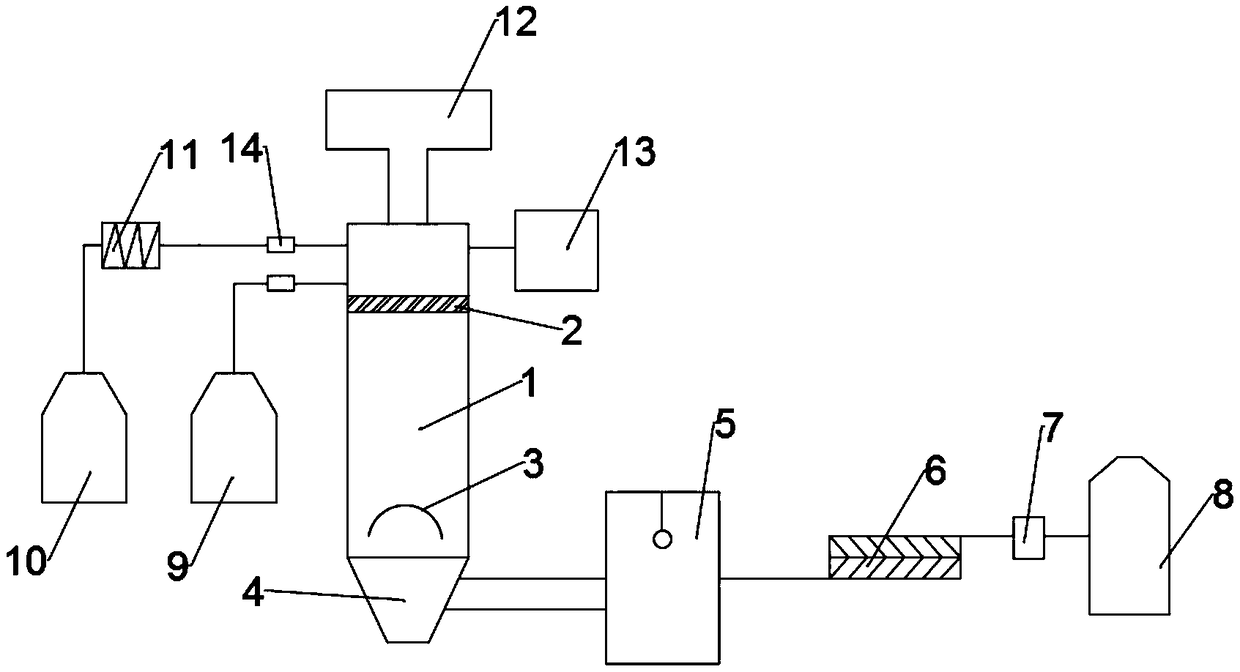

Method for preparing biomass gasified syngas and equipment thereof

A technology for synthesis gas and biomass, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry, etc., can solve the problems that need to be further improved, and achieve the effect of improving gasification efficiency, simple process and low cost.

