Method of converting phlorizin into phloretin

A technology of phloridzin and phloretin, applied in the biological field, can solve the problems of difficult industrialized large-scale production, poor conversion specificity, high cost, etc., achieve good dispersion effect and improve the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

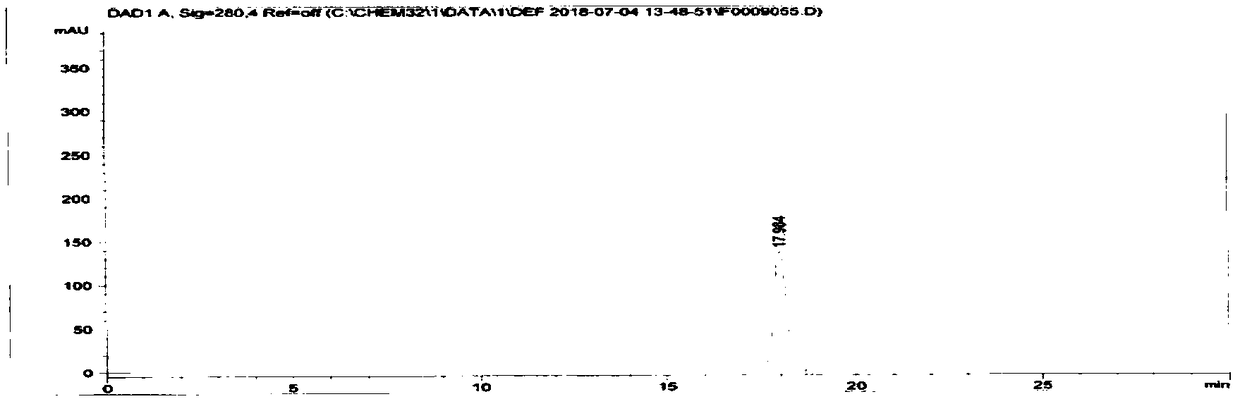

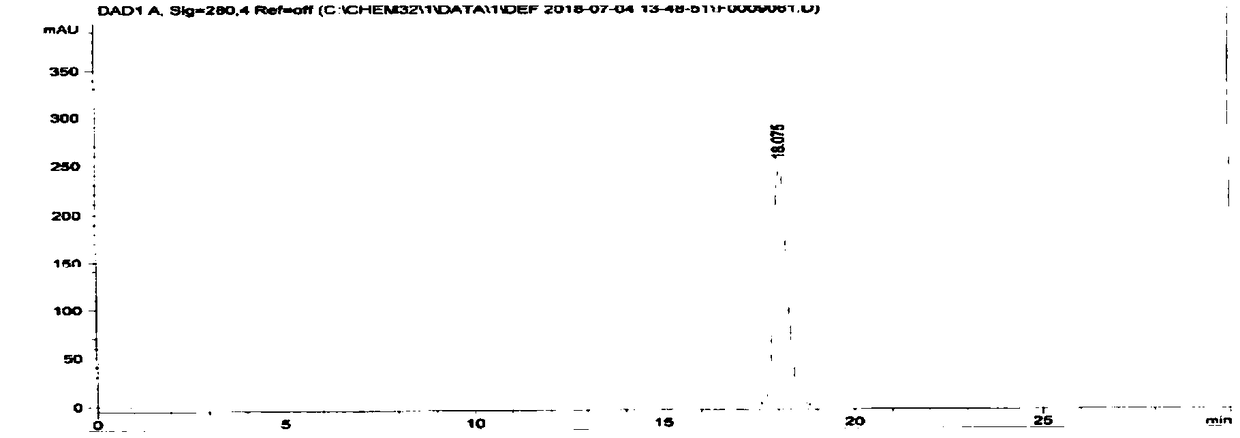

Image

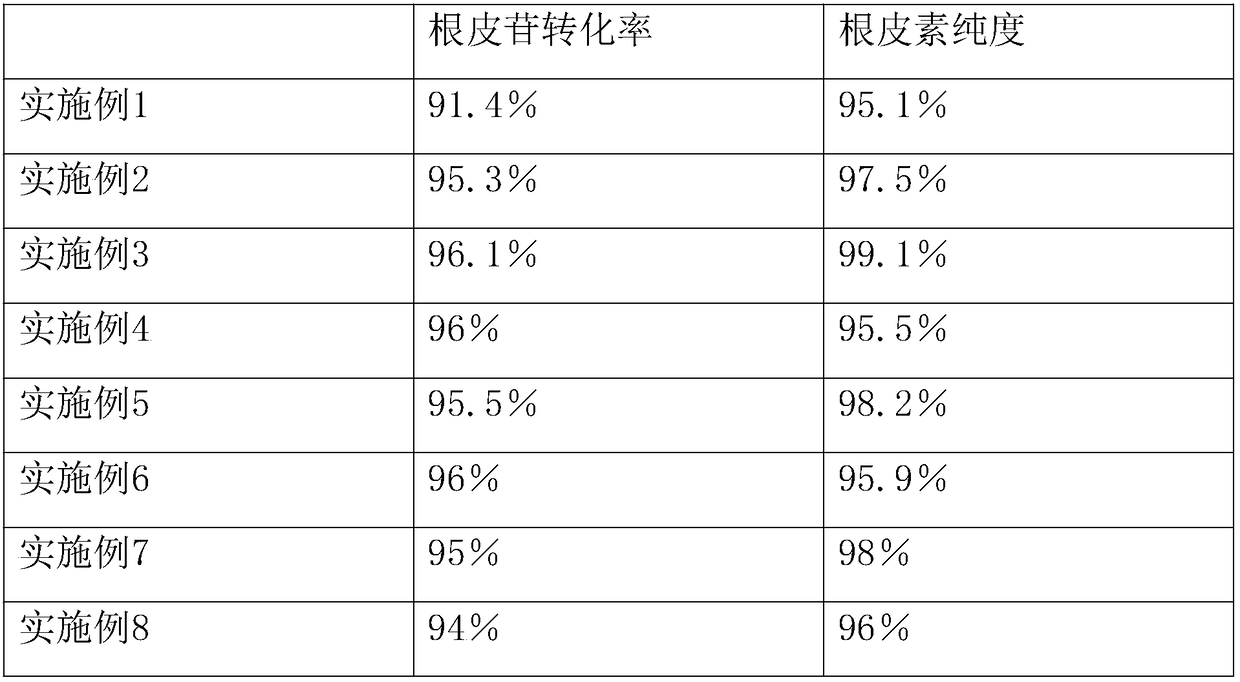

Examples

Embodiment 1

[0036] Add water into the reaction tank, use hydrochloric acid to adjust the pH value to 3.5, and add the dry powder containing 80% mass fraction of phloridin into the reaction tank according to the ratio of phloridin-containing raw material to water mass ratio of 1:10. Heating to 45°C, adding the mixed enzyme of cellulose compound enzyme and pectin compound enzyme, the mass ratio of mixed enzyme and phloridin raw material is 1:10, and the mass ratio of cellulose compound enzyme and pectin compound enzyme is 1:1 , 45°C for 10 hours for enzymatic hydrolysis; every 0.5 hours, nitrogen gas is continuously introduced from the bottom of the solution for 1 minute to obtain an enzymatic hydrolysis feed solution; the obtained enzymatic hydrolysis feed liquid is heated to 75°C and inactivated for 10 minutes; a cloth bag centrifuge is used Solid-liquid separation is carried out to obtain wet crystals of phloretin, and dry powdered phloretin products are obtained after drying. The conver...

Embodiment 2

[0038] Add a concentration of 0.5% ethanol aqueous solution to the reaction tank, use hydrochloric acid to adjust the pH value to 5.5, and make the dry powder containing 92.5% mass fraction phlorizin according to the ratio of phloridin-containing raw material to ethanol