A low-rank coal hydrogenation-pyrolysis-gasification coupled integrated polygeneration process method

A technology of low-rank coal and polygeneration, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of low operating pressure of gasifier, short service life of catalyst, difficulty in effective utilization, etc., and achieve improvement The overall operation economy, reducing the pulverization degree of semi-coke, and realizing the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

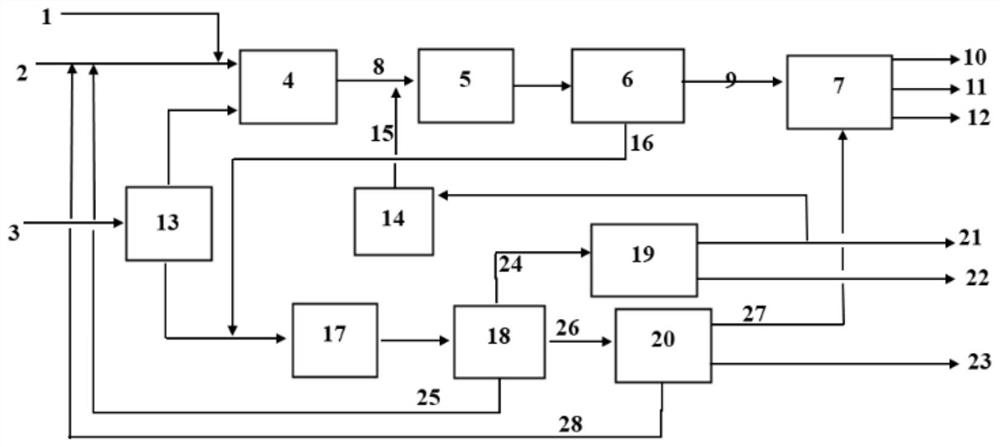

[0032] The present invention will be further described in detail below with reference to the accompanying drawings.

[0033] Such as figure 1 As shown: The low-order coal 3 enters the powder unit 13 to obtain different particle size of pulverized coal by breaking, grinding, drying, sieving, etc., and enters the oil coal slurry preparation unit 4 and the pyrolysis unit 17; low-order coal 3 The volatile content is not less than 30% by weight, the ash is less than 10% by weight, the water content is not higher than 3%, the H / C atom ratio is not less than 0.64, and the pulverized coal size of the oil coal slurry preparation unit 4 is 100 ~ Between the 250 mesh, the pulverized particle diameter size of the pyrolysis unit 17 is between 30 and 60;

[0034] The pulverization coal from the powder unit 13 and the lyvolus oil 28 of the foreign heavy oil 2, the cyclone separation unit 18, the redentification of the distillation unit 20, and the catalyst 1 are sufficiently mixed into the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com