A kind of waste emulsion sludge treatment method

A waste emulsion and treatment method technology, which is applied in waste fuel, petroleum industry, fuel, etc., can solve the problems of waste emulsion sludge, complicated treatment process, secondary pollution, etc., achieve fast treatment efficiency and ensure combustion effect , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

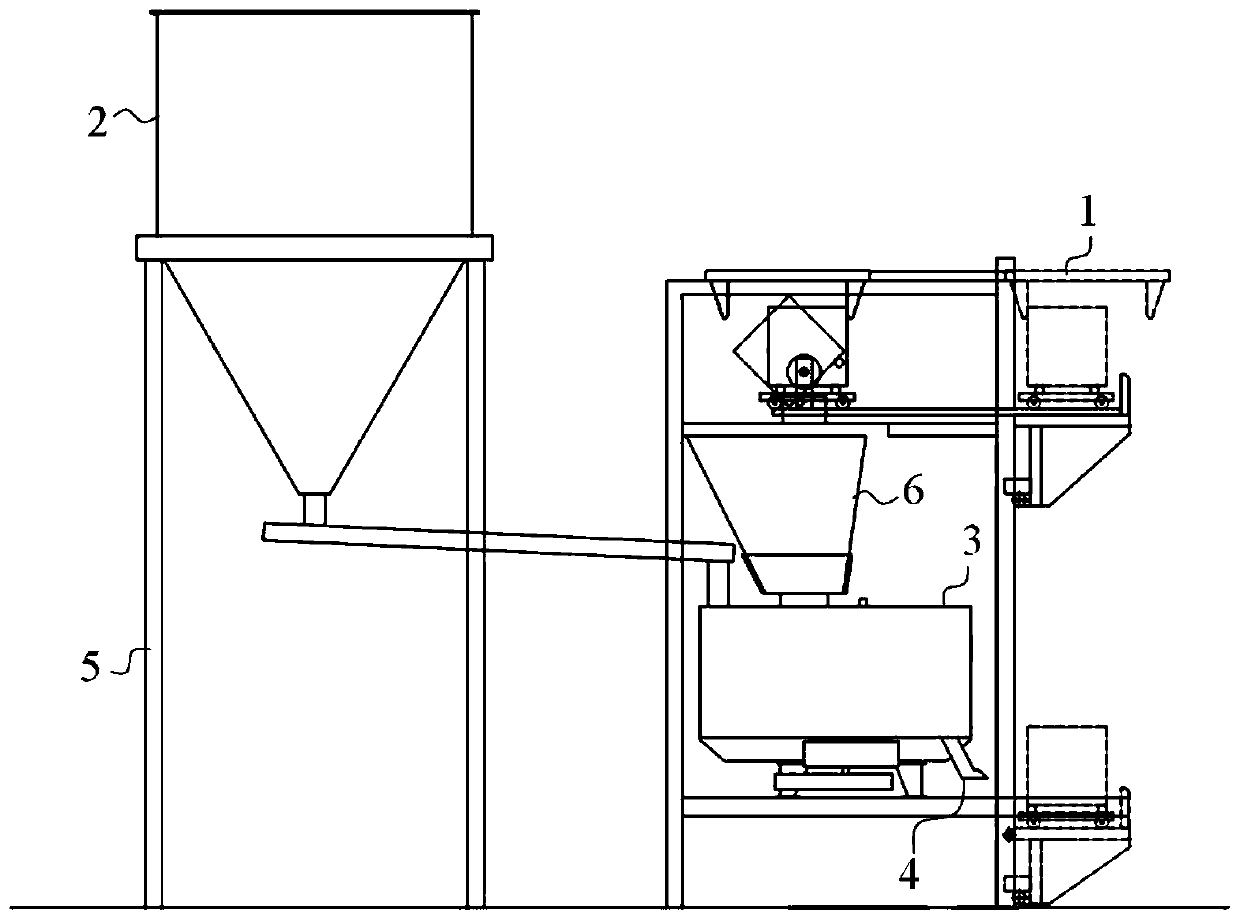

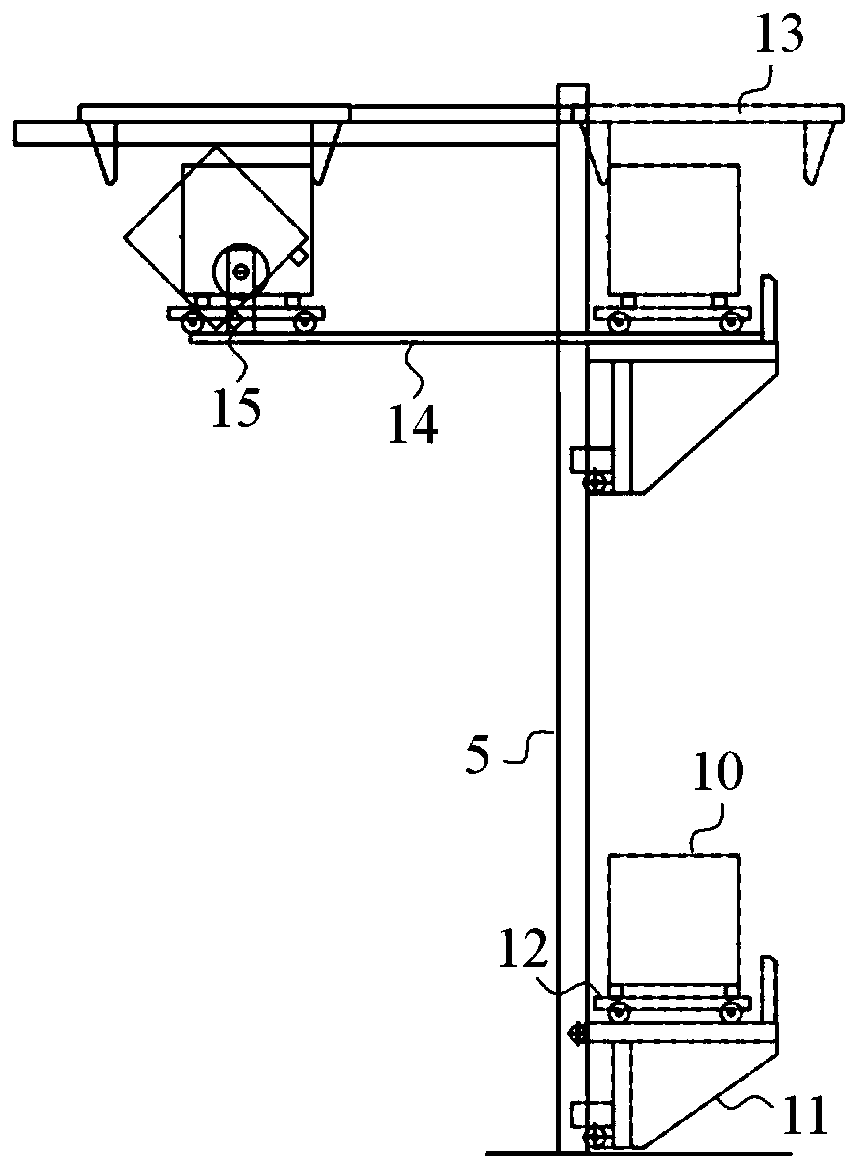

[0045] The method for treating waste emulsion sludge in this embodiment includes the following steps:

[0046] 1. Ingredients, quantitatively proportion the waste emulsion sludge and fly ash and proceed to the next step;

[0047] 2. Mixing, mixing the materials prepared in the batching step, and making them into powdered granules through repeated rolling, stirring and mixing operations;

[0048] 3. Discharge and output the final product of the mixing step.

[0049] Existing waste emulsion treatment usually adopts chemical treatment methods. After demulsification, flocculation, air flotation, water treatment and other processes, the waste emulsion is finally treated and discharged. This treatment method first requires special equipment. A series of chemical reactions are carried out in the equipment. It is difficult for the treated products and accompanying organisms to meet the emission standards, which increases the burden on the environment. After testing and analysis, the calorific...

