A combined process of coal tar processing and coal co-smelting

A combined process and coal tar technology, applied in the chemical industry, can solve the problems of low content of polycyclic aromatic hydrocarbons, easy coking of reactants, poor hydrogen supply capacity, etc., and achieve the effects of improving conversion efficiency, preventing coking, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

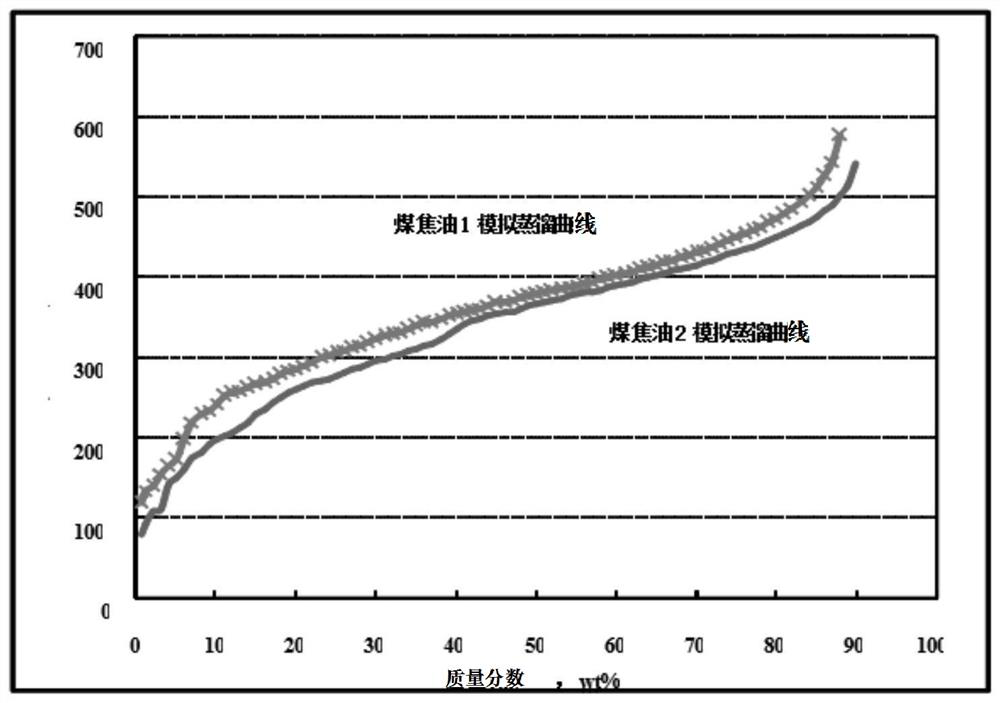

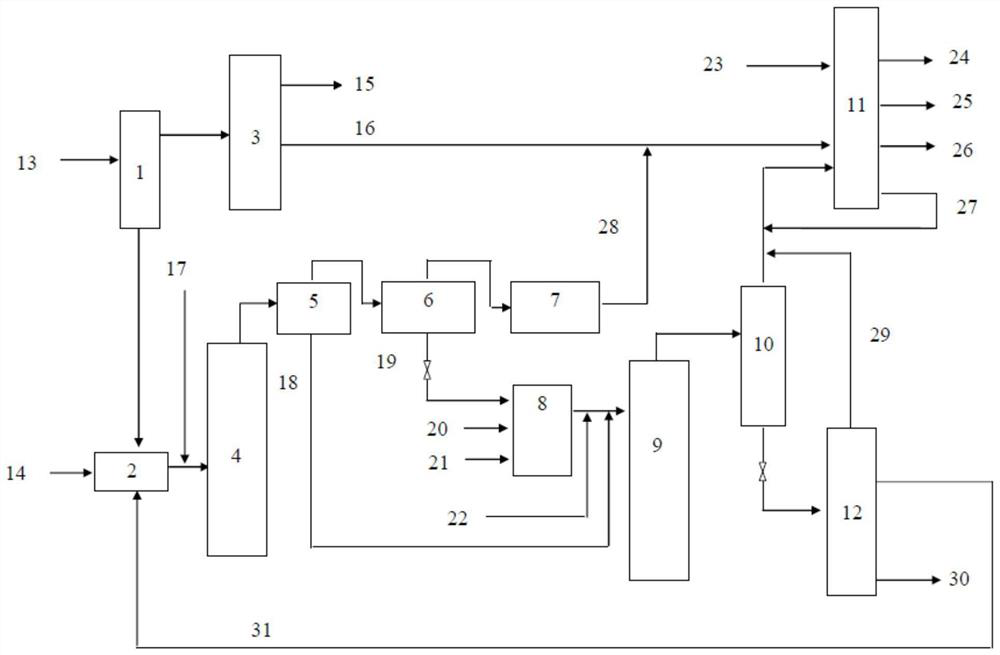

[0036] see figure 1 figure 2 , the coal tar 13 is sent to the distillation unit 1 for separation, and the separated light components enter the tar phenol extraction unit 3 to obtain crude phenol 15 and raffinate oil 16, and the heavy components, heavy oil hydrogenation catalyst 14, and circulating oil slurry 31 enter the mixing tank 2 After being fully stirred, enter the pre-hydrogenation reaction unit 4 together with the hydrogen gas 17; the pre-hydrogenation reaction unit 4 includes three bubbling bed reactors connected in series, the operating pressure is 16MPa, the temperature is 447°C, the volume ratio of hydrogen to oil is 1600, and the air The speed is 1.42h -1 The gas-liquid products of the pre-hydrogenation reaction unit 4 enter