POSS (Polyhedral Oligomeric Silsesquioxane) organic-inorganic hybrid molecular imprinted monolithic column capable of specifically recognizing ochratoxin A and preparation method of monolithic column

A technology of ochratoxin and molecular imprinting, applied in the field of analytical chemistry, can solve the problems that the advantages are not fully demonstrated, and achieve the effect of high-efficiency enrichment and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

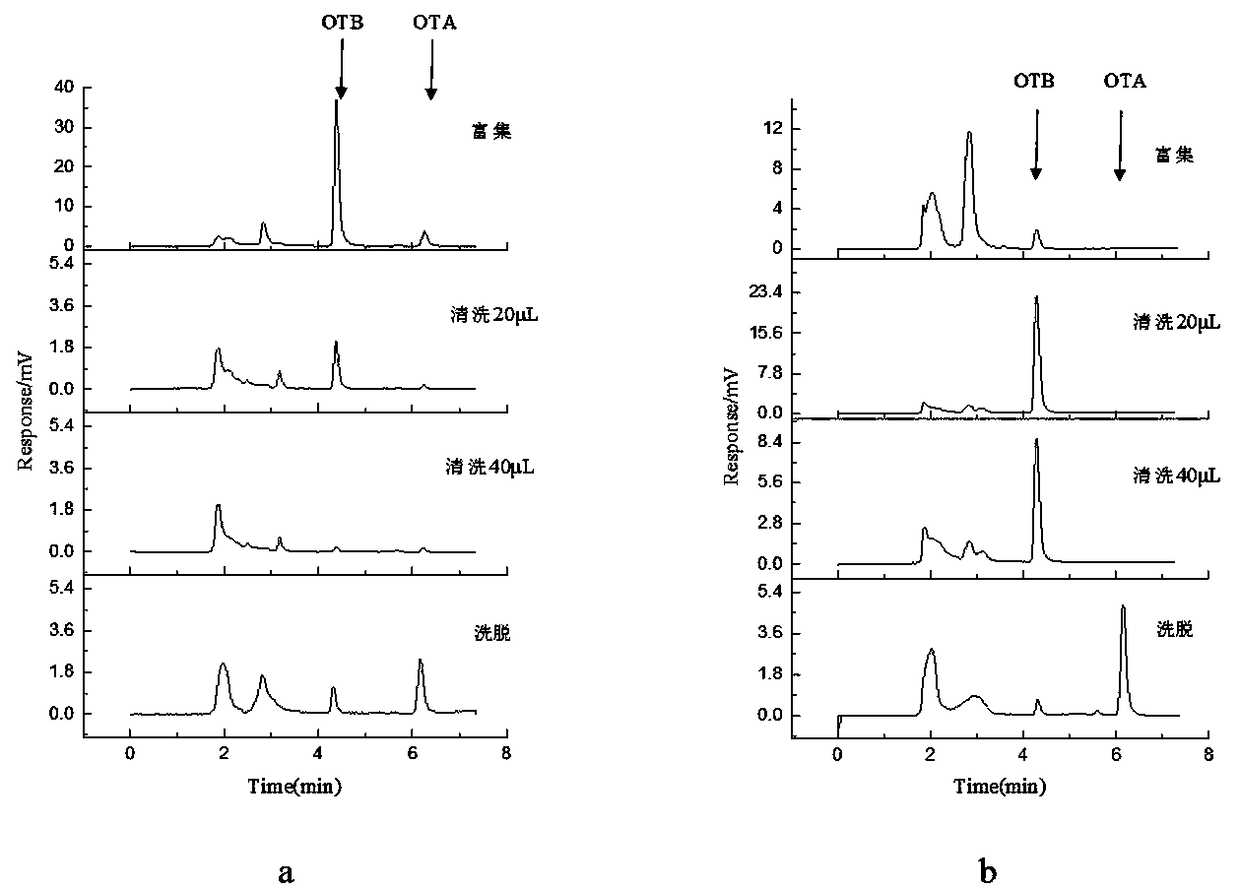

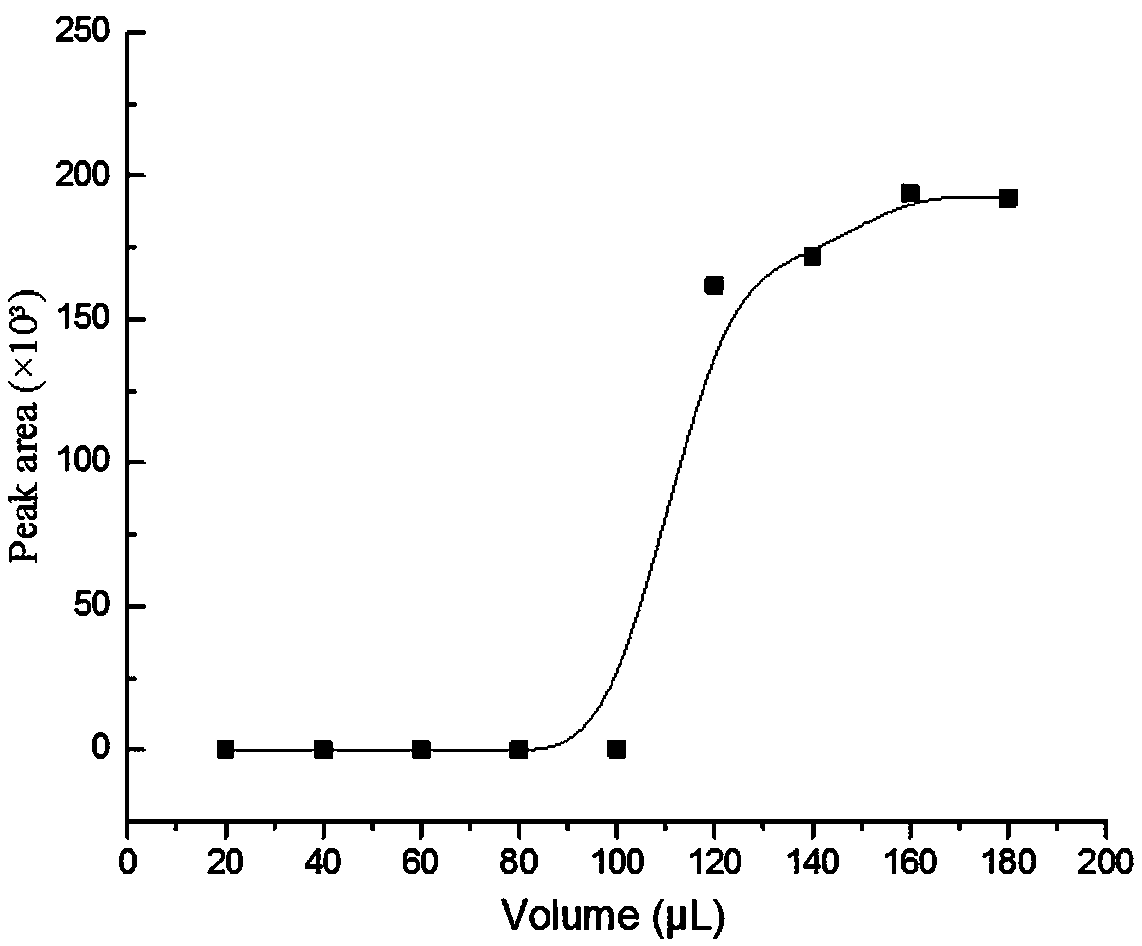

Image

Examples

Embodiment 1

[0031] A POSS organic-inorganic hybrid molecularly imprinted monolithic column that specifically recognizes ochratoxin A and a preparation method thereof, the specific steps are:

[0032] (1) Quartz capillary column pretreatment: wash the fused silica capillary with 0.1 mol / L HCl for 30 minutes, distilled water for 30 minutes, 0.1 mol / L NaOH for 3 hours, distilled water and methanol for 30 minutes, and then Dry at room temperature with 0.4 MPa nitrogen flow for 30 min; in order to introduce C=C bonds into the inner surface of the capillary to bond the hybrid matrix, a 50% volume percent γ-MAPS methanol (v / v) solution was injected into the capillary, Both ends were sealed with silicone rubber, and then the capillary was heated in a water bath at 60 °C for 24 h; after that, the capillary was rinsed with methanol for 30 min, and then dried at 70 °C for 30 min by 0.4 MPa nitrogen for further use;

[0033] (2) According to the mass ratio of 12.7 : 3.8 : 83.5, accurately weigh 2-acr...

Embodiment 2

[0037] A template with an ochratoxin A concentration of 250 ppb was added, and the other steps were as in Example 1 to obtain column A.

Embodiment 3

[0039] A template with a concentration of ochratoxin A of 750 ppb was added, and other steps were as in Example 1 to obtain column C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com