Method for extracting potassium from fly ash hydrolysate

A water washing and fly ash technology, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the problems of unstable equipment operation, complex components, and high salt concentration, and achieve improved The effect of cost-effectiveness, simplification of the preprocessing process, and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

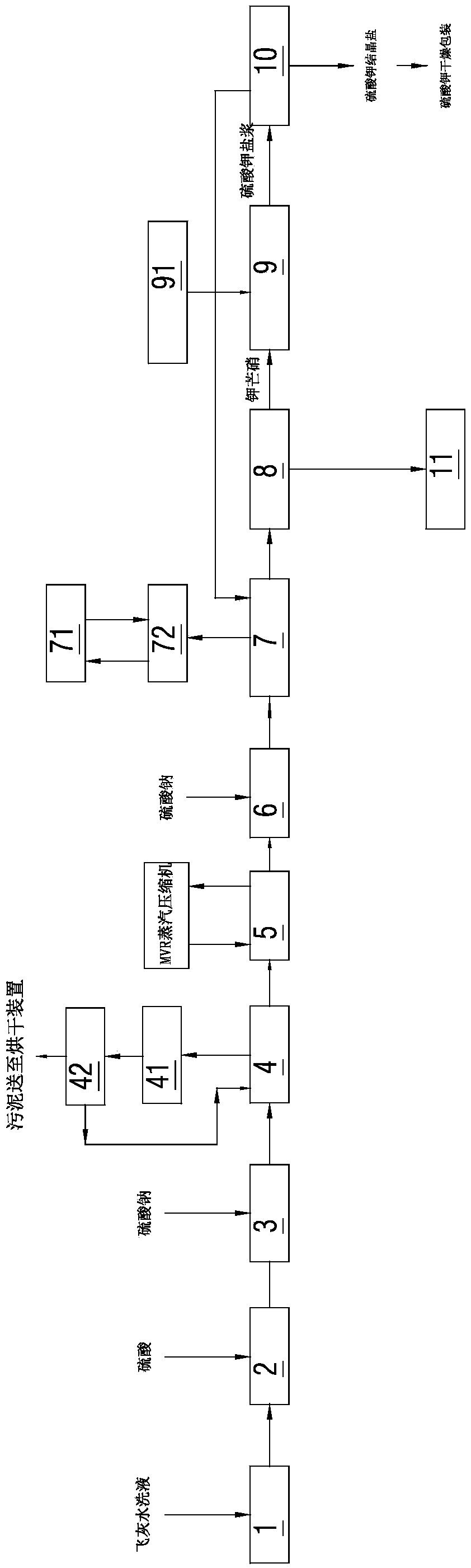

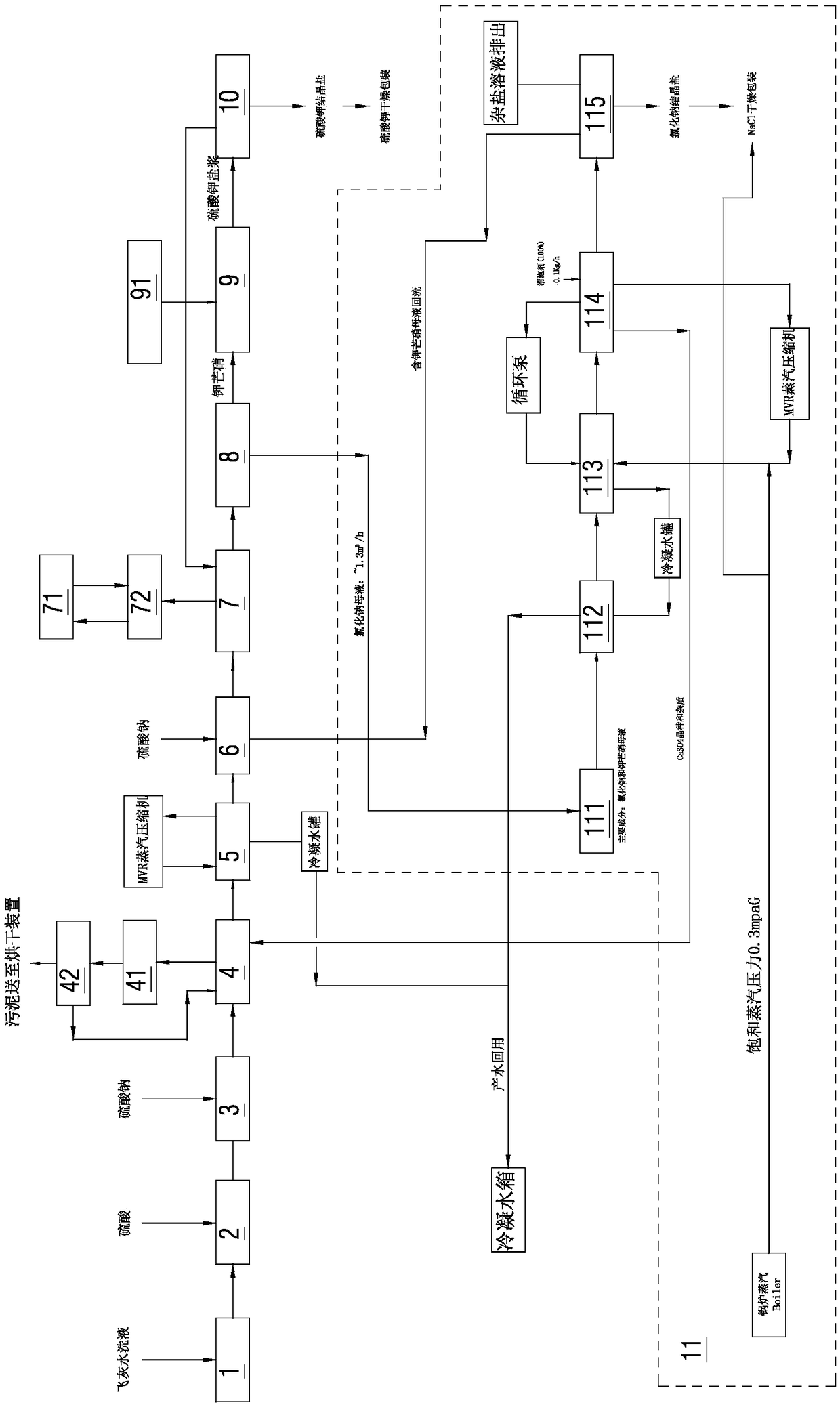

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0024] The invention provides an overall process route with advanced technology and simple pretreatment, which can realize the recovery of relatively high-purity potassium sulfate salt and sodium chloride salt. Potassium sulfate is used as one of the basic raw materials of agricultural compound fertilizers, and its market value is very high. High, sodium chloride is widely used as industrial salt.

[0025] figure 1 Shown is a schematic diagram of the principle of a method for extracting potassium from fly ash washing liquid according to a specific embodiment of the present invention, see figure 1 Shown, a kind of method for extracting potassium from fly ash washing liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com