Preparation method of 3,3,3-trifluoropropylene carbonate

A technology of trifluoropropylene carbonate and trifluoropropylene oxide is applied in the field of synthesis of fluoropropylene carbonate, which can solve the problems of corrosive safety hazards, high price of trifluoropropylene oxide, easy deactivation, etc. The effect of low cost, low raw material cost and high route yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

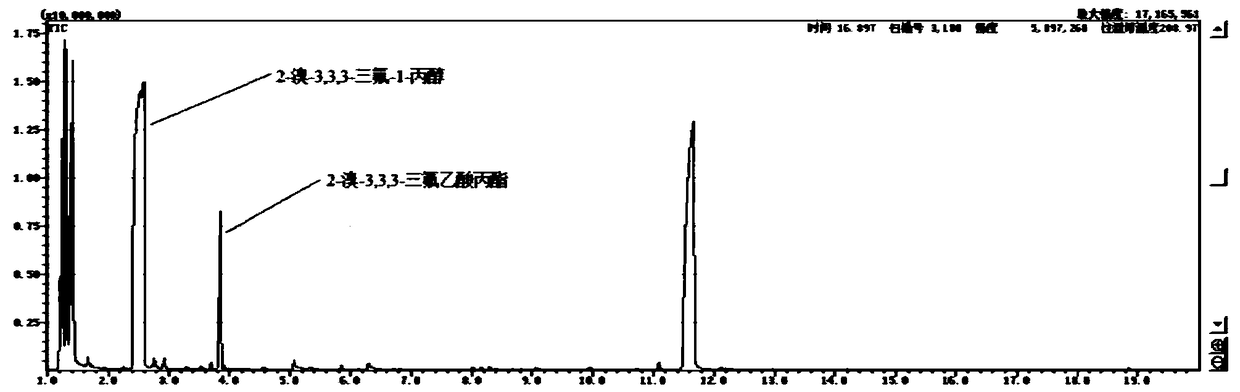

[0068] 1. Synthesis of 2-bromo-3,3,3-trifluoro-1-propanol:

[0069] Use excess trifluoropropene to pass into the mixture of 8000mg 20% oleum and 1600mg bromine, keep the temperature at 12-22°C, stop the aeration until the reddish brown of bromine in the flask disappears, add to the mixed solution 15ml of acetic acid was heated at 95°C for 1h. The product was extracted and washed to obtain propyl 2-bromo-3,3,3-trifluoroacetate. After analysis by chromatography-mass spectrometry, the yield was 76.14%, and the selectivity was 95%. Add 35.8 mg of concentrated sulfuric acid and 488 mg of methanol to 1790 mg of 2-bromo-3,3,3-trifluoroacetic acid propyl ester, and after reflux in an oil bath at 70°C for 4 hours, distill off excess methanol and Ethyl formate to give 2-bromo-3,3,3-trifluoro-1-propanol. After chromatographic mass spectrometry analysis, the productive rate is 92.58%, see image 3 .

[0070] 2. Synthesis of 1,1,1-trifluoro-2,3-epoxypropane:

[0071] Add 733.2mg of...

