High-sulfur supported lithium-sulfur battery positive electrode, preparation method of lithium-sulfur battery positive electrode, and lithium-sulfur battery

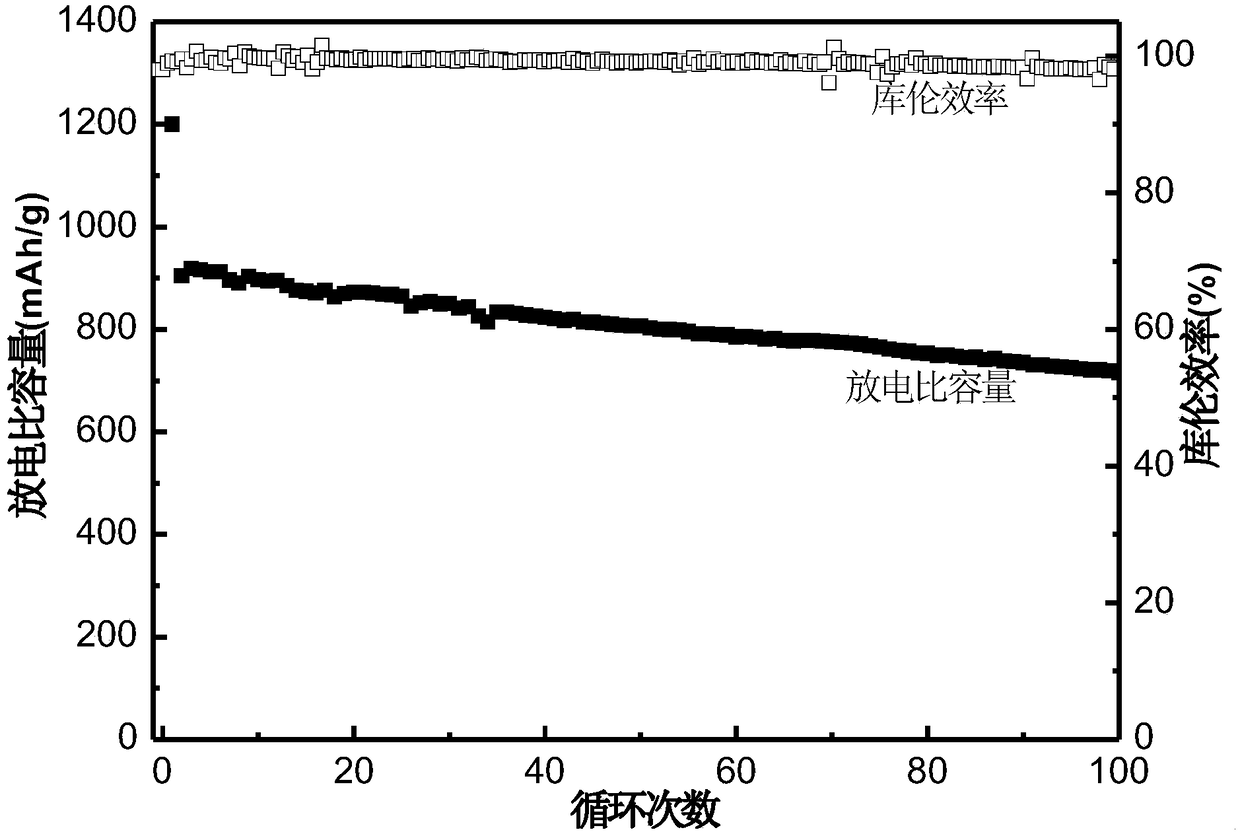

A lithium-sulfur battery and positive electrode technology, which is applied in the high-sulfur-loaded lithium-sulfur battery positive electrode and its preparation, and in the field of lithium-sulfur batteries, can solve the problems of difficult sulfur infiltration technology, uneven distribution of sulfur, and failure to meet the application requirements. Achieve the effect of improving electrochemical performance, improving coating quality and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

