Preparation method of heat-conducting hot melt adhesive

A hot-melt adhesive and reaction technology, applied in the direction of heat exchange materials, chemical instruments and methods, adhesives, etc., can solve the problems of poor thermal conductivity of hot-melt adhesives, and ensure the uniformity and dispersion of acidification, good thermal conductivity and stability. The effect of reducing the temperature potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

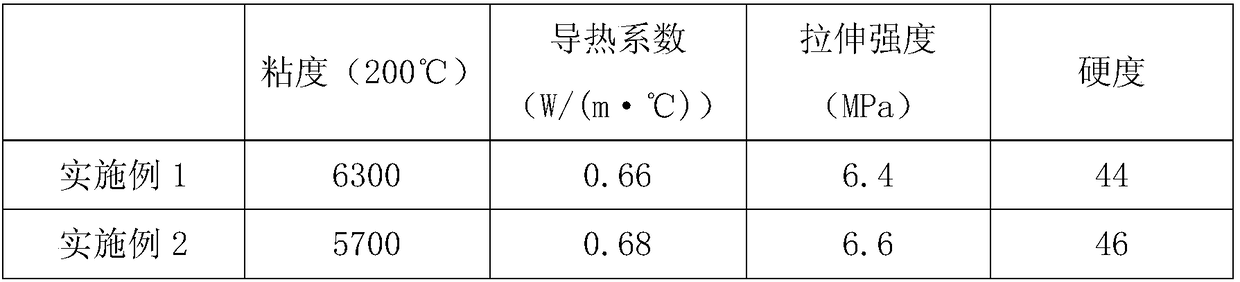

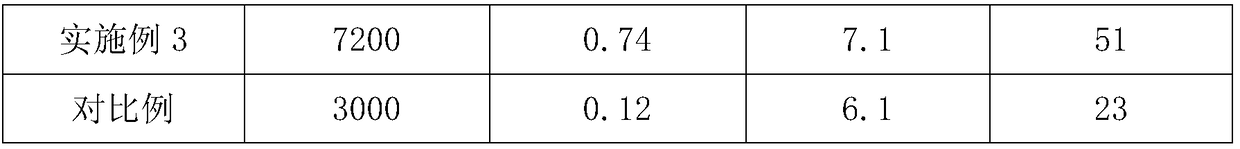

Examples

Embodiment 1

[0030] A preparation method of thermally conductive hot melt adhesive, characterized in that: the preparation method comprises the following steps,

[0031] Step 1, adding ethylene-vinyl acetate copolymer and terpene resin into ethanol aqueous solution, ultrasonically reacting for 10 minutes, and distilling under reduced pressure until viscous liquid is formed;

[0032] Step 2, putting graphene into hydrochloric acid solution, ultrasonically reacting for 1 hour, and microwave reacting for 0.5 hour, to obtain acidified graphene liquid;

[0033] Step 3, subject the acidified graphene liquid to a constant temperature evaporation reaction for 10 minutes, add heat transfer oil and dispersant after cooling, and stir evenly to obtain a heat transfer mixture;

[0034] Step 4: Add the initiator to the viscous liquid, stir evenly, then slowly add the heat-conducting mixed liquid dropwise, and react with microwave until the addition is completed, and stand for 1 hour under constant press...

Embodiment 2

[0046] A preparation method of thermally conductive hot melt adhesive, characterized in that: the preparation method comprises the following steps,

[0047] Step 1, adding ethylene-vinyl acetate copolymer and terpene resin into ethanol aqueous solution, ultrasonically reacting for 15 minutes, and distilling under reduced pressure until viscous liquid is formed;

[0048] Step 2, putting graphene into hydrochloric acid solution, ultrasonically reacting for 3 hours, and microwave reacting for 1.5 hours, to obtain acidified graphene liquid;

[0049] Step 3, subject the acidified graphene liquid to a constant temperature evaporation reaction for 20 minutes, add heat transfer oil and dispersant after cooling, and stir evenly to obtain a heat transfer mixture;

[0050]Step 4: Add the initiator to the viscous liquid, stir evenly, then slowly add the heat-conducting mixed liquid dropwise, and react with microwaves until the addition is completed, and stand for 3 hours under constant pr...

Embodiment 3

[0062] A preparation method of thermally conductive hot melt adhesive, characterized in that: the preparation method comprises the following steps,

[0063] Step 1, adding ethylene-vinyl acetate copolymer and terpene resin into ethanol aqueous solution, ultrasonically reacting for 13 minutes, and distilling under reduced pressure until viscous liquid is formed;

[0064] Step 2, putting graphene into hydrochloric acid solution, ultrasonically reacting for 2 hours, and microwave reacting for 1 hour, to obtain acidified graphene liquid;

[0065] Step 3, subject the acidified graphene liquid to a constant temperature evaporation reaction for 15 minutes, add heat transfer oil and dispersant after cooling, and stir evenly to obtain a heat transfer mixture;

[0066] Step 4: Add the initiator to the viscous liquid, stir evenly, then slowly add the heat-conducting mixed liquid dropwise, and react with microwave until the addition is completed, and stand for 2 hours under constant press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com