Composite positive electrode material, positive electrode sheet and all-solid lithium battery

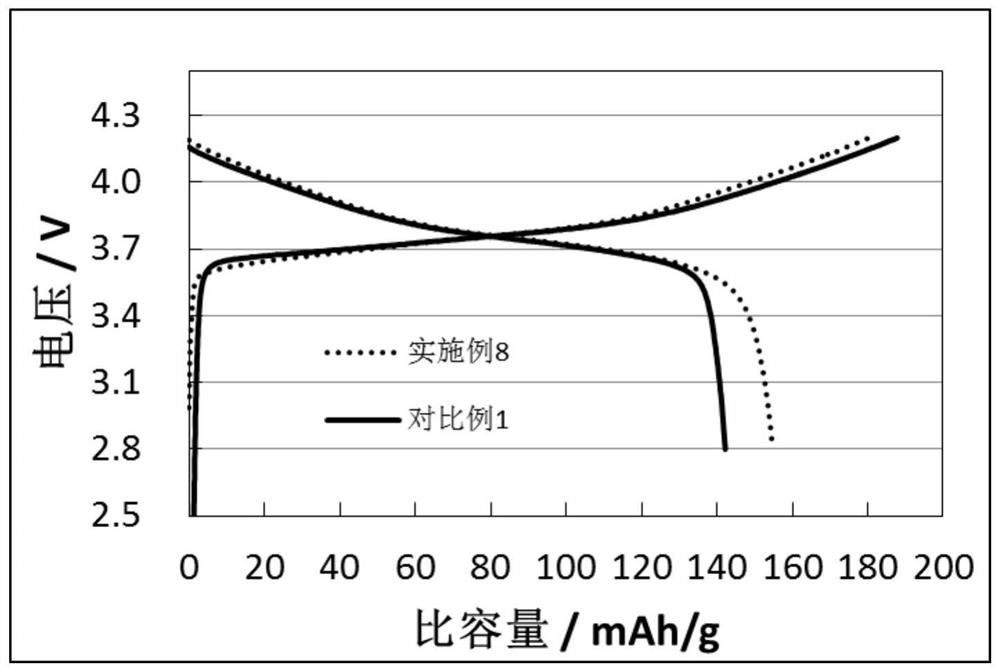

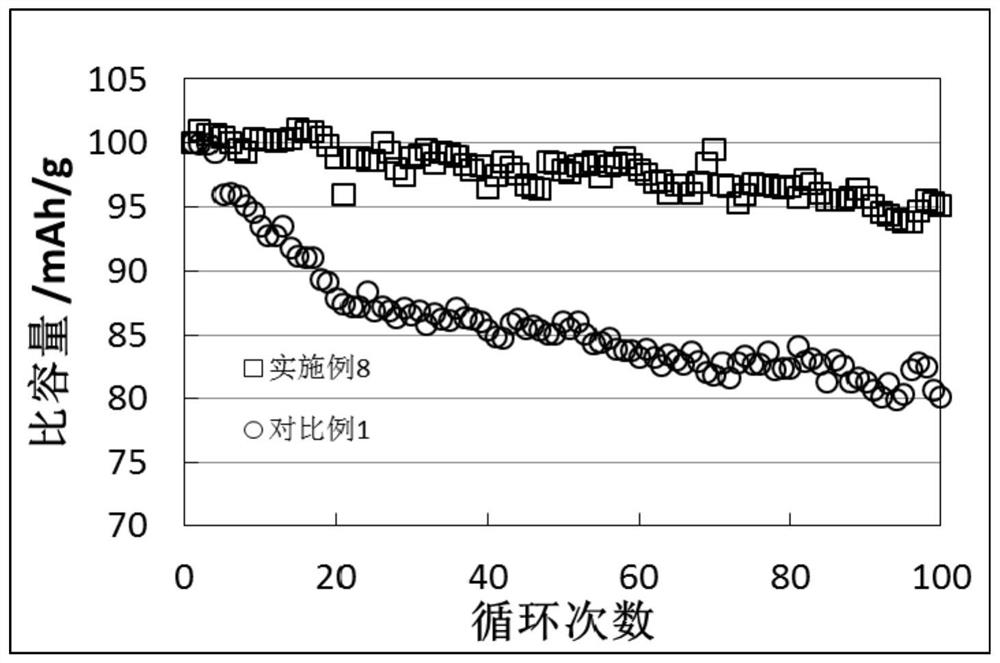

A composite positive electrode material and lithium battery technology, which is applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problem of small effective contact area between solid electrolyte and electrode materials, poor rate performance and cycle performance, and low discharge specific capacity, etc. problem, to achieve the effect of improving rate performance and cycle stability, improving utilization rate, and reducing lithium impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

