Preparation method of flexible micron/nano pressure sensor on the basis of printing mode

A pressure sensor and sensor technology, applied in the field of sensors, can solve problems such as patent publications that have not yet been found, and achieve the effects of favorable environmental protection, pollution reduction, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a flexible micro-nano pressure sensor based on a printing method, the steps are as follows:

[0042] (1) Weigh 0.5g, 1g, 1.5g, 2g, 3g, 4g polyacrylonitrile solid powder with an electronic balance, put them into six 100mL beakers respectively for later use, and paste labels to show the difference; Add 50ml of DMF solution into the polyacrylonitrile beaker respectively, and place the solution in a water bath for heating in a water bath. Take 15ml of the light yellow solution with a measuring cylinder and pour it into a glass plate of 12×12cm, and place the glass plate in a fume hood for heat treatment; the solvent in the PAN solution is volatilized by heating on a heating plate, and finally different thicknesses of Transparent film. In order to ensure a gentle volatilization rate, set the heating temperature to 45°C.

[0043] (2) Adhere the obtained transparent film to a 2.5×8cm glass slide through polyimide double-sided tape; in a dark environmen...

Embodiment 2

[0048] A method for preparing a flexible micro-nano pressure sensor based on a printing method, the method constructs a micro-nano layer and a conductive layer:

[0049] The micro-nano layer exposes and develops the designed micro-nano-patterned film sheet and polyacrylonitrile film to obtain a cured photosensitive adhesive with a micro-nano structure, while the unprotected area uses N,N-dimethylformaldehyde that can dissolve the film Carry out semi-melt-through etching with methyl formamide, and then perform ultrasonic treatment on it to remove the cured photosensitive adhesive to obtain a film with a concave-convex structure; the conductive layer uses a liquid phase method to attach multi-walled carbon nanotubes to the film by pulling. , and the devices were assembled in pairs, and a flexible micro-nano pressure sensor based on printing was obtained.

[0050] Preferably, the steps are as follows:

[0051] (1) Production of transparent PAN film;