mass ratio of 1:40 Add to reaction tank. Heating to 55°C, adding the mixed enzyme of cellulose compound enzyme and pectin compound enzyme, the mass ratio of mixed enzyme and phloridin raw material is 1:40, and the mass ratio of cellulose compound enzyme and pectin compound enzyme is 1:100 , 55 ℃ heat preservation enzymolysis for 96 hours; every 2 hours from the bottom of the solution for 5 minutes to continuously pass nitrogen gas to obtain the enzymolysis feed solution; heat the obtained enzymolysis feed solution to 100 ℃, inactivate for 45 minutes; use suction filtration irrigation Solid-liquid separation is carried out to obtain wet crystals of phloretin, and dry powdered phloretin products are obtained afte...

Embodiment 3

[0040] Add a concentration of 5% ethanol aqueous solution to the reaction tank, use hydrochloric acid to adjust the pH value to 4.5, and add the dry powder containing 99% mass fraction of phlorizin according to the ratio of phloridin-containing raw material to ethanol mass ratio of 1:25 in the reaction tank. Heat to 52°C, add the mixed enzyme of cellulose compound enzyme and pectin compound enzyme, the mass ratio of mixed enzyme to phloridin raw material is 1:25, the mass ratio of cellulose compound enzyme and pectin compound enzyme is 1:2 , 52 ℃ heat preservation enzymolysis for 20 hours; every 1 hour from the bottom of the solution into the nitrogen for 3 minutes to obtain the enzymolysis feed solution; the obtained enzymolysis feed solution was heated to 80 ℃, inactivated for 30 minutes; plate and frame press The filter is used for solid-liquid separation to obtain wet crystals of phloretin, which are then dried to obtain dry powder phloretin products. The conversion rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com