High-voltage vacuum circuit breaker assembly process

A vacuum circuit breaker and assembly process technology, which is applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve the problems of fuzzy division of high and low voltage boundaries, unguaranteed assembly quality, and low assembly efficiency, so as to improve production Efficiency, reduction of manufacturing costs, and improvement of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

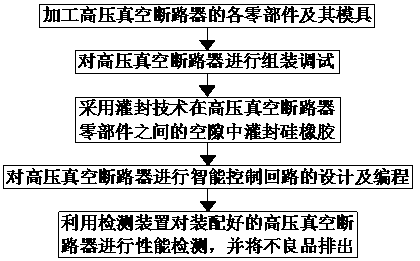

Method used

Image

Examples

Embodiment 1

[0026] First process the parts and molds of the high-voltage vacuum circuit breaker, and the high-voltage vacuum circuit breaker includes vacuum interrupter, solid insulation layer, insulating rod, connecting plate group, opening spring assembly, main shaft, oil buffer, overtravel spring , opening spring, high-voltage modular mechanism and solid-sealed pole, etc., and the high-voltage modular mechanism is a modular splint-type structural unit. Including closing semi-shaft, opening semi-shaft, closing electromagnet, opening electromagnet, overcurrent release, manual energy storage handle, closing spring and energy storage motor; The primary conductive circuit of the vacuum circuit breaker is mainly directly sealed in the special epoxy resin material by the vacuum interrupter to form a main conductive circuit module. The mold is made of ABS resin melted and solidified at high temperature, and the ABS resin is The temperature of the high-voltage vacuum circuit breaker is controll...

Embodiment 2

[0028] First process the parts and molds of the high-voltage vacuum circuit breaker, and the high-voltage vacuum circuit breaker includes vacuum interrupter, solid insulation layer, insulating rod, connecting plate group, opening spring assembly, main shaft, oil buffer, overtravel spring , opening spring, high-voltage modular mechanism and solid-sealed pole, etc., and the high-voltage modular mechanism is a modular splint-type structural unit. Including closing semi-shaft, opening semi-shaft, closing electromagnet, opening electromagnet, overcurrent release, manual energy storage handle, closing spring and energy storage motor; The primary conductive circuit of the vacuum circuit breaker is mainly directly sealed in the special epoxy resin material by the vacuum interrupter to form a main conductive circuit module. The mold is made of ABS resin melted and solidified at high temperature, and the ABS resin is The temperature of the high-voltage vacuum circuit breaker is controll...

Embodiment 3

[0030] First process the parts and molds of the high-voltage vacuum circuit breaker, and the high-voltage vacuum circuit breaker includes vacuum interrupter, solid insulation layer, insulating rod, connecting plate group, opening spring assembly, main shaft, oil buffer, overtravel spring , opening spring, high-voltage modular mechanism and solid-sealed pole, etc., and the high-voltage modular mechanism is a modular splint-type structural unit. Including closing semi-shaft, opening semi-shaft, closing electromagnet, opening electromagnet, overcurrent release, manual energy storage handle, closing spring and energy storage motor; The primary conductive circuit of the vacuum circuit breaker is mainly directly sealed in the special epoxy resin material by the vacuum interrupter to form a main conductive circuit module. The mold is made of ABS resin melted and solidified at high temperature, and the ABS resin is The temperature of the high-voltage vacuum circuit breaker is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com