A preparation method of liquid crystal polymer melt-blown non-woven fabric for high-temperature filtration

A technology of liquid crystal polymers and melt-blown non-woven fabrics, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of poor thermal stability, low melting point, etc., and achieve excellent filtering effect, melting Low viscosity, effect of increasing degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

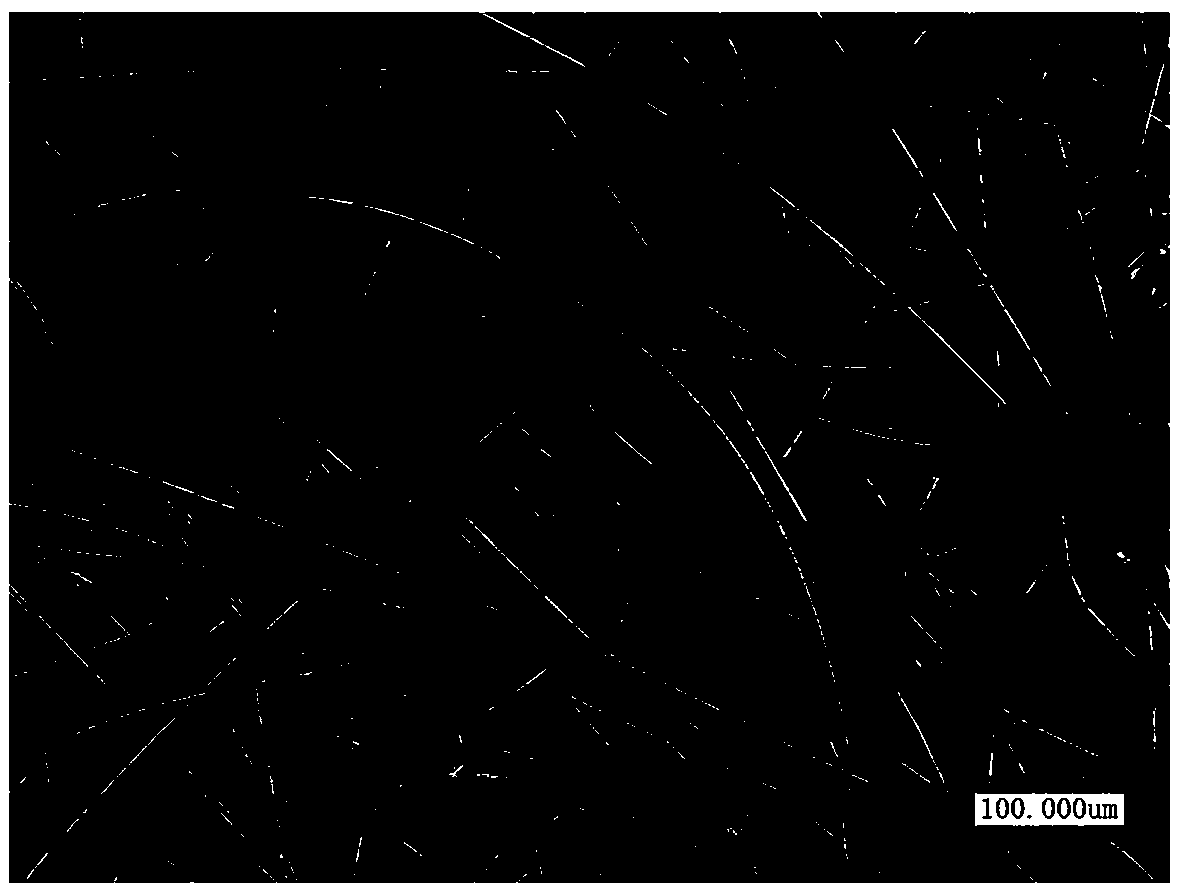

Image

Examples

Embodiment 1-7

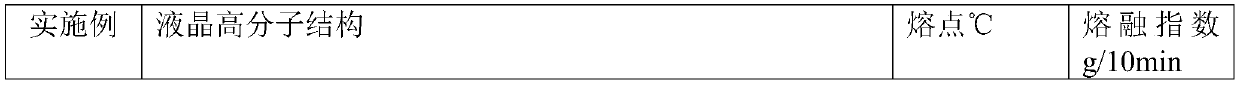

[0025] Examples 1-7, a liquid crystal polymer melt-blown non-woven fabric used for high-temperature filtration, the structural formula of the liquid crystal polymer used is shown in Table 1.

[0026] The polymerization process of the liquid crystal polymer used in the present invention is as follows:

[0027] The liquid crystal polymer of Example 1: react the monomers 6-hydroxy-2-naphthoic acid and p-hydroxybenzoic acid with excess acetic anhydride respectively, and obtain 6-acetoxy-2-naphthoic acid after washing, purification and drying (ANA) and acetoxybenzoic acid (ABA). ABA and ANA were added into the reactor at a molar ratio of 70:30, and zinc acetate was used as a catalyst in an amount of 0.2% of the total mass of the monomers. After exhausting the air in the reaction system with nitrogen, raise the temperature to 250°C and keep it for 3 hours, then raise the temperature to 280°C within 1 hour, keep it for 1.5 hours, then raise the temperature to 320°C, stop filling nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com