Axial-chirality bidentate ligand and application thereof in copper-catalyzed coupling reaction

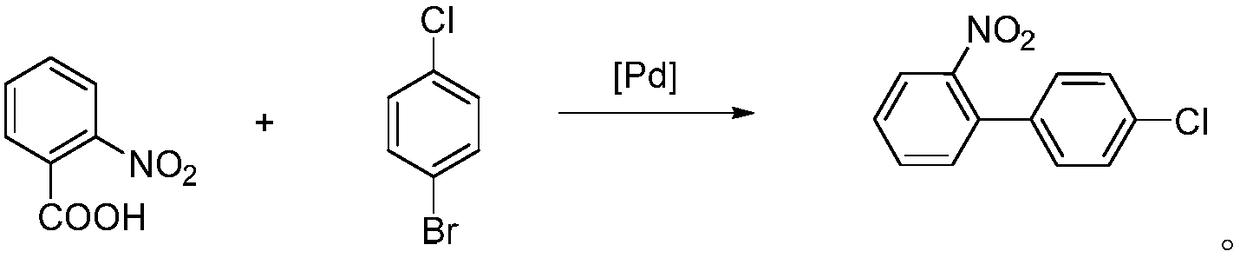

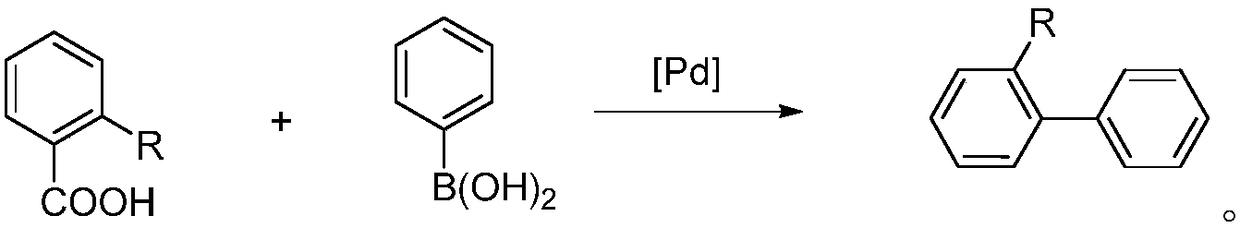

A bidentate ligand, coupling reaction technology, applied in catalytic reaction, organic compound/hydride/coordination complex catalyst, preparation of organic compounds, etc., can solve the problems of restricting large-scale application and high synthesis cost, and achieve The effect of mild reaction conditions, simple preparation and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 50mg of trimethoxyphenyl silicon and 45mg of bromobenzene into a 10mL single-port reaction flask, add 2mL of ethanol to dissolve, then add 35mg of KOH, add 5mol% of CuCl and A 1 After compounding the catalyst, the reaction was raised to 100° C., and the reaction was carried out for 6 hours. After the reaction was completed, it was directly passed through the column to obtain a white solid product with a yield of 56%.

Embodiment 2

[0018] Add 50mg of trimethoxyphenyl silicon and 45mg of bromobenzene into a 10mL single-port reaction flask, add 2mL of ethanol to dissolve, then add 35mg of KOH, add 5mol% of CuCl and A 1 After compounding the catalyst, the reaction was raised to 100° C. for 12 hours. After the reaction was completed, it was directly passed through the column to obtain a white solid product with a yield of 81%.

Embodiment 3

[0020] Add 50mg of trimethoxyphenyl silicon and 45mg of bromobenzene into a 10mL single-port reaction flask, add 2mL of ethanol to dissolve, then add 35mg of KOH, add 5mol% of CuBr and A 1 After compounding the catalyst, the reaction was raised to 100° C. for 12 hours. After the reaction, it was directly passed through the column to obtain a white solid product with a yield of 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com