Preparation method of ZnSnO3@rGO composite material

A composite material, H2SO4 technology, applied in the field of preparation of ZnSnO3@rGO composite materials, can solve the problems of unfavorable electromagnetic waves and limit the application of graphene, and achieve the effect of excellent wave absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

[0035] Preparation of composite materials

[0036] Graphene oxide was prepared by adding concentrated H 2 SO 4 / H 3 PO 4 (360:40mL) solution, giving off a slight heat. The reaction mixture was then heated to 50°C and stirred magnetically for 12 hours. When the reaction cooled to room temperature, it was poured into 30% HO 2 o 2 (3 mL) of ice, the color of the mixture changed to yellow. Graphene oxide was obtained after filtration, washed with hydrochloric acid (concentrated hydrochloric acid and water volume ratio 1:10) to remove metal ions, and then vacuum freeze-dried for 24 hours. The rest of the chemical reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

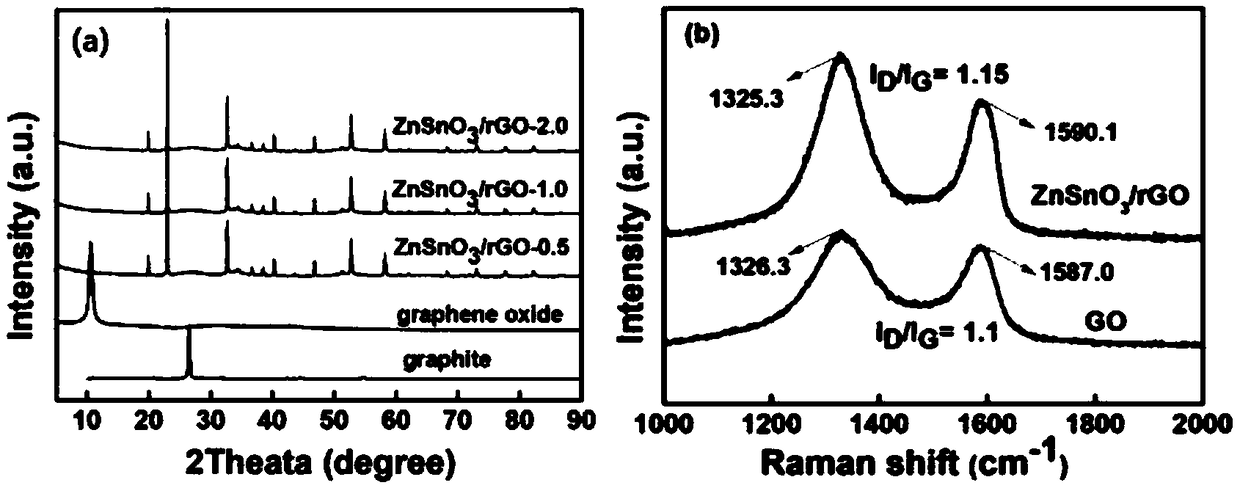

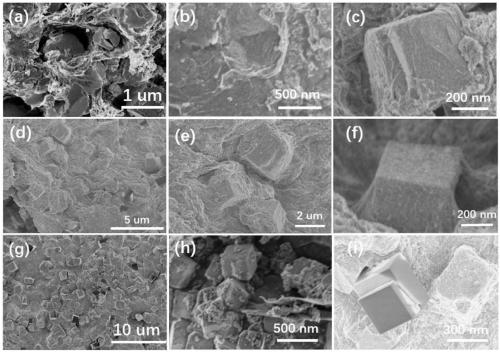

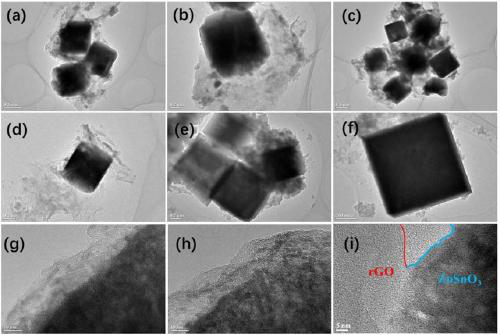

[0037] ZnSnO 3 Synthesis of @rGO composite material: The prepared graphene oxide (40mg) was added to a beaker filled with 60mL deionized water, and ultrasonicated for 2 hours. Then add equimo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com