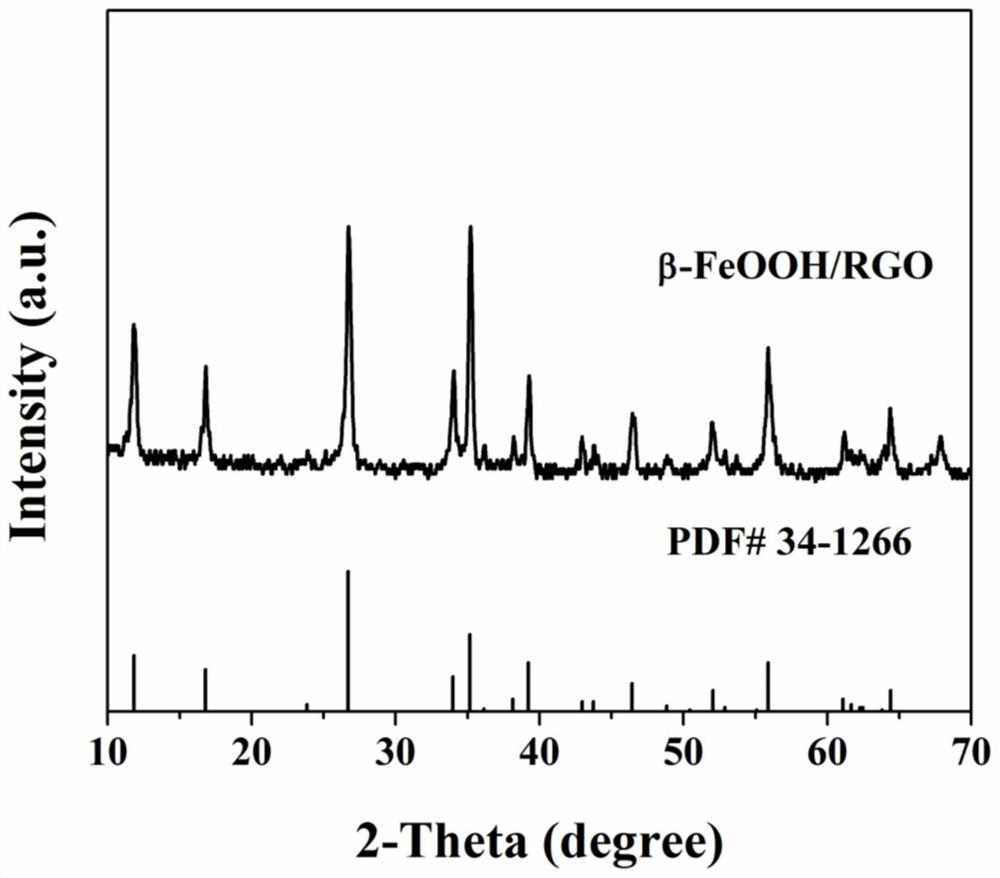

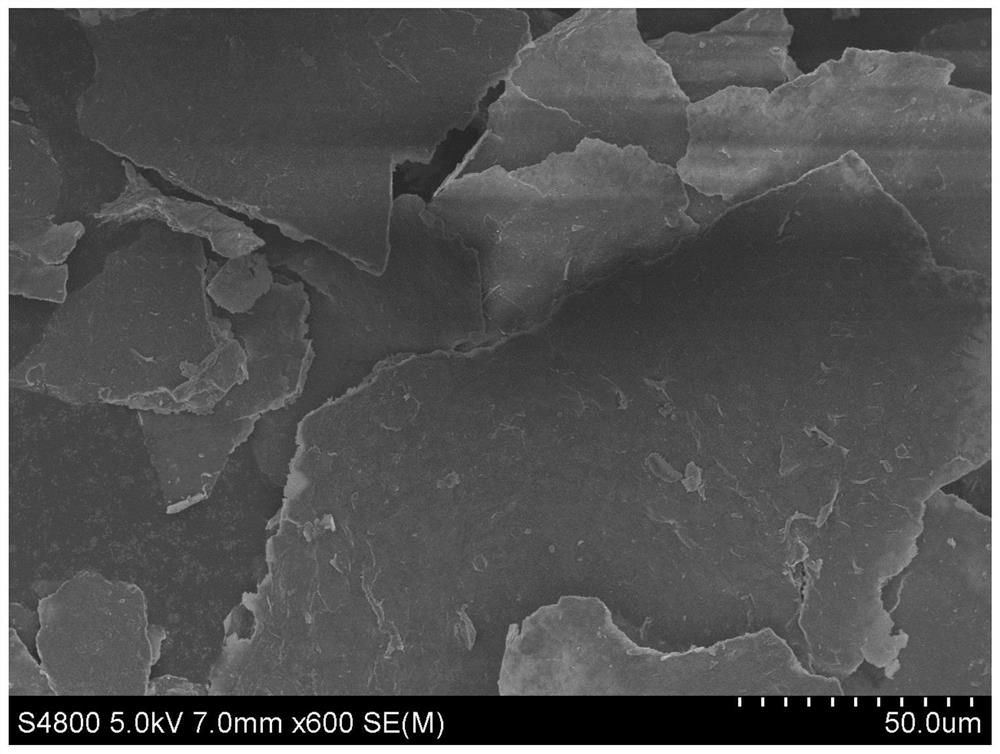

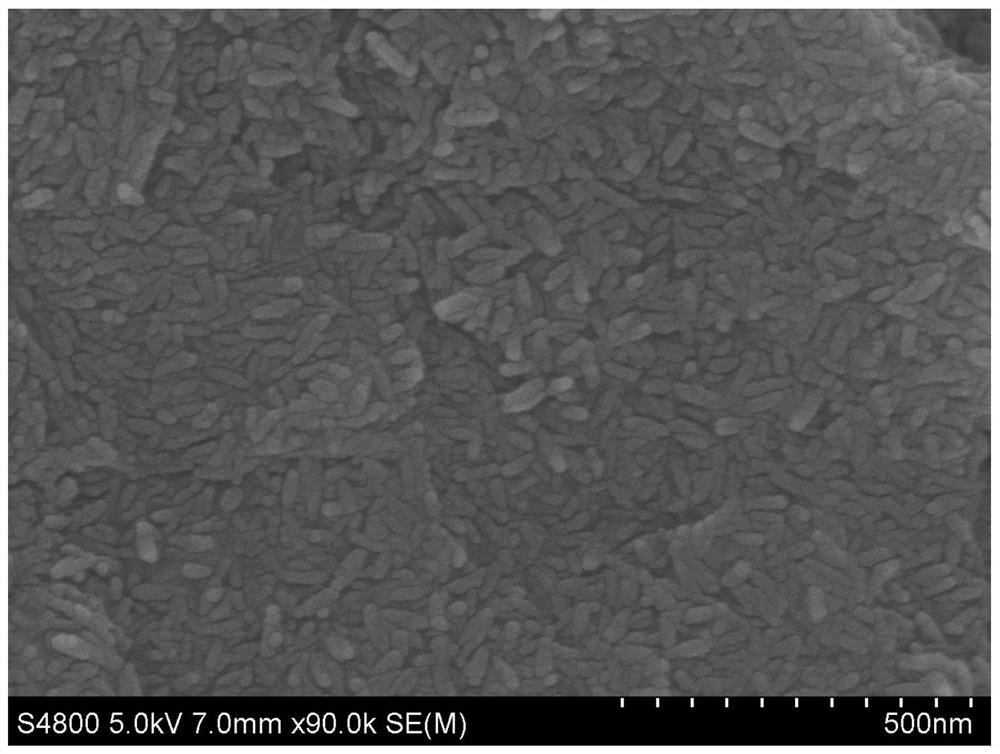

A preparation method of ultra-large lamellar rgo loaded ultrafine β-feooh nanoparticles lithium-ion battery anode material

A lithium-ion battery and nanoparticle technology, applied in the field of electrochemistry, can solve the problems of the specific capacity to be further improved and the poor conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Dispersion of the commercially available oxide oxide in 25 ml of deionized water, then dispersed 1H with 300 W ultrasonic generator, forming a dispersion uniform oxide-suspension A;

[0031] 2) The analytical pure soluble iron-containing hexahydrofluchloride, sodium chloride and 0.3 g of urea were added to 25 ml of anhydrous ethanol and 10 ml of deionized water, and the salt was dissolved, then the salt was dissolved, then added to the suspension A, The mixed solution of salt and oxide oxide is configured, wherein the concentration of the iron salt is 0.05 mol / L, the sodium salt concentration is 2 / 3 of the iron salt concentration, and then the mixed solution is dispersed with an ultrasonic generator to dispense the suspension B;

[0032] 3) Pour the suspension B prepared in the above-mentioned hydrothermal reaction kettle polytetrafluoroethylene liner, the filling degree is 30%, then seal the reactor, then put it in a homogeneous hydrothermal reactor 50 ° C for water p...

Embodiment 2

[0039] 1) Disperse commercially available graphene in 30 ml of deionized water, then dispersed 3H with 300 W ultrasonic generator to form a dispersion uniform oxide inkylene suspension A;

