of 6.5mm. The distance is 30cm, the liquid feeding volume is 0.588ml / h, and the PAN solution is sprayed onto the PP melt-blown non-woven fabric to make a PAN nanofiber membrane. The total electrospinning time of the PAN nanofiber membrane is 60min;

[0046] Preparation of nanofiber membrane filter material: 20cm×20cm PP non-woven fabric and electrospun na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com