A kind of highly transparent PET anti-scratch masterbatch and preparation method

A masterbatch, transparent technology, applied in the field of high transparent PET scratch-resistant masterbatch and its preparation, can solve the problem that the hardness and wear resistance vary greatly, the hardness and scratch resistance of the sheet are not changed obviously, and the sheet cannot be reached. Anti-scratch strength and other issues, to improve the surface hardness and thermal deformation temperature, improve the anti-scratch performance, improve the effect of anti-scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

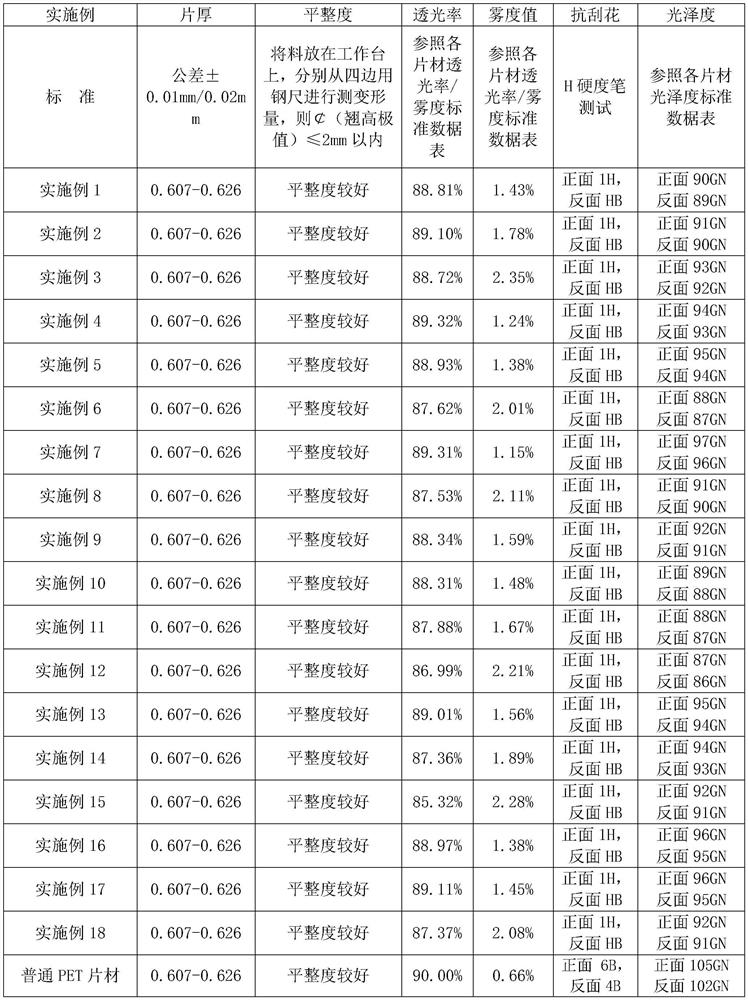

Examples

preparation example Construction

[0070] A preparation method of highly transparent PET anti-scratch masterbatch, comprising the following steps:

[0071] S1 firstly prepare the raw materials according to the proportion of each component, the PET raw material is ground into powder in advance, the particle size is less than 60 mesh; S2 mix each raw material evenly for later use, the feeding order is to add 1 / 3-2 / 3 of the total amount of PET first, Then add other raw materials, add the remaining PET, and finally add PCTA;

[0072] In S3, put the uniformly mixed raw materials in S2 into the extruder and extrude them.

[0073] The extruder in S3 is divided into 12 temperature setting zones, the temperature of zone 1 is 190-210℃, the temperature of zone 1, zone 2, zone 3 and zone 4 increases gradually, zone 4, zone 5, zone 6 and zone 7 , Zone 8, and Zone 9 maintain a constant temperature, and after Zone 10, the temperature begins to drop, and the temperature in Zone 12 is higher than that in Zone 1.

Embodiment 19

[0079] A preparation method of highly transparent PET anti-scratch masterbatch,

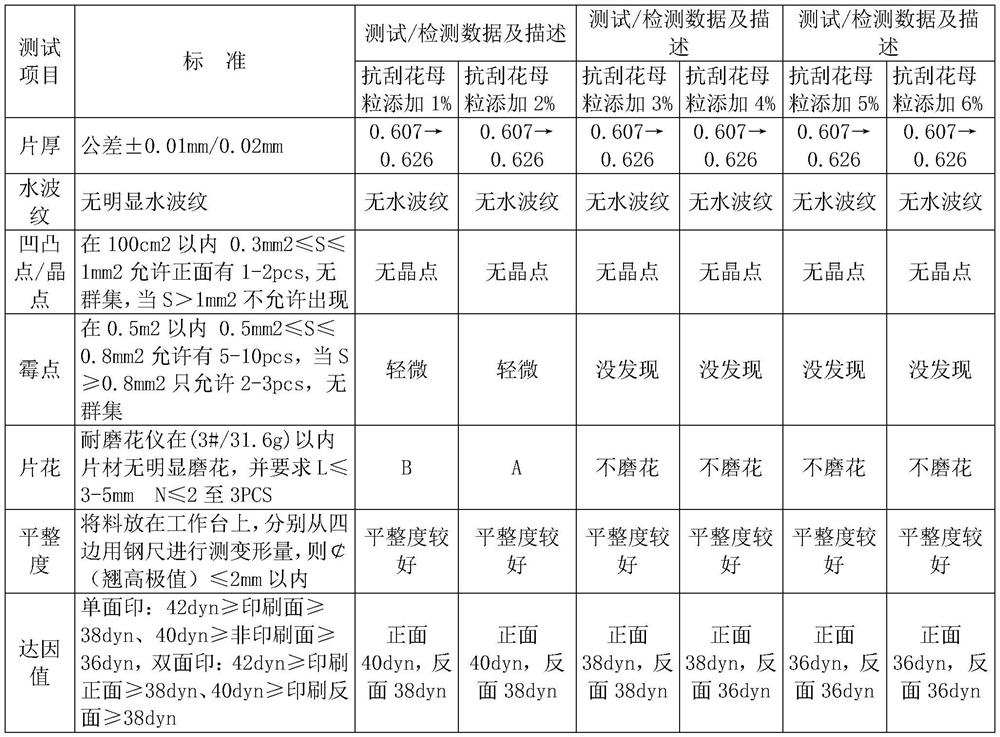

[0080] Adding the masterbatch obtained in the foregoing embodiments to PET comprises the following steps respectively:

[0081] S1 firstly prepare the raw materials according to the proportion of each component, the PET raw material is ground into powder in advance, the particle size is 60 mesh-70 mesh; S2 mixes all raw materials evenly for later use, and the order of feeding is to add 1 / 1 of the total amount of PET powder in S1 first 2. Then add nano-spherical silica, micron-sized spherical silica, polyester wax, calcium montanate, antioxidant, the remaining PET powder, and finally add PCTA; set the temperature of the high-speed mixer at 90-120 ℃, preheat to a certain extent, stir at low speed within 5-10 minutes at the beginning, the rotation speed is 200-240 rpm, and then stir at high speed for 8-13 minutes, the rotation speed is 700-800 rpm;

[0082] S3 puts the raw materials evenly stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com