[0052] (2) Realization of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

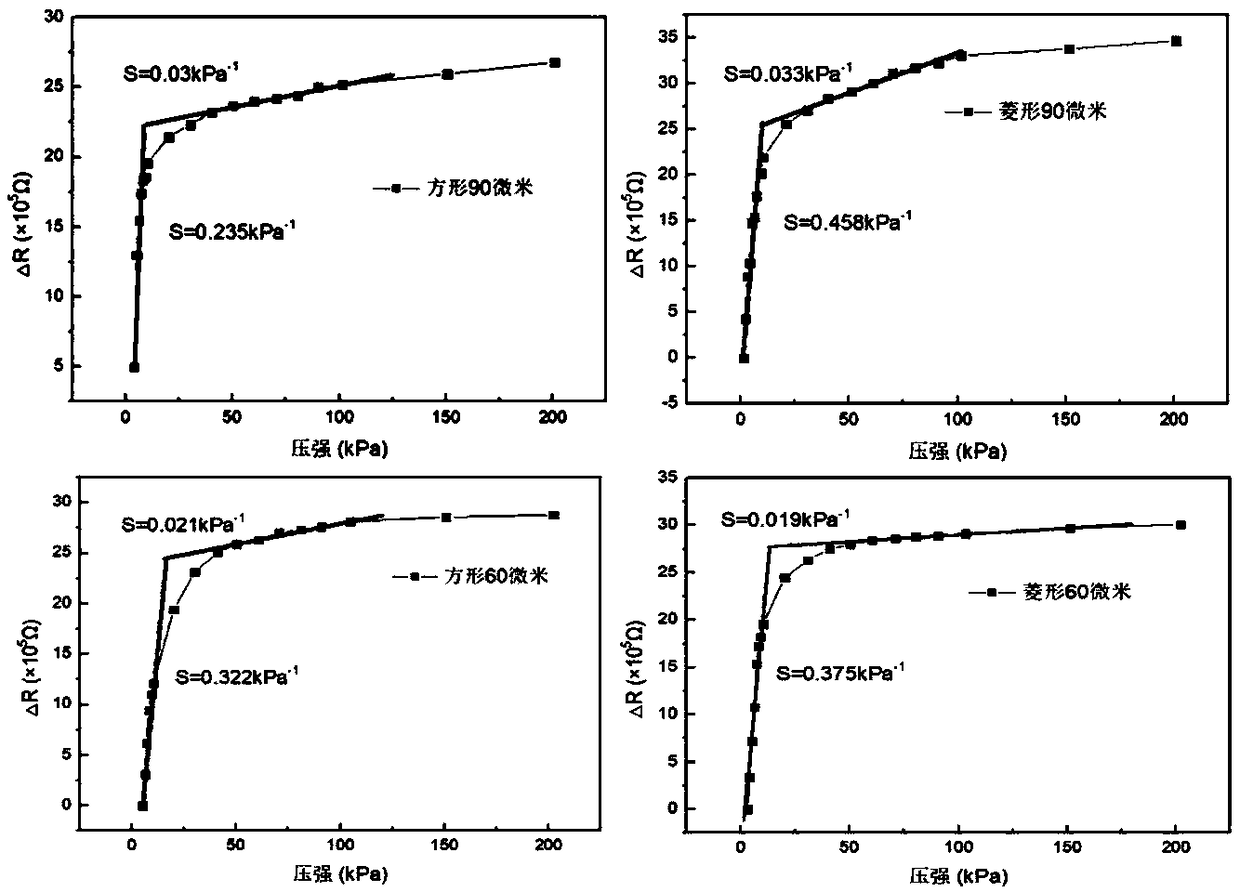

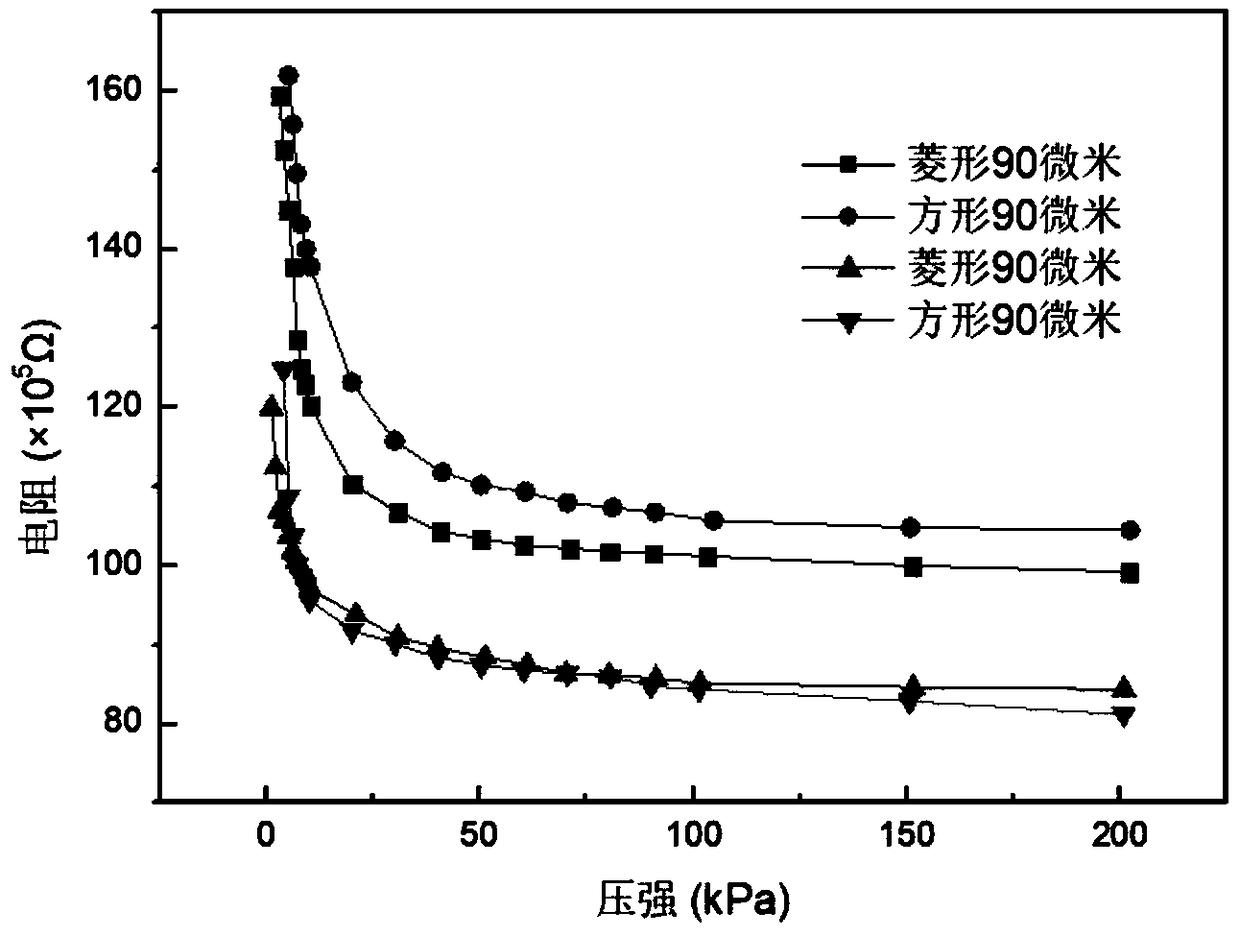

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com