the hot high-pressure separator 5, the medium-temperature high-pressure separator 6, and the low-temperature high-pressure separator 7 successively to obtain high-temperature solvent oil 18, low-temperature solvent oil 19 and light oil 28, a...

Embodiment 2

[0038] Example 2 adopts the same process flow as Example 1, the difference is that the operating pressure of the bubbling bed reactor in the pre-hydrogenation reaction device is 16MPa, the temperature is 450°C, the volume ratio of hydrogen to oil is 1600, and the space velocity is 1.54h -1 At the same time, medium and low temperature coal tar 2 with high colloid and asphaltene content is used as raw material, and the concentration of oil-coal slurry entering the kerosene co-refining reaction device is 43%.

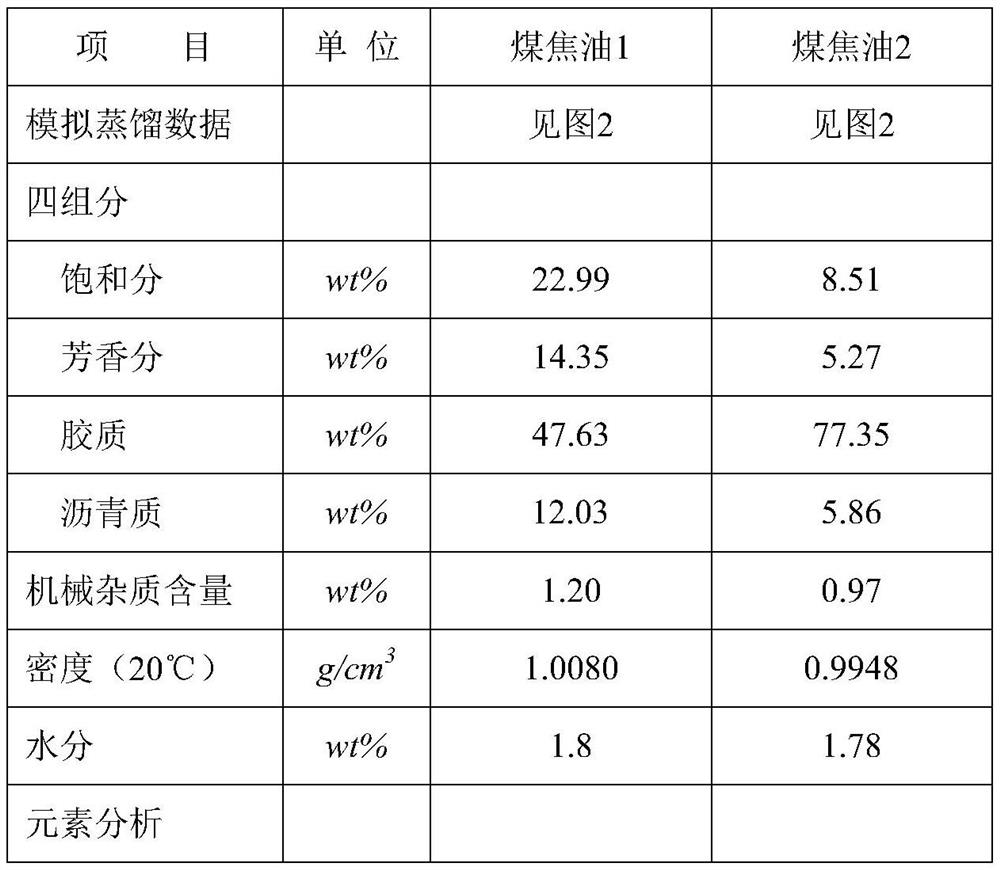

[0039] Properties of low temperature coal tar in Table 1

[0040]

[0041]

[0042] Table 2 Dry basis coal powder properties

[0043] project unit West Bay Cleaned Coal Industrial Analysis Ash wt% 8.40 Volatile matter wt% 34.02 Elemental analysis carbon content wt% 75.06 hydrogen content wt% 4.38 Sulfur content wt% 0.54 nitrogen content wt% 0.94 oxygen content wt% 10.36 H / C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com