Method for preparing fuel oil by co-processing of solid waste and coal tar

A technology for solid waste and coal tar, which is applied in the treatment of hydrocarbon oil, hydrotreating process, tar processing through distillation, etc. It can solve the problems of poor quality of light fuel oil, lower device economy, lack of effective management, etc. Achieve high hydrogen-carbon ratio, reduce energy consumption, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

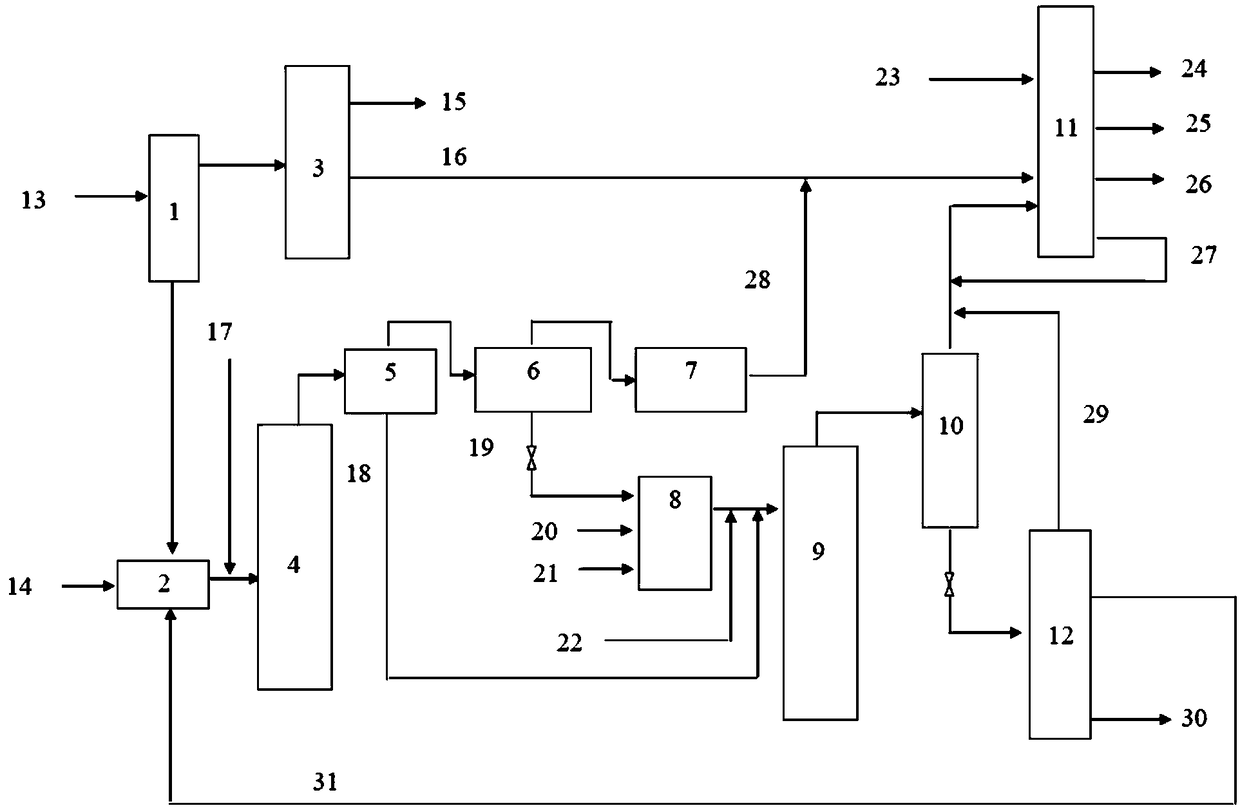

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] see figure 1 , the coal tar 13 is sent to the distillation unit 1 for separation, and the separated light components enter the tar phenol extraction unit 3 to obtain crude phenol 15 and raffinate oil 16, and the heavy components, heavy oil hydrogenation catalyst 14, and circulating oil slurry 31 enter the mixing tank 2 After being fully stirred, enter the pre-hydrogenation reaction device 4 together with the hydrogen gas 17; the pre-hydrogenation reaction device 4 consists of three plug-flow reactors connected in series with the lower feed and upper discharge, with an operating pressure of 16MPa and a temperature of 437°C. The oil volume ratio is 1100, and the space velocity is 1.42h -1 The gas-liquid product of the pre-hydrogenation reaction unit 4 enters the first gas-liquid separator 6, the second gas-liquid separator 7, and the third gas-liquid se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com