Strain sensor, structure monitoring system and manufacturing method

A strain sensor and structure monitoring technology, applied in the direction of electric/magnetic solid deformation measurement, instrument, measurement force, etc., can solve the problems of real-time health monitoring, small fiber deformation and expansion rate, fiber breakage failure, etc., to achieve small occupied space, A wide range of applications, the effect of reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

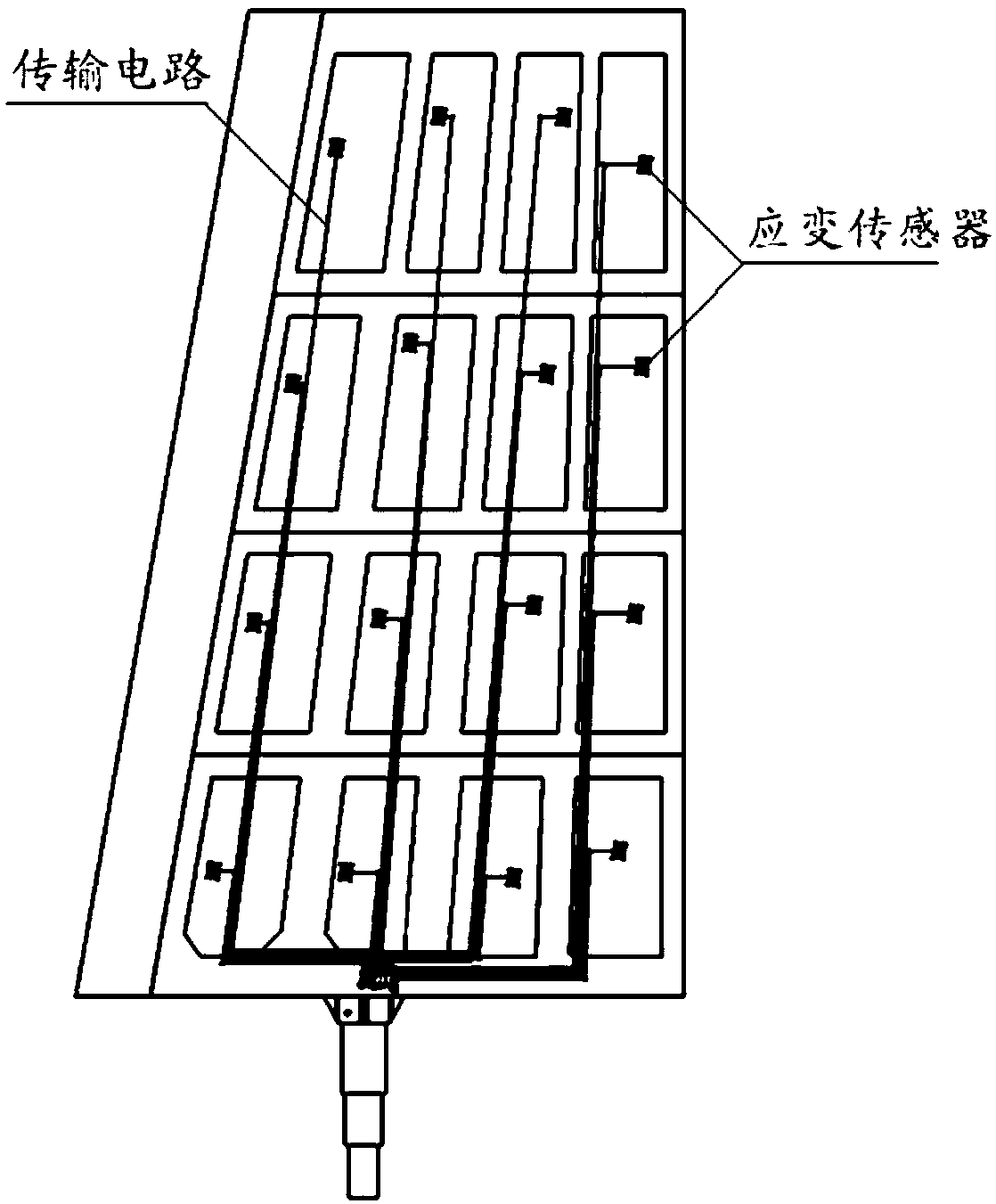

[0056] Taking an all-composite material rudder wing of a certain spacecraft as an example, the specific implementation steps of the technical solution of the present invention are described.

