Charged biomimetic implantation film material regulated and controlled through magneto-electric coupling and preparation method thereof

A technology of magnetoelectric coupling and membrane materials, which can be applied in tissue regeneration, medical formula, medical science, etc., can solve the problems of unstable long-term repair effect and potential attenuation, and achieve good bone defect repair effect, good flexibility and product effect stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

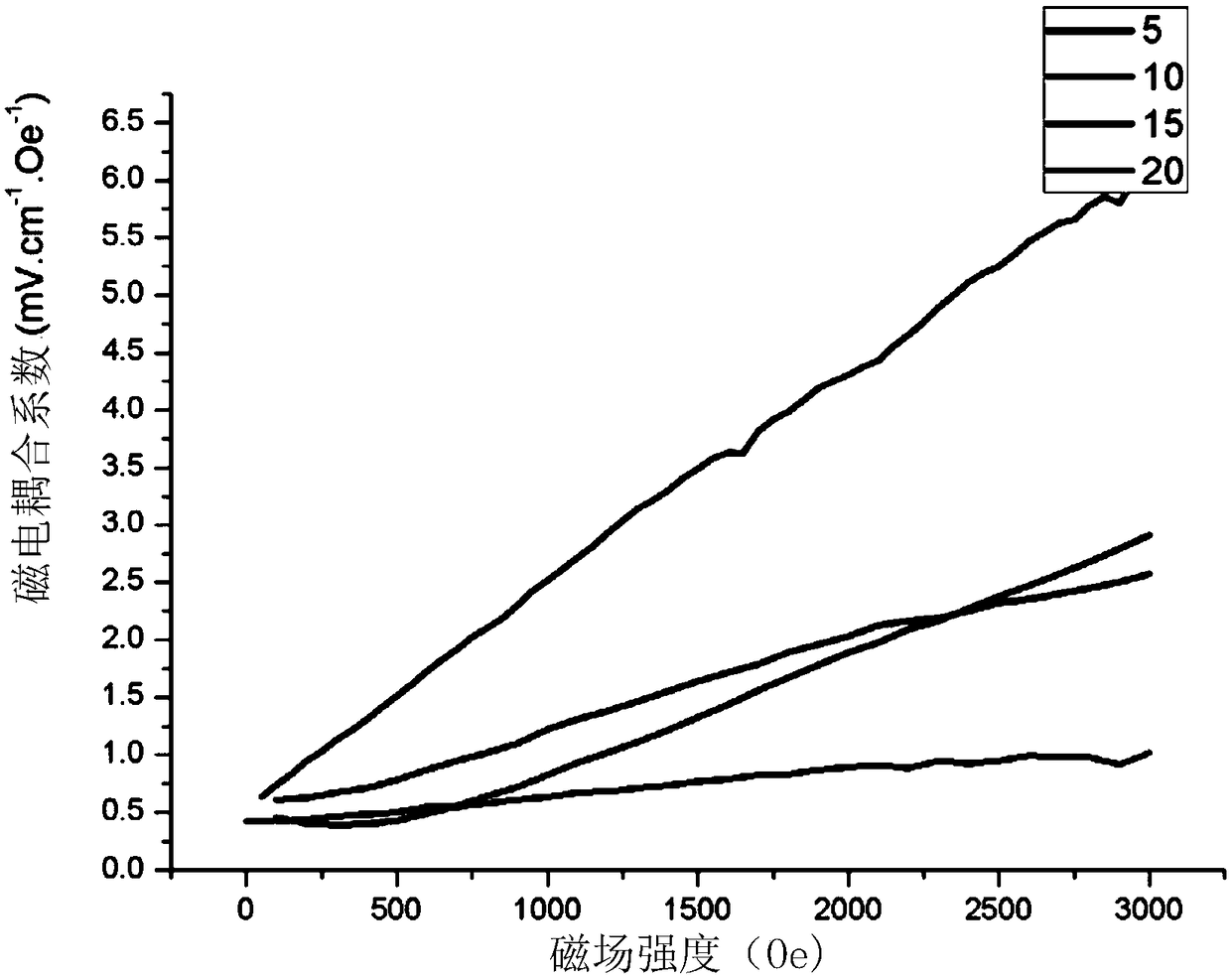

[0026] (1) Weigh 0.11g of cobalt ferrite nanoparticles, add them to 20ml of azatrimethylformamide, and vibrate ultrasonically for 3 hours to obtain a uniformly dispersed magnetic nanoparticle dispersion;

[0027] (2) Weigh 2g of polymer P (VDF-TrFE) and add it to the magnetic nanoparticle dispersion obtained in step (1) to make the concentration of the polymer solution 0.1g / ml, and make the cobalt ferrite magnetic particles in the polymer The mass percentage in the matrix is 5%, ultrasonic and stirring for 3 hours, so that the magnetic particles are uniformly dispersed in the polymer matrix, and a mixture of magnetic particles and ferroelectric polymer matrix is obtained;

[0028] (3) Cast the mixed solution obtained in step (2) in a casting machine, and dry the film obtained by casting at a temperature of 40° C. to obtain a composite film material with a film thickness of 70 μm;

[0029] (4) The composite membrane material obtained in step (3) is annealed, the annealing temperat...

Embodiment 2

[0032] (1) Weigh 0.22 g of cobalt ferrite nanoparticles, add them to 20 ml of organic solvent nitrosidine dimethylformamide, and vibrate ultrasonically for 3 hours to obtain a uniformly dispersed magnetic nanoparticle dispersion;

[0033] (2) Weigh 2g of polymer P (VDF-TrFE) and add it to the magnetic nanoparticle dispersion obtained in step (1) to make the concentration of the polymer solution 0.1g / ml, and make the cobalt ferrite magnetic particles in the polymer The mass percentage in the matrix is 25%, ultrasonic and stirring for 3 hours, so that the magnetic particles are uniformly dispersed in the polymer matrix, and a mixture of magnetic particles and ferroelectric polymer matrix is obtained;

[0034] (3) Cast the mixed solution obtained in step (2) in a casting machine, and dry the film obtained by casting at a temperature of 100°C to obtain a composite film material with a film thickness of 70 μm;

[0035] (4) The film material obtained in step (3) is annealed, and the an...

Embodiment 3

[0038] (1) Weigh 0.17 g of cobalt ferrite nanoparticles, add them to 20 ml of organic solvent nitrosidine dimethyl formamide, and vibrate ultrasonically for 3 hours to obtain a uniformly dispersed magnetic nanoparticle dispersion;

[0039] (2) Weigh 2g of polymer P (VDF-TrFE) and add it to the magnetic nanoparticle dispersion obtained in step (1) to make the concentration of the polymer solution 0.1g / ml, and make the cobalt ferrite magnetic particles in the polymer The mass percentage in the matrix is 15%, ultrasonic and stirring for 3 hours, so that the magnetic particles are uniformly dispersed in the polymer matrix, and a mixture of magnetic particles and ferroelectric polymer matrix is obtained;

[0040] (3) Cast the mixed solution obtained in step (2) in a casting machine, and dry the film obtained by casting at a temperature of 70°C to obtain a composite film material with a film thickness of 70 μm;

[0041] (4) The film material obtained in step (3) is annealed, and the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com