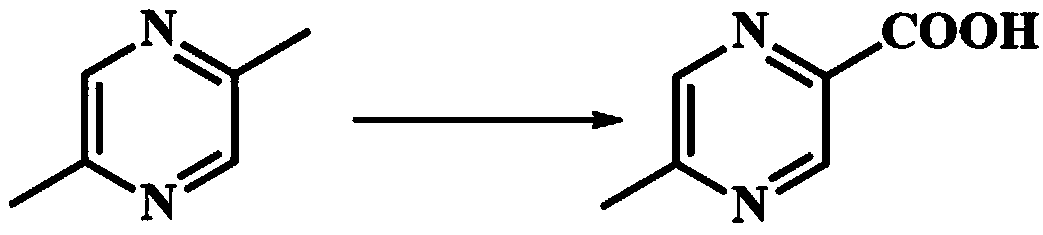

Method for preparing 5-methylpyrazine-2-carboxylic acid by catalytic oxidation

A methylpyrazine, catalytic oxidation technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the difficult synthesis and oxidation synthesis of 5-methyl porphyrin catalysts Pyrazine-2-carboxylic acid, high price and other problems, to achieve the effect of easy industrial scale production, easy control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing 5-methylpyrazine-2-carboxylic acid by catalytic oxidation. At first, diatomite, manganese chloride, sodium tungstate, cobalt nitrate, and distilled water are added to the reactor according to the mass ratio of the following elements, silicon Alite: Mn: W: Co: H 2 O=1:0.03:0.03:0.05:50, stir magnetically at room temperature to disperse and absorb evenly, then remove water by evaporation, add liquid silica sol with 5% of the total mass of the solid sample and knead it into small particles of 1-2mm The samples were placed in a muffle furnace and calcined in an air atmosphere at 550°C for 5 hours to obtain Mn-W-Co / diatomaceous earth supported catalyst particles. Fill 10g of Mn-W-Co / diatomaceous earth catalyst particles into the fixed-bed microreactor reaction tube, raise the temperature of the reactor to 240°C, and use high-temperature steam to feed 2,5-dimethylpyrazine at 10ml / Introduce bubbling into the fixed bed reaction tube in 1 minute, and inj...

Embodiment 2

[0026] A method for preparing 5-methylpyrazine-2-carboxylic acid by catalytic oxidation. At first, diatomite, manganese chloride, sodium tungstate, cobalt nitrate, and distilled water are added to the reactor according to the mass ratio of the following elements, silicon Alite: Mn: W: Co: H 2 O=1:0.05:0.05:0.07:50, stir magnetically at room temperature to disperse and absorb evenly, then remove water by evaporation, add liquid silica sol with 5% of the total mass of the solid sample and knead it into small particles of 1-2mm The samples were placed in a muffle furnace and calcined in an air atmosphere at 600°C for 4 hours to obtain Mn-W-Co / diatomaceous earth supported catalyst particles. Fill 10g of Mn-W-Co / diatomite catalyst particles into the reaction tube of the fixed-bed microreactor, raise the temperature of the reactor to 300°C, and use high-temperature steam to feed 2,5-dimethylpyrazine at 10ml / Introduce bubbling into the fixed bed reaction tube in 1 minute, and injec...

Embodiment 3

[0028] A method for preparing 5-methylpyrazine-2-carboxylic acid by catalytic oxidation. At first, diatomite, manganese chloride, sodium tungstate, cobalt nitrate, and distilled water are added to the reactor according to the mass ratio of the following elements, silicon Alite: Mn: W: Co: H 2 O=1:0.07:0.06:0.09:50, stir magnetically at room temperature to disperse and absorb evenly, then remove water by evaporation, add liquid silica sol with 5% of the total mass of the solid sample and knead it into small particles of 1-2mm The samples were placed in a muffle furnace and calcined in an air atmosphere at 660°C for 5 hours to obtain Mn-W-Co / diatomaceous earth supported catalyst particles. Fill 10g of Mn-W-Co / diatomite catalyst particles into the fixed-bed microreactor reaction tube, raise the temperature of the reactor to 320°C, and use high-temperature steam to feed 2,5-dimethylpyrazine at 10ml / Introduce bubbling into the fixed bed reaction tube in 1 minute, and inject oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com