Embodiment 2

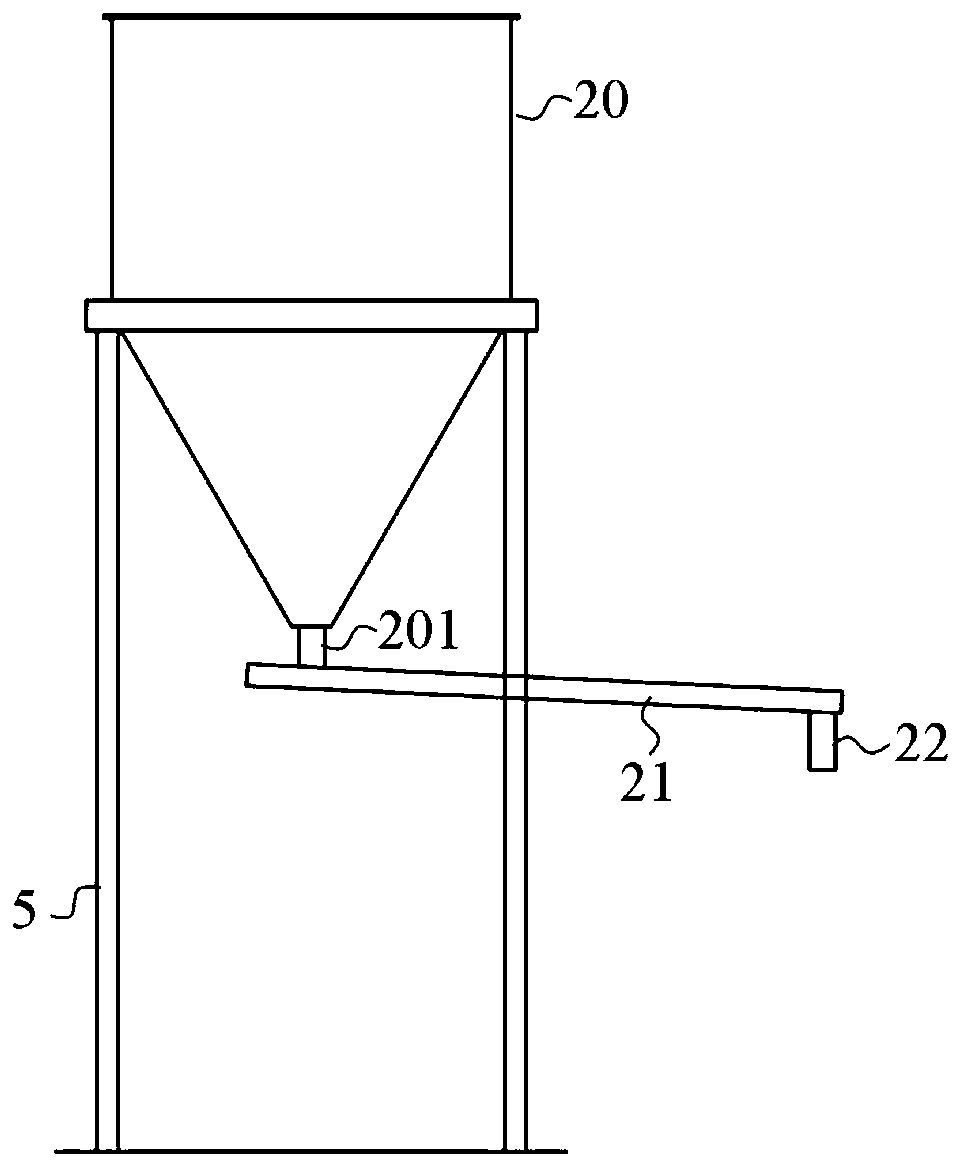

[0090] The waste emulsion sludge treatment method of this embodiment is further improved on the basis of Example 1. Before the batching step, the material selection step is carried out. The water content of the mixed fly ash is ≤ 1%, and the waste The water content of the emulsion sludge is ≤50%.

[0091] The product obtained by this method must be combustible and its combustion effect must be guaranteed. The water content of the final product must be very low. Therefore, the raw materials (waste emulsion sludge) and additives (fly ash) need to be selected when compounding. Select materials that meet the above water content standards for batching. When the water content of fly ash is greater than 1%, the product obtained by mixing is easy to agglomerate, which is not conducive to combustion and cannot well neutralize and absorb the water in the waste emulsion sludge. , The water content of the waste emulsion sludge is greater than 50%. In order to absorb the water during the mixi...

Embodiment 3

[0093] The waste emulsion sludge treatment method of this embodiment is further improved on the basis of embodiment 2. Before the batching step, the material selection step is carried out. The content of particles with a particle size of ≤ 1 mm in the blended fly ash is ≥ 90%.

[0094] In actual operation, it is found that the particle size of fly ash affects the mixing effect of the materials during the mixing process, thereby affecting the combustion effect of the mixed product. When the content of particles with a particle size ≥ 1mm in the fly ash is greater than 10% , There are more solid slag and agglomerated materials in the mixed product. This material cannot be burned sufficiently during combustion, and it will affect the forward flow of the fuel conveying equipment during combustion. Therefore, before the batching, the pulverized coal The ash is selected first, so that the content of particles with a particle size of ≤1mm in the mixed fly ash is ≥90% to ensure the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com