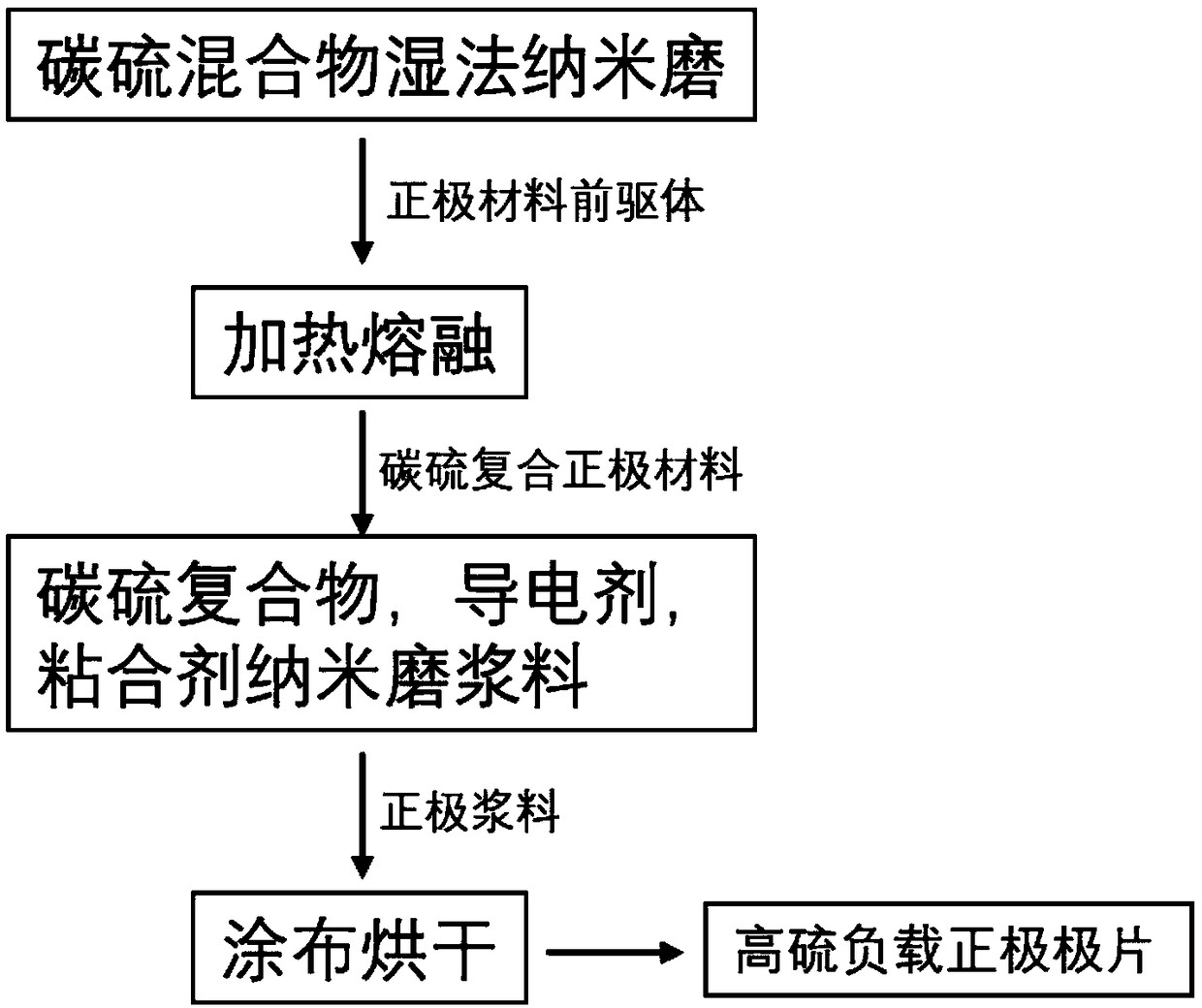

[0035] A method for preparing a positive electrode of a high-sulfur-loaded lithium-sulfur battery of the present invention, the schematic diagram of the process flow is as follows figure 1 shown, including the following steps:

[0036](1) 100g Ketjen Black and 500g sulfur are added to 2.4kg of pure water, mix uniformly to obtain a carbon-sulfur mixed slurry, then add the carbon-sulfur mixed slurry to the barrel of a sand mill and carry out nano ball milling, the ball milling speed is 1000rpm, the ball milling time 30min;

[0037] (2) Dry the carbon-sulfur mixed slurry after step (1) in a blast oven at 80°C for 20 hours, pulverize it, then transfer it to a vacuum oven, and melt it at 155°C for 12 hours to obtain Ke Piano black / sulfur composite cathode material;

[0038] (3) Add the Ketjen black / sulfur composite positive electrode material, carbon nanotubes, and La133 binder after step (2) into water according to the mass ratio of 7:2:1, and mix well to prepare the lithium-sul...

Embodiment 2

[0042] A method for preparing a positive electrode of a high-sulfur-loaded lithium-sulfur battery of the present invention, comprising the following steps:

[0043] (1) 100g of carbon nanotubes and 500g of sulfur are added to 1.8kg of pure water, mixed uniformly to obtain a carbon-sulfur mixed slurry, then the carbon-sulfur mixed slurry is added to the barrel of a sand mill for nano ball milling, the ball milling speed is 1100rpm, and the ball milling time 20min;

[0044] (2) Dry the carbon-sulfur mixed slurry after step (1) in a blast drying oven at 90°C for 15 hours, pulverize it, then transfer it to a vacuum oven, and heat-melt it at 165°C for 10 hours to obtain carbon Nanotube / sulfur composite cathode materials;

[0045] (3) Add the carbon nanotube / sulfur composite positive electrode material, SuperP, and La133 binder after step (2) into water at a mass ratio of 7:2:1, and mix well to prepare the lithium-sulfur battery positive electrode slurry precursor body, and then a...

Embodiment 3

[0049] A method for preparing a positive electrode of a high-sulfur-loaded lithium-sulfur battery of the present invention, comprising the following steps:

[0050] (1) 80g Ketjen Black, 20g carbon nanotubes and 500g sulfur are added to 2kg of pure water, mix uniformly to obtain a carbon-sulfur mixed slurry, then add the carbon-sulfur mixed slurry to the barrel of a sand mill and carry out nano ball milling, the ball milling speed is 1200rpm, ball milling time is 40min;

[0051] (2) Dry the carbon-sulfur mixed slurry after step (1) in a blast drying oven at 60°C for 20 hours, pulverize it, then transfer it to a vacuum oven, and heat-melt it at 160°C for 10 hours to obtain Ke Qinhei-carbon nanotube / sulfur composite cathode material;

[0052] (3) Ketjen black-carbon nanotubes / sulfur composite positive electrode material, carbon nanotubes, and La132 type binder after step (2) are added to water according to the mass ratio of 6:3:1, and lithium is obtained after mixing evenly Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com