Pyridine wastewater purification treatment method

A wastewater purification and treatment method technology, applied in the direction of water/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of high cost, poor purification effect, poor degradation performance, etc., and achieve improved oxidation efficiency , reduce the negative impact, the effect of easy engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

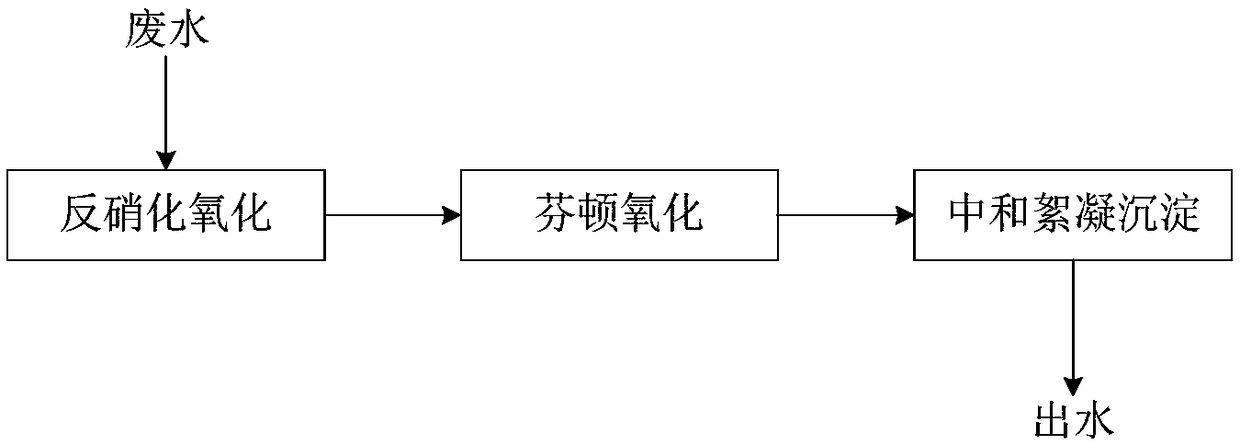

Method used

Image

Examples

Embodiment 1

[0035] A kind of wastewater containing pyridine and 3-picoline, pH value is 6.5, light yellow, COD content is 3000mg / L, total nitrogen is 400mg / L, pyridine content is 200mg / L, 3-picoline content is 20mg / L.

[0036] The specific processing steps are as follows:

[0037](1) Denitrification and oxidation: Based on the quality of wastewater, add 3% potassium nitrate, adjust the C / N ratio of wastewater to 5, add sodium carbonate, adjust the pH to 6.5, stir and mix, and the wastewater enters the activated sludge The denitrification device, the amount of sludge added to each liter of wastewater is 5g, stay for 16h, and denitrification treatment solution is obtained after the end; the water quality test and analysis of the obtained denitrification treatment solution, the measured COD is 2100mg / L, pyridine 50mg / L , 3-picoline 15mg / L.

[0038] (2) Fenton oxidation: add sodium carbonate to adjust the pH of the denitrification treatment solution to be 3, the quality of the denitrificat...

Embodiment 2

[0044] A kind of wastewater containing pyridine, pH value is 6.5, light yellow, COD content is 3000mg / L, total nitrogen is 400mg / L, pyridine content is 200mg / L, 3-picoline content is 20mg / L. .

[0045] The specific processing steps are as follows:

[0046] (1) Denitrification and oxidation: Based on the quality of wastewater, add 1.5% sodium nitrate, adjust the C / N ratio of wastewater to 10, add sulfuric acid, adjust the pH to 7.5, stir and mix, and the wastewater enters the anaerobic sludge The denitrification device, the amount of sludge added to each liter of wastewater is 20g, stay for 24h, after the end of the denitrification treatment solution; the water quality test and analysis of the denitrification treatment solution obtained, the measured COD is 1800mg / L, pyridine 45mg / L , 3-picoline 10mg / L.

[0047] (2) Fenton oxidation: adjust the pH of the denitrification treatment solution to be 5, take the denitrification effluent quality as a benchmark, add 0.6% hydrogen per...

Embodiment 3

[0053] A kind of wastewater containing pyridine and 3-picoline, pH value is 6.5, light yellow, COD content is 3000mg / L, total nitrogen is 400mg / L, pyridine content is 200mg / L, 3-picoline content is 20mg / L.

[0054] The specific processing steps are as follows:

[0055] (1) Denitrification and oxidation: Based on the quality of wastewater, add 2.3% calcium nitrate, adjust the C / N ratio of wastewater to 8, add sodium carbonate, adjust the pH to 7, stir and mix, and the wastewater enters the denitrifying bacteria agent ( denitrification) anaerobic sludge denitrification device, the amount of sludge added per liter of waste water is 12g and stays for 20h, and the denitrification treatment solution is obtained after the end; the water quality test and analysis of the obtained denitrification treatment solution shows that the COD is 2000mg / L, pyridine 55mg / L, 3-picoline 18mg / L.

[0056] (2) Fenton oxidation: adjust the pH of the denitrification treatment solution to 4, take th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com