Composite dust suppressant and preparation method thereof

A dust suppressant and composite technology, which is applied in the field of composite dust suppressant and its preparation, can solve the problems of dust suppressant surface tension and low dust suppression efficiency, and achieve high dust suppression efficiency, high dust suppression efficiency, and low dust suppression efficiency. The effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

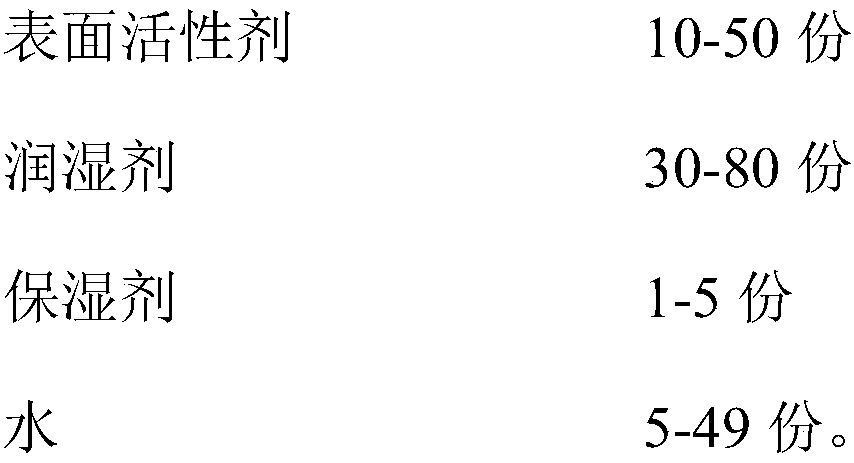

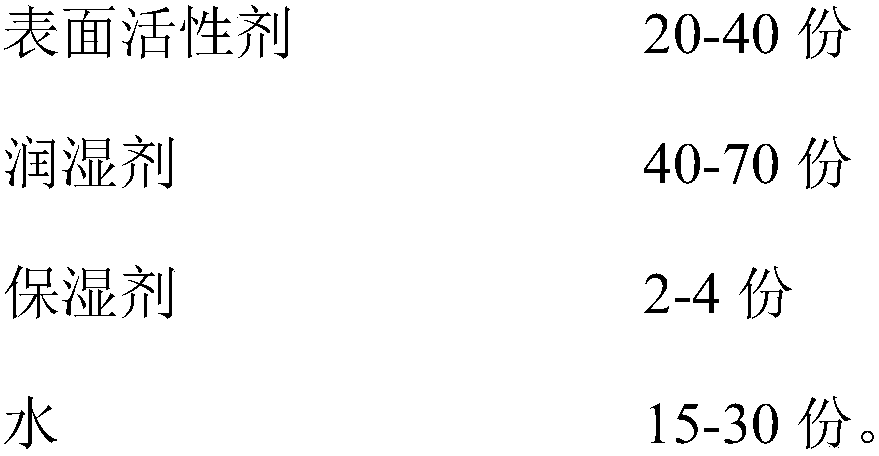

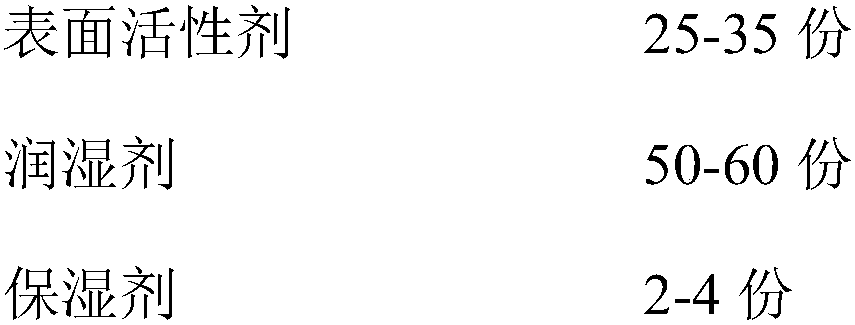

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a composite dust suppressant and its preparation method. The composite dust suppressant is composed of 30g of surfactant, 55g of natural phenol polyoxyethylene ether, 3g of starch and 22g of deionized water, wherein the surfactant is composed of sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether. Oxyethylene ether composition, the mass ratio of sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether is 1:3;

[0036] The preparation method of above-mentioned composite dust suppressant comprises the steps:

[0037] Dissolve the surfactant and natural phenol polyoxyethylene ether in water and disperse for 2.5 hours to obtain a mixture;

[0038] Add starch to the mixture and stir at 1000r / min to obtain a composite dust suppressant.

Embodiment 2

[0040] This embodiment provides a composite dust suppressant and its preparation method. The composite dust suppressant is composed of 25g of surfactant, 60g of C16 isomeric alcohol, 2g of polyvinyl alcohol and 25g of deionized water, wherein the surfactant is composed of sodium cetyl sulfonate and lauryl polyoxygen Vinyl ether composition, the mass ratio of sodium cetyl sulfonate and polyoxyethylene lauryl ether is 1:2;

[0041] The preparation method of above-mentioned composite dust suppressant comprises the steps:

[0042] Dissolving surfactant and C16 isomeric alcohol in water and dispersing for 3 hours to obtain a mixture;

[0043] Add polyvinyl alcohol to the mixture and stir at 800r / min to obtain a composite dust suppressant.

Embodiment 3

[0045] This embodiment provides a composite dust suppressant and its preparation method. The composite dust suppressant is made up of 35g of surfactant, 50g of fatty alcohol polyoxyethylene ether, 4g of amino acid and 20g of deionized water, wherein the surfactant is composed of sodium di-octyl maleate sulfonate and lauryl polyoxyethylene ether, the mass ratio of the maleic acid di-sec-octyl sodium sulfonate and non-lauric alcohol polyoxyethylene ether is 1:4;

[0046] The preparation method of above-mentioned composite dust suppressant comprises the steps:

[0047] Dissolving the surfactant and fatty alcohol polyoxyethylene ether in water, and dispersing for 4 hours to obtain a mixture;

[0048] Add amino acid to the mixture and stir at 1200r / min to obtain a composite dust suppressant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com