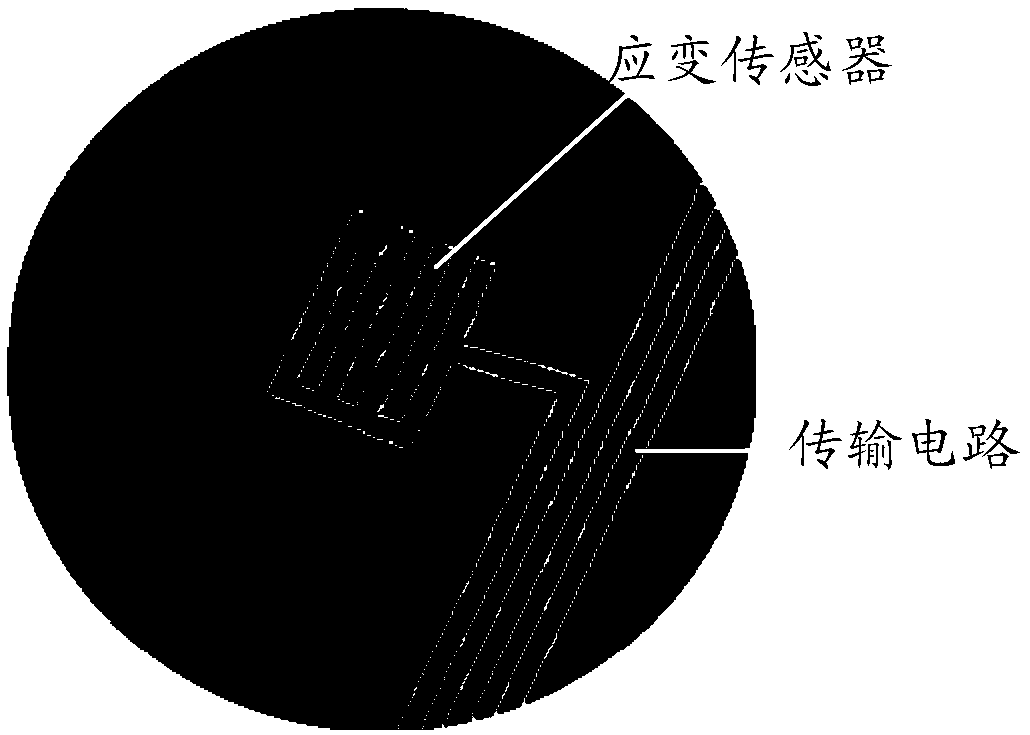

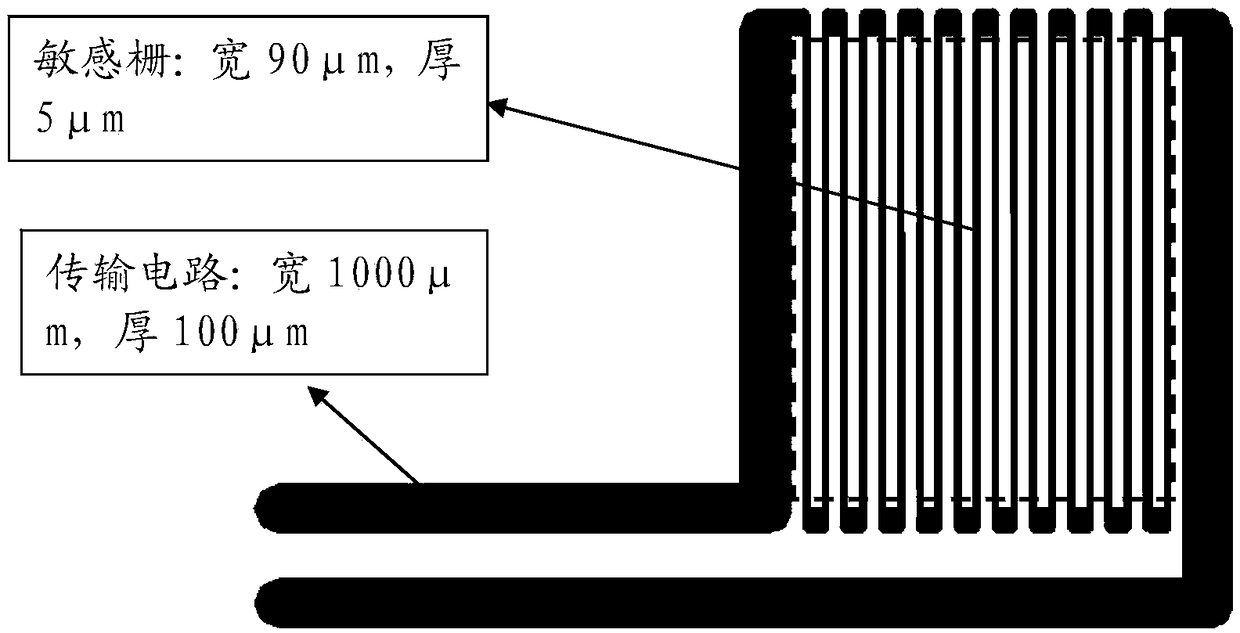

[0057] (1) Design the structure monitoring circuit according to the structure scheme of the rudder wing. First, determine the monitoring position of the strain sensor and the direction of the transmission circuit, such as figure 1 shown. Then design the direction of the sensitive grid of the strain sensor of the structure monitoring circuit and the size of the strain sensor, such as figure 2 shown. The longitudinal direction of the sensitive grid of the strain sensor should be consistent with the local maximum deformation direction of the structure, and the maximum deformation direction can be determined by the finite element simulation results. Then design the length, width and thickness of the strain sensor and the transmission circuit. During the design, it is necessary to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com