Preparation method of flexible wearable strain sensor

A strain sensor, flexible technology, applied in the direction of electric/magnetic solid deformation measurement, textile and paper making, fiber processing, etc., to achieve the effect of enhancing bonding force, increasing specific surface area, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

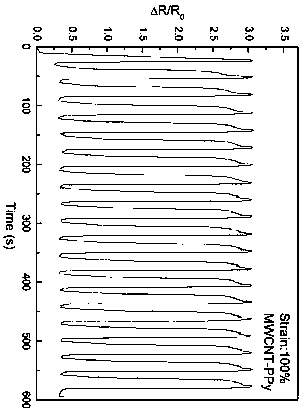

[0026] Prepare 30 mL of MWCNT solution with a concentration in the range of 0.001 g / mL, then add sodium dodecylsulfonate (the mass ratio of dispersant to MWCNT is 1:3), and disperse evenly in an ultrasonic machine. Stretch the fiber to a certain length (0-100%) and put it into the MWCNT dispersion for 3 minutes, then repeat the process 5 times.

[0027] Then the fibers dipped in the MWCNT conductive layer were immersed in 100 mL of pyrrole solution with a concentration of 0.1 mol / L for 20 minutes in an ice bath. 100 mL FeCl 3 ·6H 2 Mixed solution of O and sodium anthraquinone-2-sulfonate (FeCl 3 ·6H 2 O as an oxidant, sodium anthraquinone-2-sulfonate as a dopant) was dropped within 30 minutes, polymerized for 2 hours, and dried in an oven.

[0028] Finally, the fibers are assembled into strain sensors with copper foil and conductive glue.

Embodiment 2

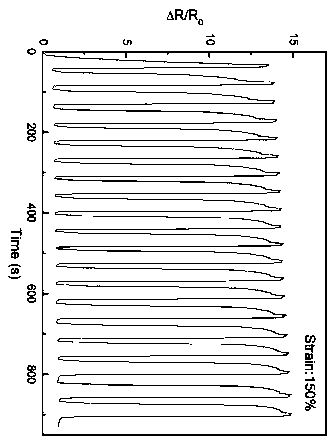

[0030] Prepare 30 mL of MWCNT solution with a concentration in the range of 0.005 g / mL, then add sodium dodecylsulfonate (the mass ratio of dispersant to MWCNT is 1:3), and disperse evenly in an ultrasonic machine. Stretch the fiber to a certain length (0-100%) and put it into the MWCNT dispersion for 3 minutes, then repeat the process 5 times.

[0031] Then the fibers dipped in the MWCNT conductive layer were immersed in 100 mL of pyrrole solution with a concentration of 0.1 mol / L for 20 minutes in an ice bath. 100 mL FeCl 3 ·6H 2 Mixed solution of O and sodium anthraquinone-2-sulfonate (FeCl 3 ·6H 2 O as an oxidant, sodium anthraquinone-2-sulfonate as a dopant) was dropped within 30 minutes, polymerized for 2 hours, and dried in an oven.

[0032] Finally, the fibers are assembled into strain sensors with copper foil and conductive glue.

Embodiment 3

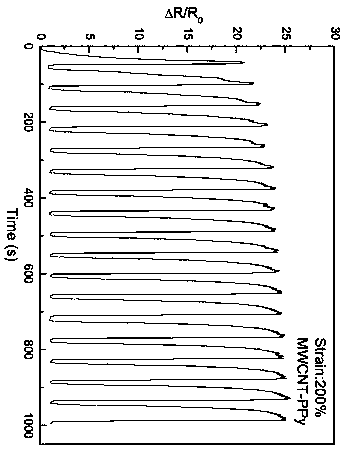

[0034] Prepare 30 mL of MWCNT solution with a concentration in the range of 0.003 g / mL, then add sodium dodecylsulfonate (the mass ratio of dispersant to MWCNT is 1:3), and disperse evenly in an ultrasonic machine. Stretch the fiber to a certain length (0-100%) and put it into the MWCNT dispersion for 3 minutes, then repeat the process 5 times.

[0035] Then the fibers dipped in the MWCNT conductive layer were immersed in 100 mL of pyrrole solution with a concentration of 0.1 mol / L for 20 minutes in an ice bath. 100 mL FeCl 3 ·6H 2 Mixed solution of O and sodium anthraquinone-2-sulfonate (FeCl 3 ·6H 2 O as an oxidant, sodium anthraquinone-2-sulfonate as a dopant) was dropped within 30 minutes, polymerized for 2 hours, and dried in an oven.

[0036] Finally, the fibers are assembled into strain sensors with copper foil and conductive glue.

[0037] In the technique of the present invention, the effects of stretching dip coating and polymerization are as follows:

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com