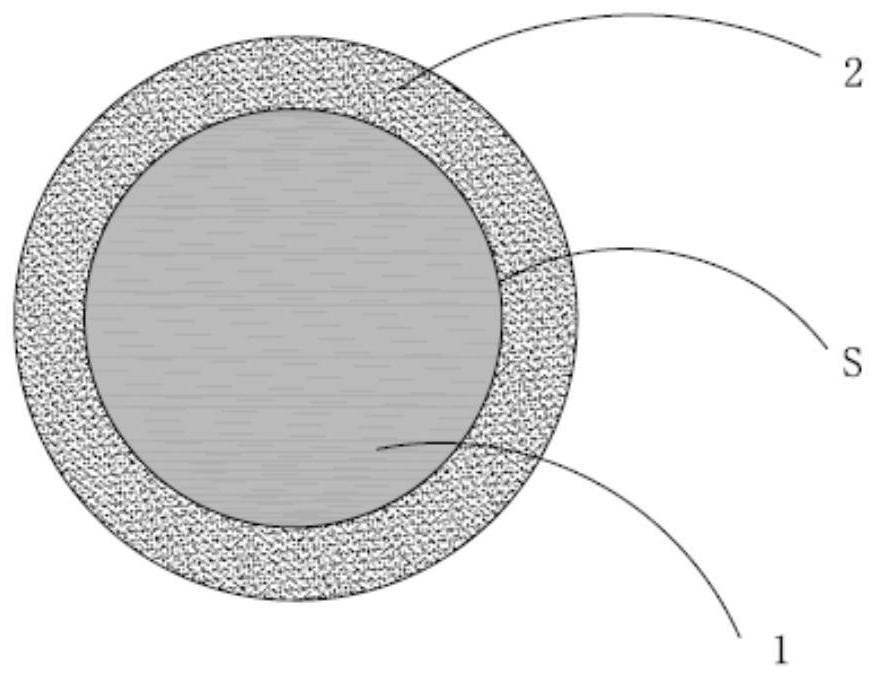

[0024] According to the preparation method of the composite positive electrode material of the second aspect of the present application, it is used to prepare the composite positive electrode material of the first aspect of the present application, comprising the steps of: making the positive electrode material Li n Ni x co y m z N m o 2Disperse into the ball milling medium and use a planetary ball mill for ball milling to break the positive electrode material into primary particles, and then anneal in an oxygen atmosphere to obtain the core material; dissolve soluble lithium salts, cobalt salts, and compounds containing Ma A large amount of complexing agent is continuously stirred to form a uniform mixed solution, and the pH value and temperature are adjusted to form a uniform sol; the obtained core material is added to the sol, continuously stirred until uniform, dried, and the shell material is coated On the surface of the core material, heat treatment is then performed...

Embodiment 1

[0042] Spherical cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 Add it into a planetary ball mill for ball milling to break it into primary particles, the ball milling speed is 400rpm, the ball milling time is 8h, the ball-to-material ratio is 3:1, the ball milling medium is ethanol, and it is dried after ball milling, and then placed in an oxygen atmosphere at 850°C Anneal for 10 hours to obtain the core material; accurately weigh lithium acetate, cobalt acetate and aluminum isopropoxide according to the molar ratio Li:Co:Al=1:0.97:0.03, dissolve them in ethanol, and add a certain amount of citric acid as a complexing agent Adjust the pH value of the agent and continue to stir to form a uniform mixed solution, and continue to stir at 80°C to make the shell material form a uniform sol.

[0043] The core material is added to the sol, placed in a water bath at 80°C and continuously stirred to form a gel, then vacuum-dried, and then heat-treated. The heat treatment process is 900...

Embodiment 2

[0046] The preparation method of the composite positive electrode material is the same as in Example 1, the difference is that the LiNi 0.5 co 0.2 mn 0.3 o 2 replace with Li 0.95 Ni 0.5 co 0.2 mn 0.3 o 2 According to the method of Example 1, an all-solid-state lithium battery was constructed to evaluate the electrochemical performance of the composite cathode material. The all-solid-state lithium battery was disassembled, and the cycled composite positive electrode material was tested, and the concentration of element Ma on the surface of the shell was greater than the concentration of element Ma at the interface between the shell and the core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com