- Summary

- Abstract

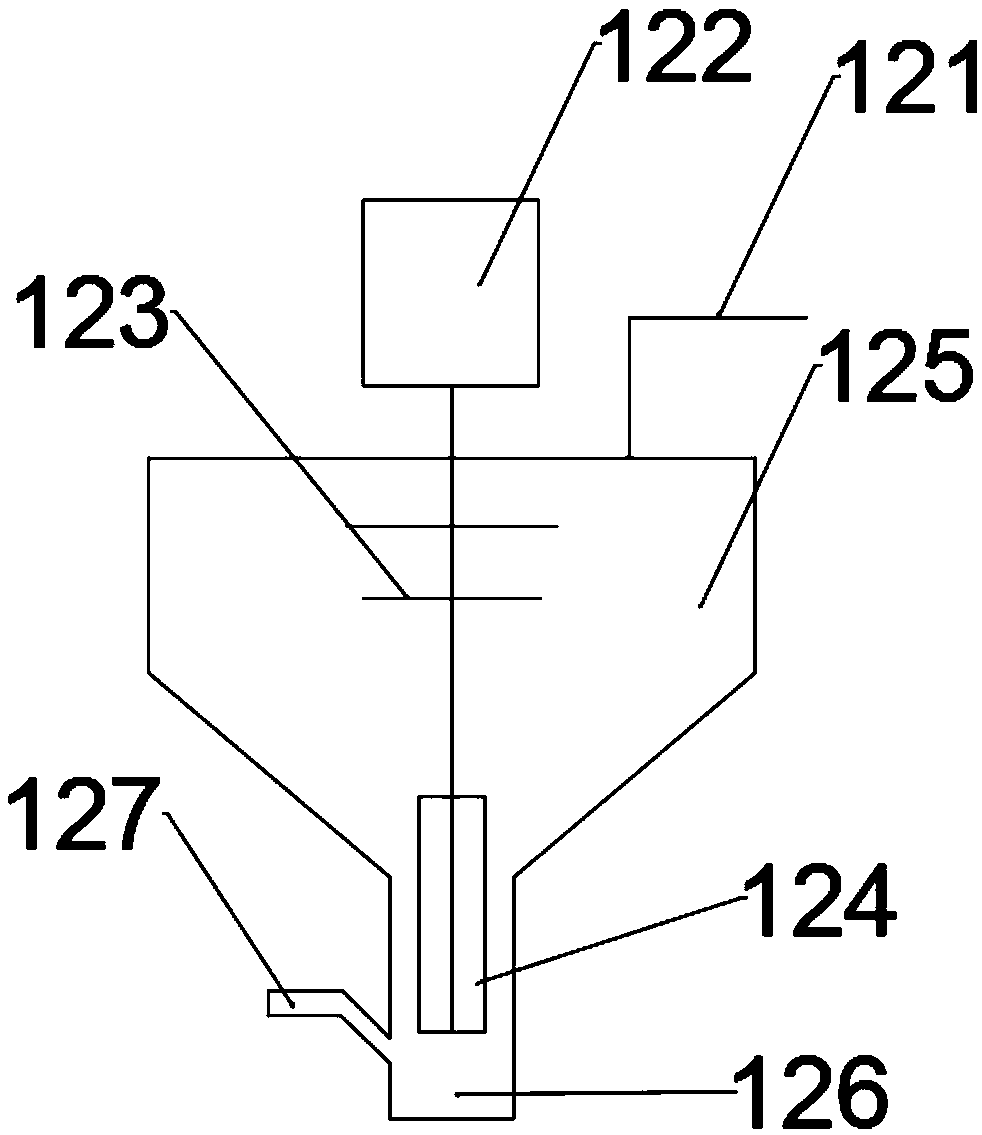

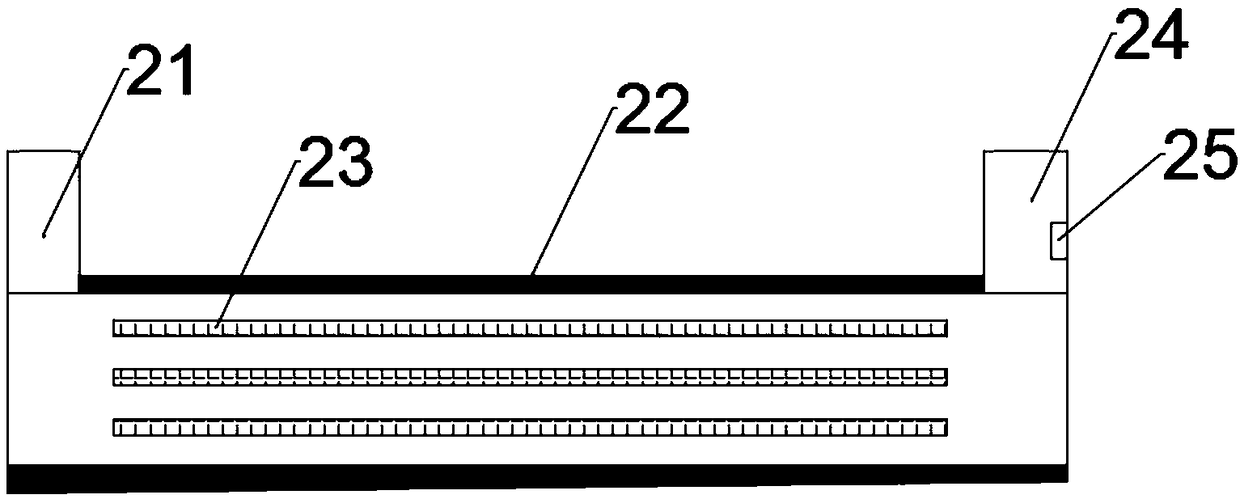

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing biomass gasification synthesis gas, comprising the following steps:

[0032] (1) In parts by weight, 12 parts of neodymium chloride and 8 parts of promethium chloride are added to 105 parts of water, after mixing and stirring evenly, 30 parts of sodium erucate are added thereto, and the temperature of the mixture is raised to 90°C, After heat preservation treatment for 2 hours, the gasification aid was obtained;

[0033] (2) After drying the corn stalks, add rice husks 0.5 times its weight to it, mix evenly, and crush until the average particle size is 60 mesh to obtain biomass raw materials. The temperature during drying treatment is 75°C , the drying time is 100min;

[0034] (3) In parts by weight, mix 80 parts of biomass raw materials, 2 parts of gasification additives, and 0.6 parts of potassium fluotitanate evenly, then add them into an oven, and dry them to obtain gasification raw materials. The temperature during treatment is 75°C, and th...

Embodiment 2

[0038] A method for producing biomass gasification synthesis gas, comprising the following steps:

[0039] (1) In parts by weight, 13 parts of neodymium chloride and 9 parts of promethium chloride were added to 110 parts of water, after mixing and stirring evenly, 32 parts of sodium erucate were added thereto, and the temperature of the mixture was raised to 92°C, After heat preservation treatment for 2.5 hours, the gasification aid was obtained;

[0040](2) After drying the corn stalks, add rice husks 0.6 times its weight to it, mix them evenly, and crush them until the average particle size is 70 mesh to obtain biomass raw materials. The temperature during drying treatment is 76°C , the drying time is 102min;

[0041] (3) In parts by weight, mix 82 parts of biomass raw materials, 3 parts of gasification additives, and 0.7 parts of potassium fluotitanate evenly, then add them into an oven, and dry them to obtain gasification raw materials, and dry them The temperature durin...

Embodiment 3

[0045] A method for preparing biomass gasification synthesis gas, comprising the following steps:

[0046] (1) In parts by weight, 15 parts of neodymium chloride and 11 parts of promethium chloride were added to 115 parts of water, after mixing and stirring evenly, 34 parts of sodium erucate were added thereto, and the temperature of the mixture was raised to 94°C. After heat preservation treatment for 3 hours, the gasification aid was obtained;

[0047] (2) After drying the corn stalks, add rice husks 0.7 times its weight to it, mix well, and crush until the average particle size is 80 mesh to obtain biomass raw materials. The temperature during drying treatment is 78°C , the drying time is 115min;

[0048] (3) In parts by weight, after mixing 84 parts of biomass raw materials, 4 parts of gasification aids, and 0.7 parts of potassium fluotitanate evenly, add them to an oven, and dry them to obtain gasification raw materials, and dry them The temperature during processing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com