Embodiment 2

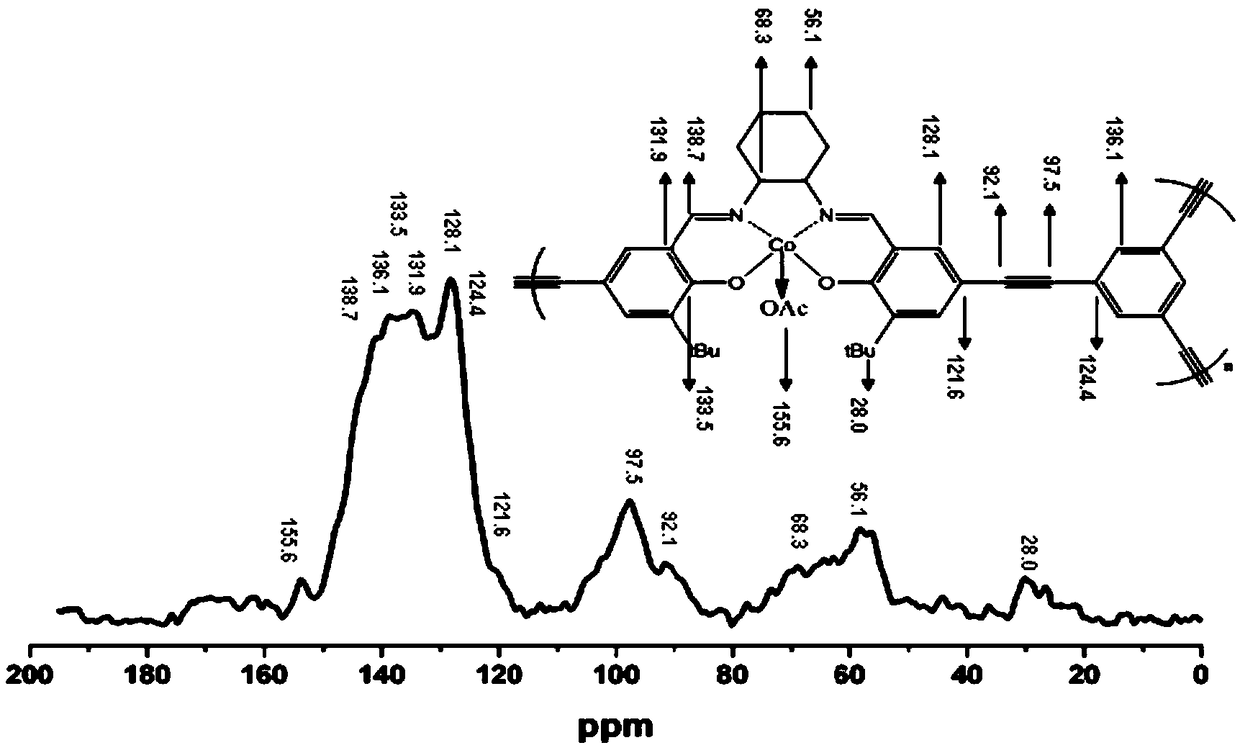

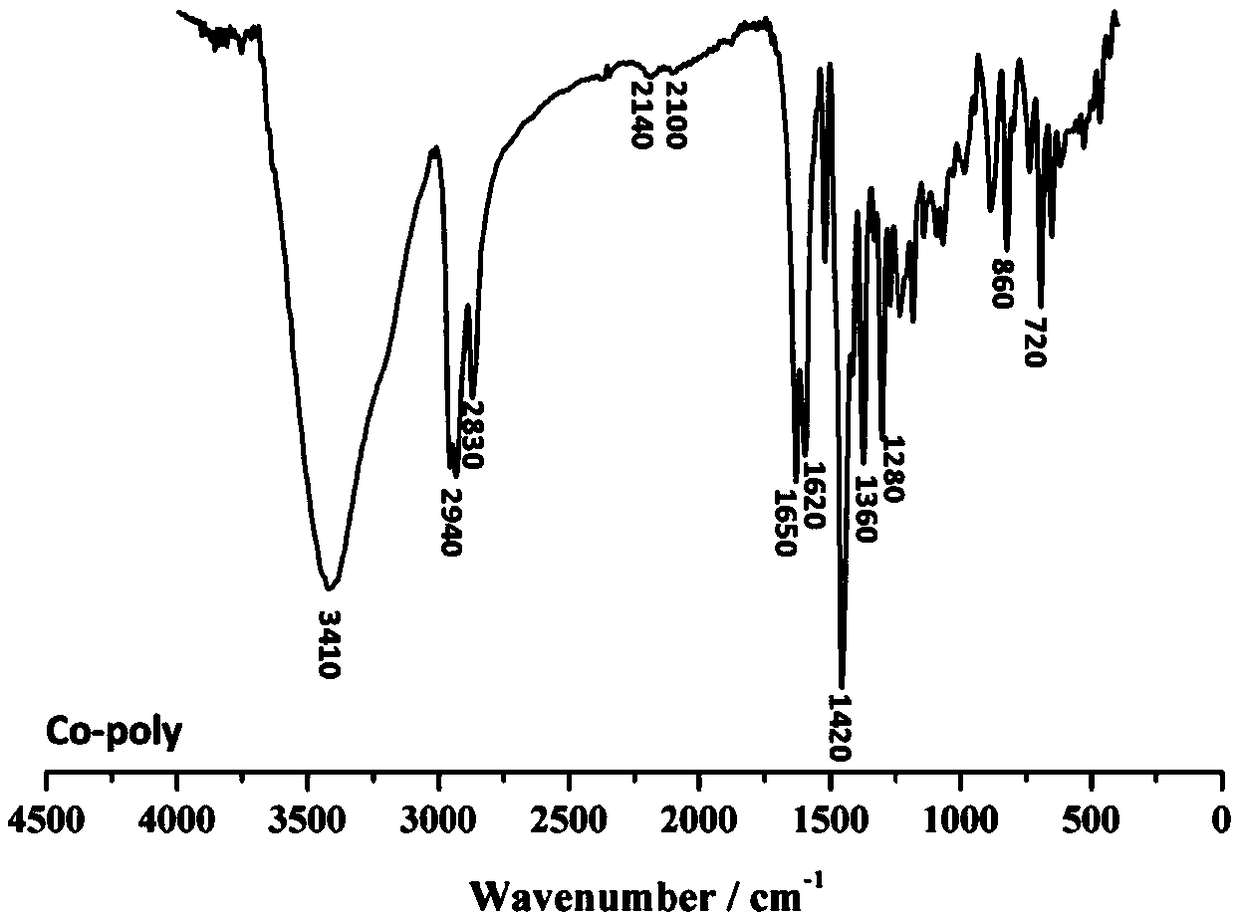

[0073] Synthesis of Metal Conjugated Microporous Polymer Complex Catalysts Co-CMP and Co-poly.

[0074] 1. Synthesis of Co-CMP:

[0075] 1.1, with 9.98mmol 3-tert-butyl-2-hydroxybenzaldehyde and 10.3mmol bromine as raw materials, after the reaction solution was stirred for 2 to 3 hours, purified to obtain 5-bromo-3-tert-butyl-2-hydroxybenzaldehyde, the 8.0mmol 5-bromo-3-tert-butyl-2-hydroxybenzaldehyde was dissolved in tetrahydrofuran to form a solution, and the solution was added dropwise to 4.0mmol (R,R)-1,2-diaminocyclohexane solution, Under the condition of 80°C, the reaction mixture was continuously stirred and refluxed for 4-5 hours to obtain the Salen-I ligand through purification.

[0076] 1.2. Add 0.675mmol of Salen-I ligand into the three-necked flask, then seal it, and treat it under anaerobic conditions. Under the protection of argon, add 10ml of anhydrous toluene, stir, and wait until the solid matter is completely dissolved , continue to stir, add 0.96 mmol of ...

Embodiment 3

[0088] Synthesis of 3,3,3-trifluoropropene carbonate:

[0089] 3.1. Polymer catalyst Co-CMP catalyzes the reaction of carbon dioxide with 1,1,1-trifluoro-2,3-propylene oxide: the polymer catalyst Co-CMP, tetrabutylammonium bromide (TBAB) and 1 , 1,1-trifluoro-2,3-epoxypropane is fed according to the mass ratio of 1:5.8:28-56, the carbon dioxide pressure is 0.1-3.0MPa, the temperature is 25-100°C and the reaction is stirred for 1-48h to obtain 3,3,3-Trifluoropropene carbonate. The results are shown in the table below:

[0090]

[0091] As can be seen from the table, when the reaction temperature is increased and the pressure is increased, the yield can reach 97%.

[0092] 3.2. The polymer catalyst Co-poly catalyzes the reaction of carbon dioxide and 1,1,1-trifluoro-2,3-propylene oxide: the polymer catalyst Co-poly and 1,1,1-trifluoro-2, 3-Propylene oxide is fed in a mass ratio of 1:28-56, the carbon dioxide pressure is 0.1-3.0MPa, and the temperature is 25-100°C, stirred an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com