LiNbO3/PAN compound nanofiber electret anti-haze window screening and preparation method thereof

A technology of composite nanofibers and electrets, applied in separation methods, fiber treatment, fiber chemical characteristics, etc., can solve problems such as haze hazards, and achieve long charging time, good filtration effect, and increase filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

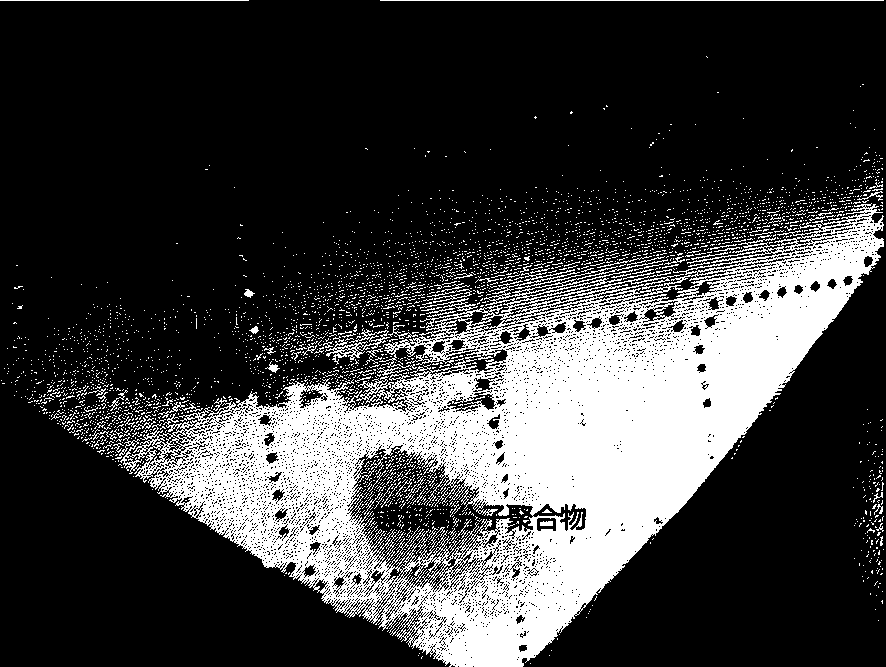

[0032] A LiNbO 3 / PAN composite nanofiber electret anti-haze window screen, including three-layer fiber film, the three-layer fiber film includes a core layer, a base and an upper layer, and the core layer is LiNbO 3 / PAN composite nanofiber, the base is a 500-mesh silver-plated polymer network structure, and the upper layer is a 50-mesh black polyester non-woven fabric, LiNbO 3 / PAN composite nanofibers adhered to silver-coated polymer network by electrospinning to obtain LiNbO 3 Silver-plated network structure of / PAN composite nanofibers with adhered LiNbO 3 The silver-plated network structure of / PAN composite nanofibers is ultrasonically bonded to the black polyester nonwoven fabric.

[0033] The LiNbO 3 / PAN composite nanofibers made of LiNbO 3 Composite of nanocrystals and PAN nanofibers. LiNbO 3 The nano-crystal particles have a single-domain ferroelectric phase single-crystal structure. The LiNbO 3 Nanocrystalline particle size is 20-50 nm, LiNbO 3 / PAN compo...

Embodiment 2

[0042] A LiNbO 3 / PAN composite nanofiber electret anti-haze window screen, including three-layer fiber film, the three-layer fiber film includes a core layer, a base and an upper layer, and the core layer is LiNbO 3 / PAN composite nanofiber, the base is 550-mesh silver-plated polymer network structure, the upper layer is 80-mesh black polyester non-woven fabric, LiNbO 3 / PAN composite nanofibers adhered to silver-coated polymer network by electrospinning to obtain LiNbO 3 Silver-plated network structure of / PAN composite nanofibers with adhered LiNbO 3 The silver-plated network structure of / PAN composite nanofibers is ultrasonically bonded to the black polyester nonwoven fabric.

[0043] A LiNbO 3 / PAN composite nanofiber electret anti-haze window screen preparation method, including the following steps: (1) preparation of LiNbO 3 Nanocrystal: comprise the following steps: a, will weigh Li 2 CO 3 and Nb 2 o 5 Pour into a beaker to prepare Li 2 CO 3 and Nb 2 o 5 m...

Embodiment 3

[0051] A LiNbO 3 / PAN composite nanofiber electret anti-haze window screen, including three-layer fiber film, the three-layer fiber film includes a core layer, a base and an upper layer, and the core layer is LiNbO 3 / PAN composite nanofiber, the base is a 600-mesh silver-plated polymer network structure, and the upper layer is a 120-mesh black polyester non-woven fabric, LiNbO 3 / PAN composite nanofibers adhered to silver-coated polymer network by electrospinning to obtain LiNbO 3 Silver-plated network structure of / PAN composite nanofibers with adhered LiNbO 3 The silver-plated network structure of / PAN composite nanofibers is ultrasonically bonded to the black polyester nonwoven fabric.

[0052] The LiNbO 3 / PAN composite nanofiber electret anti-haze window screen preparation method, including the following steps: (1) preparation of LiNbO 3 Nanocrystal: comprise the following steps: a, will weigh Li 2 CO 3 and Nb 2 o 5 Pour into a beaker to prepare Li 2 CO 3 and N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com