Environment-friendly asphalt and production process thereof

A modified asphalt and environmental protection technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of limited improvement range and insignificant overall improvement effect of asphalt performance, so as to improve the anti-rutting ability, and the raw materials are non-toxic and harmless. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

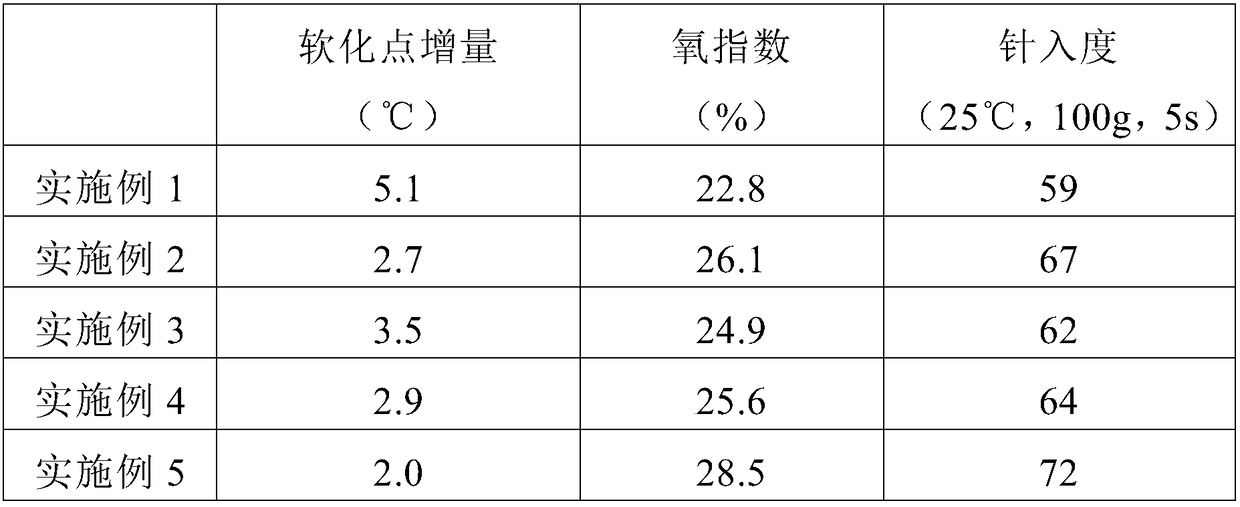

Examples

Embodiment 1

[0026] Environmentally-friendly modified asphalt, in parts by weight, is prepared from the following raw materials: 2 parts of styrene-butadiene rubber, 95 parts of petroleum asphalt, 0.9 parts of polyphosphoric acid, 0.2 parts of crosslinking agent, 2 parts of phosphorus-containing flame retardant, poly 1.2 parts of vinyl wax, 5 parts of stone powder, 0.2 parts of nonylphenol, 0.35 parts of dispersant, and 0.2 parts of diphenylamine.

[0027] The crosslinking agent is isopropyl titanate.

[0028] The phosphorus-containing flame retardant is a cellulose-based nitrogen-phosphorus flame retardant.

[0029] The dispersant is sodium hexametaphosphate.

[0030] The stone powder is a modified spodumene powder.

[0031] The modified spodumene powder is prepared by the following method: add 20 g of spodumene powder to 200 mL of deionized water, stir at 300 r / min for 15 min to obtain a uniform dispersion, and adjust the pH with 0.1 mol / L dilute hydrochloric acid to 2. Ultrasonic tre...

Embodiment 2

[0037] Environmentally-friendly modified asphalt, in parts by weight, is prepared from the following raw materials: 2 parts of styrene-butadiene rubber, 95 parts of petroleum asphalt, 0.9 parts of polyphosphoric acid, 0.2 parts of crosslinking agent, 2 parts of phosphorus-containing flame retardant, poly 1.2 parts of vinyl wax, 5 parts of stone powder, 0.2 parts of nonylphenol, 0.35 parts of dispersant, and 0.2 parts of diphenylamine.

[0038] The crosslinking agent is isopropyl titanate.

[0039] The phosphorus-containing flame retardant is a cellulose-based nitrogen-phosphorus flame retardant.

[0040] The dispersant is sodium hexametaphosphate.

[0041] The stone powder is spodumene powder.

[0042] The production process of the above-mentioned environmentally friendly modified asphalt comprises the following steps:

[0043]S1. Heat the asphalt at 155°C to complete melting, add styrene-butadiene rubber, polyethylene wax, stone powder, nonylphenol, dispersant, diphenylami...

Embodiment 3

[0047] Environmentally friendly modified asphalt, calculated in parts by weight, is prepared from the following raw materials: 2 parts of styrene-butadiene rubber, 95 parts of petroleum asphalt, 0.9 parts of polyphosphoric acid, 0.2 parts of crosslinking agent, 2 parts of phosphorus-containing flame retardant, 1.2 parts of vinyl wax, 5 parts of stone powder, 0.2 part of nonylphenol, 0.35 part of dispersant, and 0.2 part of diphenylamine.

[0048] The crosslinking agent is isopropyl titanate.

[0049] The phosphorus-containing flame retardant is a cellulose-based nitrogen-phosphorus flame retardant.

[0050] The dispersant is sodium hexametaphosphate.

[0051] The stone powder is a modified product of spodumene powder.

[0052] The spodumene powder modified product is prepared by the following method: adding 20 g of spodumene powder to 200 mL of deionized water, stirring at a rotational speed of 300 r / min for 15 min to obtain a uniform dispersion, and adjusting the pH to be 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com