Method for detecting content of total iron in vanadium titanium powder

A detection method and technology of vanadium and titanium powder, applied in the field of analytical chemistry, can solve the problems of slow filtration in the melting process, fast production rhythm of enterprises, and complicated operation, and achieve the effect of simple operation process, short analysis period and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

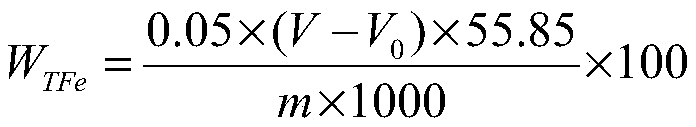

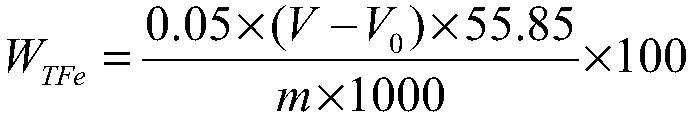

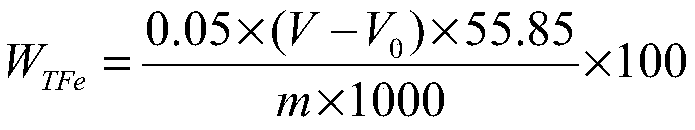

Image

Examples

Embodiment 1

[0052] In the present embodiment, a kind of method of detection total iron content in vanadium titanium powder is provided, and described detection method comprises the steps:

[0053] (1) taking by weighing the vanadium-titanium powder sample to be measured that is 0.2g is placed in 500mL volumetric flask, adds 25mL sulfur-phosphorus mixed acid, wherein the volume ratio of sulfuric acid, phosphoric acid and water in the sulfur-phosphorus mixed acid is 3:3:4, Heat to dissolve, evaporate and emit white smoke, and when the white smoke leaves the bottom of the container for 5-7cm, cool naturally to obtain a mixed solution;

[0054] (2) adding concentration to the mixed solution prepared by step (1) is 30mL of 38% concentrated hydrochloric acid, boils, drips concentration and is 60g / L tin protochloride solution, until obtaining light yellow solution, drips 10 drops concentration is 250g / L sodium tungstate solution is used as an indicator, and a titanium trichloride solution with a...

Embodiment 2

[0062] In the present embodiment, a kind of method of detection total iron content in vanadium titanium powder is provided, and described detection method comprises the steps:

[0063] (1) Take by weighing the vanadium-titanium powder sample that is 0.1g to be measured and place in 500mL volumetric flask, add 20mL sulfur-phosphorus mixed acid, wherein the volume ratio of sulfuric acid, phosphoric acid and water in the sulfur-phosphorus mixed acid is 3:3:4, Heat to dissolve, evaporate and emit white smoke, and when the white smoke leaves the bottom of the container for 5-7cm, cool naturally to obtain a mixed solution;

[0064] (2) adding concentration to the mixed solution prepared by step (1) is 20mL of 38% concentrated hydrochloric acid, boils, drips concentration and is 50g / L tin protochloride solution, until obtaining light yellow solution, drips 8 drops concentration is 250g / L sodium tungstate solution is used as an indicator, and a titanium trichloride solution with a con...

Embodiment 3

[0072] In the present embodiment, a kind of method of detection total iron content in vanadium titanium powder is provided, and described detection method comprises the steps:

[0073] (1) The vanadium-titanium powder sample to be measured that takes by weighing 0.5g is placed in the 500mL volumetric flask, adds 30mL sulfur-phosphorus mixed acid, wherein the volume ratio of sulfuric acid, phosphoric acid and water in the sulfur-phosphorus mixed acid is 3:3:4, Heat to dissolve, evaporate and emit white smoke, and when the white smoke leaves the bottom of the container for 5-7cm, cool naturally to obtain a mixed solution;

[0074] (2) adding concentration to the mixed solution that step (1) prepares is the concentrated hydrochloric acid 40mL of 37%, boils, and dripping concentration is 70g / L tin protochloride solution, until obtaining light yellow solution, drips 10 drops concentration is 300g / L sodium tungstate solution is used as an indicator, and a titanium trichloride soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com