[0040] 2) Pure soluble iron salt seven hydrazine sulfate, sodium chloride and 0.35 g of urea were added to 25 ml of anhydrous ethanol and 12 ml of deionized water, thoroughly stirred to dissolve the salt, then added to suspension A, configure The mixed solution of salt and oxide oxide, wherein the concentration of the iron salt is 0.2 mol / L, the sodium salt concentration is 2 / 3 of the iron salt concentration, and then the mixed solution is dispersed with an ultrasonic generator to dispense the suspension B;

[0041] 3) Pour the suspension B prepared in the above-mentioned hydrothermal reaction kettle polytetrafluoroethylene liner, the filling degree is 80%, then seal the reaction kettle, and then put it in a homogeneous hydrothermal reactor The water heat reaction is carried out at 70 ° C for...

Embodiment 3

[0045] 1) Dispersion of commercially available oxide in graphene in 35 ml of deionized water, then dispersed by 300 W ultrasonic generator to form a dispersion uniform oxide inkylene suspension A;

[0046] 2) Pure soluble iron salt nine hydrogen nitrate iron, sodium chloride and 0.4 g of urea were added to 25 ml of anhydrous ethanol and 14 ml of deionized water, and thoroughly stirred the salt to dissolve, then added to suspension A, configured The mixed solution of salt and graphene, wherein the concentration of the iron salt is 0.3 mol / L, the sodium salt concentration is 2 / 3 of the iron salt concentration, and then the mixed solution is dispersed with an ultrasonic generator to disperses suspension B;

[0047] 3) Pour the suspension B prepared to pour the phase water-heat reactor, the filling degree of 60%, then seal the reaction kettle, then placed in a homogeneous hydrothermal reactor Gas-hot reaction is carried out at 150 ° C for 3 h, and after the end of the reaction, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com