Method for forming graphene film, mems microphone and method for forming same

A graphene film and microphone technology, applied in coatings, sensors, gaseous chemical plating, etc., can solve problems such as breakage and cracking of graphene films, achieve cost savings, good sensitivity and mechanical strength, and reduce cracking or damage. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Graphene has great application prospects due to its excellent properties in mechanics, electricity, optics and chemistry. However, when it is necessary to form a graphene film on a specific substrate, it is usually necessary to provide a transitional substrate, and form the graphene film on the transitional substrate, and then transfer the formed graphene film to the specific substrate. In this way, not only the transfer process of the graphene film is cumbersome, but also easy to cause cracking or damage of the graphene film.

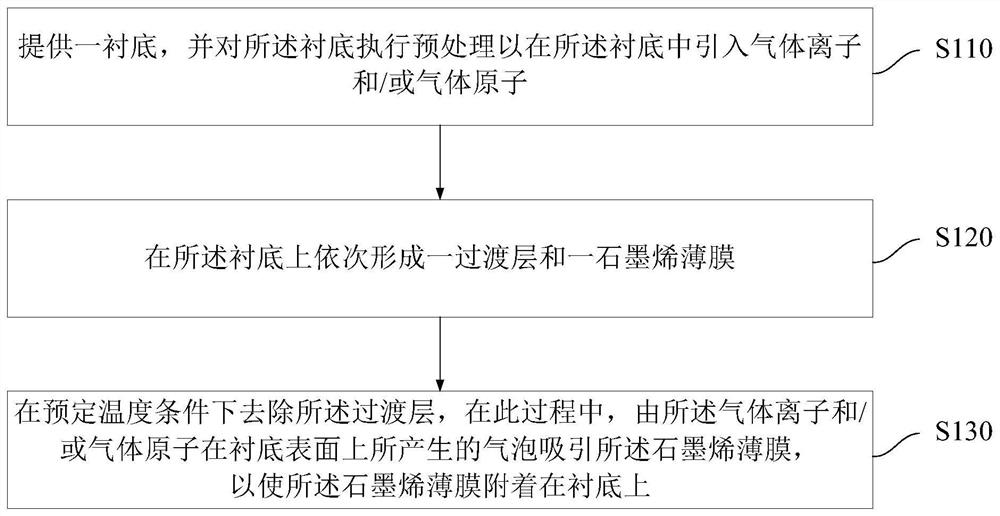

[0037] To this end, the invention provides a method for forming a graphene film. figure 1 It is a schematic flow diagram of a method for forming a graphene layer in Embodiment 1 of the present invention, as figure 1 Shown, the formation method of described graphene layer comprises:

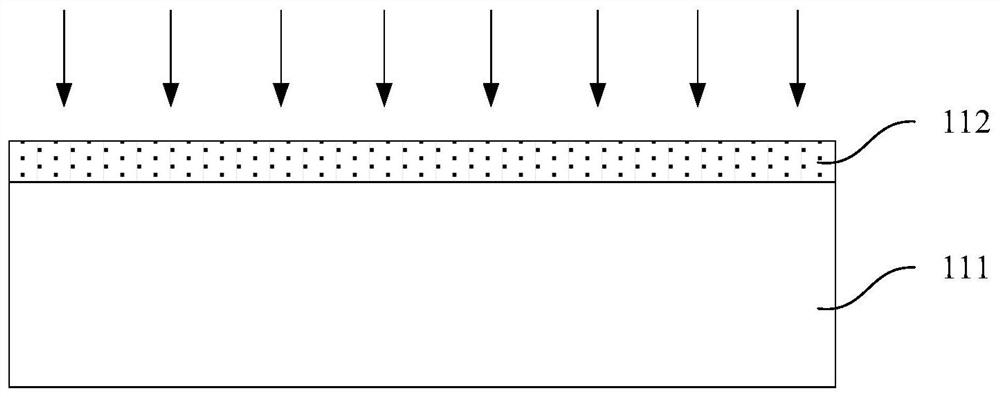

[0038] Step S110, providing a substrate, and performing pretreatment on the substrate to introduce gas ions and / or gas atoms into the substrate;

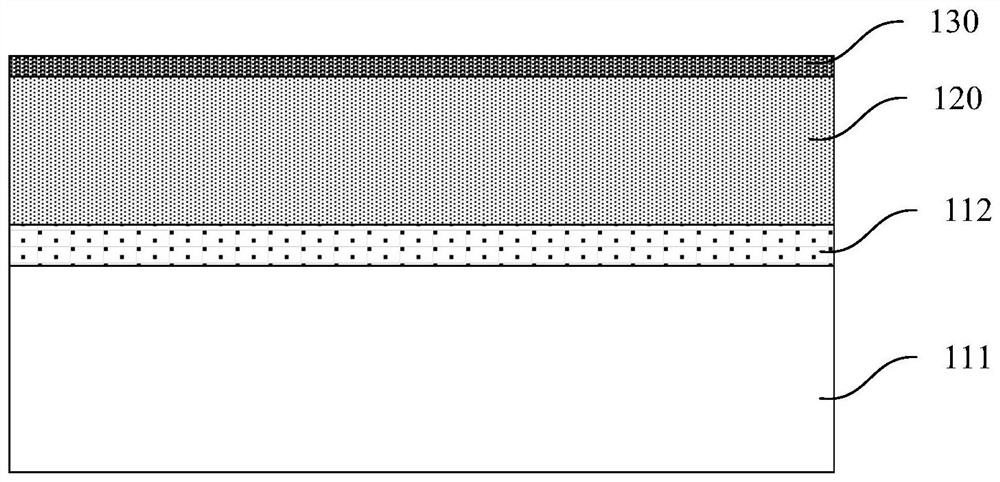

[0039] Step S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com