Pure plant composite formaldehyde and odor cleaning agent and preparation method thereof

A kind of odor removal and composite technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of human body and environment with slight toxicity, slow removal effect, side effects, etc., achieve non-toxic side effects, high efficiency, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

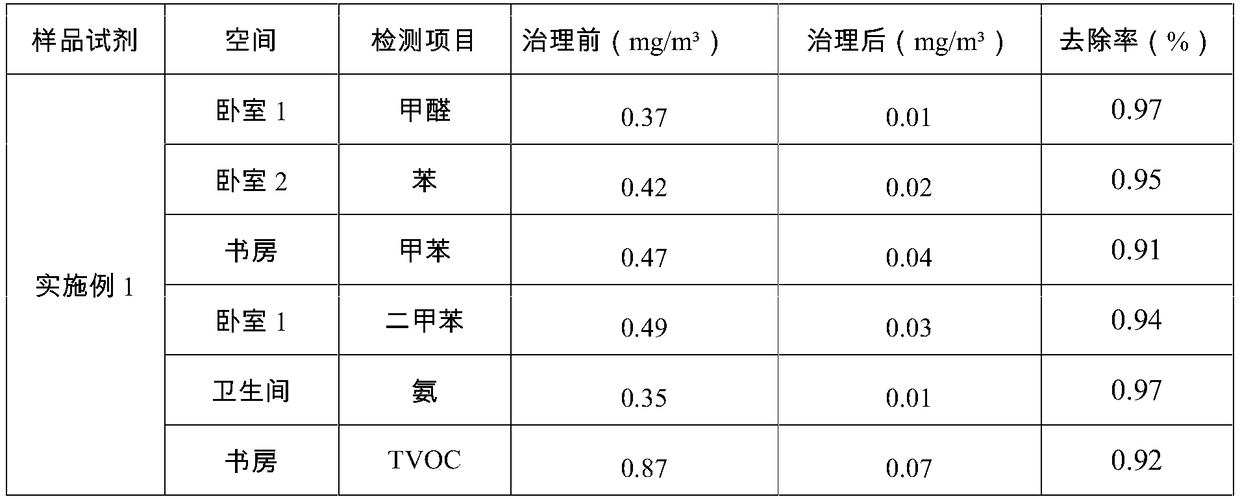

Embodiment 1

[0018] 1. Take the following raw materials in parts by weight: 1 part of jasmine, 1 part of wild chrysanthemum, 1 part of lily, 2 parts of gardenia, 1 part of rose, 2 parts of osmanthus, 1 part of honeysuckle, 2 parts of mint, 2 parts of sweet orange Peel, 1 part grapefruit peel, 1 part lavender, 1 part wintergreen, 1 part pine needle, 3 parts aloe vera, 2 parts sophora flavescens, 2 parts licorice, 2 parts green tea leaves, 2 parts ginkgo biloba, 1 part pepper and 1 part pepper. Crush each group into powder and mix them with a pulverizer, slowly add 40% ethanol (volume ratio), the liquid-to-material ratio is 1:10 (weight ratio), and soak in an environment-sealed container at a temperature of 20°C-35°C for 25 hours; the solution was filtered several times to remove the dregs; the ethanol in the solution was recovered by distillation under reduced pressure to obtain the basic plant extract X.

[0019] 2. Get 10 parts by weight of basic plant extract X, 5 parts of surfactant (so...

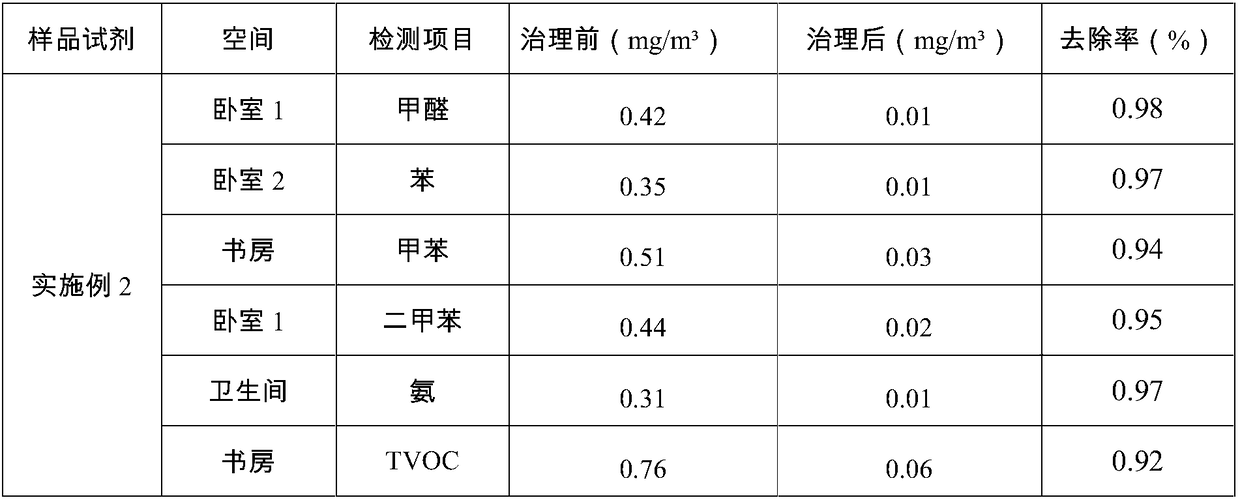

Embodiment 2

[0021] 1. Take the following raw materials in parts by weight: 2 parts of jasmine, 1 part of wild chrysanthemum, 1 part of lily, 2 parts of gardenia, 3 parts of rose, 1 part of osmanthus, 1 part of honeysuckle, 2 parts of mint, 2 parts of sweet orange Peel, 3 parts grapefruit peel, 1 part lavender, 1 part wintergreen, 2 parts pine needles, 4 parts aloe vera, 3 parts sophora flavescens, 2 parts licorice, 3 parts green tea leaves, 3 parts ginkgo biloba, 2 parts hot pepper and 2 parts peppercorns. Crush each group into powder with a pulverizer and mix, slowly add 50% ethanol, the ratio of liquid to material is 1:10, put it in a sealed container with a temperature of 20°C-35°C for 25 hours; filter the solution several times to remove the dregs; the ethanol in the solution was recovered by distillation under reduced pressure to obtain the basic plant extract X.

[0022] 2. Get 10 parts by weight of basic plant extract X, 4 parts of surfactant (sodium cocoyl methyl taurate), 1 part ...

Embodiment 3

[0024] 1. Take the following raw materials in parts by weight: 2 parts of jasmine, 2 parts of wild chrysanthemum, 1 part of lily, 1 part of gardenia, 2 parts of rose, 1 part of osmanthus, 2 parts of honeysuckle, 2 parts of mint, 1 part of sweet orange Peel, 1 part grapefruit peel, 1 part lavender, 1 part wintergreen, 2 parts pine needles, 5 parts aloe vera, 4 parts sophora flavescens, 3 parts licorice, 3 parts green tea leaves, 3 parts ginkgo biloba, 2 parts hot pepper and 2 parts peppercorns. Crush each group into powder with a pulverizer and mix, slowly add 60% ethanol, the ratio of liquid to material is 1:25, put it in a sealed container with a temperature of 20°C-35°C for 30 hours; filter the solution several times to remove the dregs; the ethanol in the solution was recovered by distillation under reduced pressure to obtain the basic plant extract X.

[0025] 2. Get 15 parts by weight of basic plant extract X, 6 parts of surfactant (sodium cocoyl methyl taurate), 2 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com