Concrete containing modified fibers and preparation method thereof

A modified fiber and concrete technology, applied in the field of concrete, can solve the problems of low stability, short life, poor alkali resistance of bamboo fiber, etc., and achieve the effects of low surface free energy, extended service life, and excellent light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]Embodiment 1: A kind of concrete containing modified fibers, the composition and weight ratio of its raw materials are shown in Table 1. Among them, the cement is ordinary Portland cement with a strength grade of P.O42.5; the water reducer is a standard high-performance water reducer purchased from Kezhijie New Material Group Co., Ltd.; the fly ash is purchased from Hou For the Class II (Class F) fly ash of Shishi Power Plant, the ore powder is S95 ore powder purchased from Sangang Group (Longhai) Mine Micro Powder Co., Ltd., and the silica fume is purchased from Xiamen Yulin Technology Co., Ltd.

[0055] The modified polyacrylonitrile fiber includes polyacrylonitrile fiber and a corrosion-resistant coating sprayed on the surface of the polyacrylonitrile fiber. The thickness of the corrosion-resistant coating is 40-50 μm, and the length of the modified polyacrylonitrile fiber is 8 ± 1mm. The diameter is 20 μm.

[0056] The raw material of corrosion-resistant coating com...

Embodiment 2-5

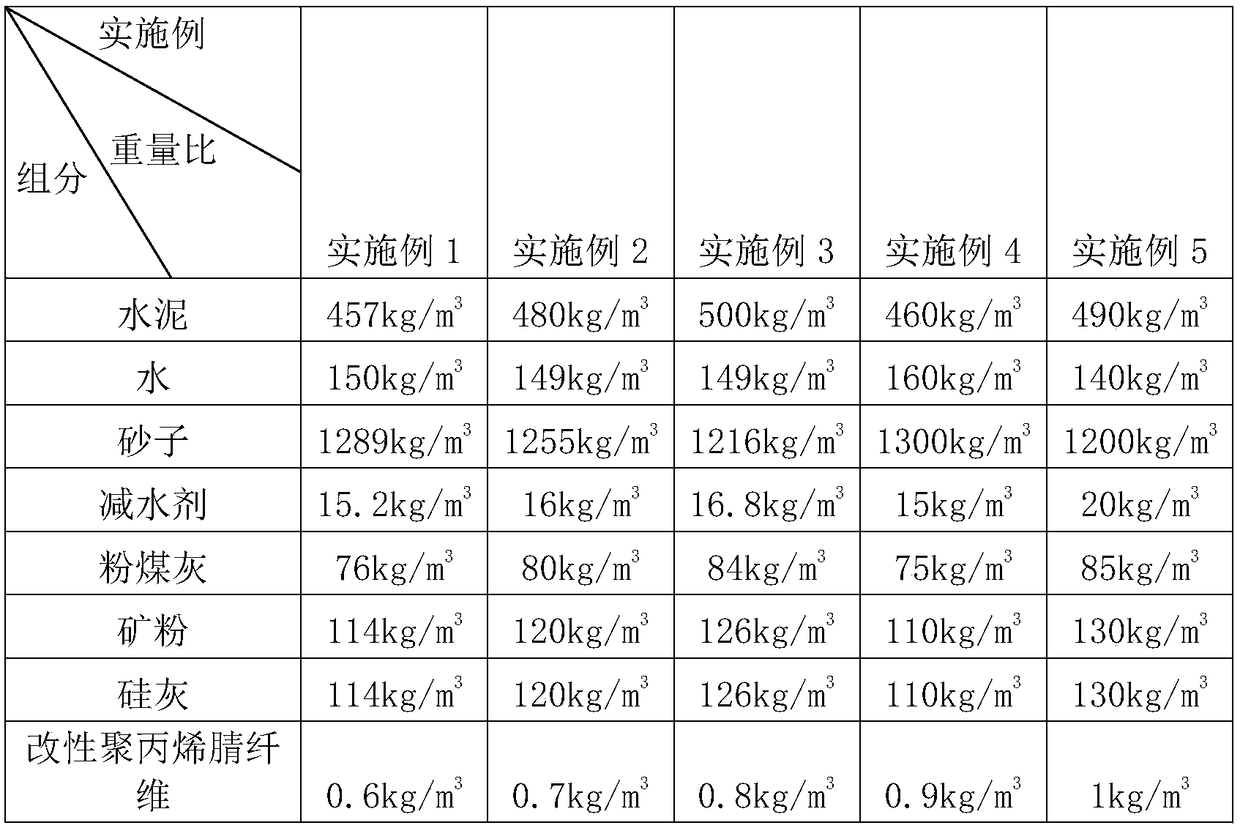

[0074] Example 2-5: A concrete containing modified fibers, the difference from Example 1 lies in the composition and weight ratio of its raw materials as shown in Table 1.

[0075] The composition of raw material and its weight ratio in table 1 embodiment 1-5

[0076]

Embodiment 6

[0077] Example 6: A concrete containing modified fibers, the difference from Example 1 is that the thickness of the corrosion-resistant coating is 45 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com